Continuous spiral phase plate preparation method based on magneto-rheological machining

A helical phase plate and magnetorheological technology, which is applied in optics, instruments, optical components, etc., can solve the problems that the processing accuracy and efficiency cannot fully meet the requirements, it is difficult to effectively process large-diameter helical phase plates, and the production efficiency is low. Achieve high processing certainty, small function size and high forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

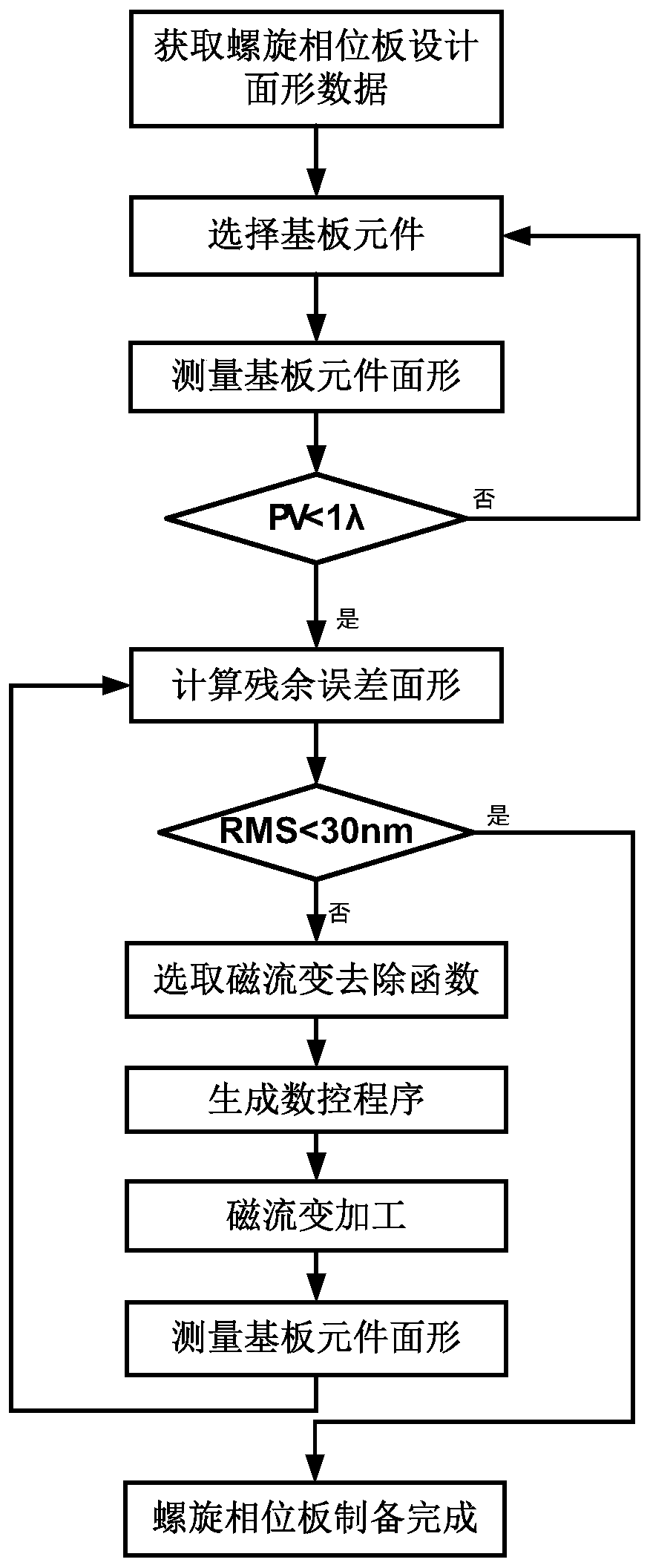

[0041] Please see attached figure 1 , the embodiment of the present invention discloses a continuous spiral phase plate preparation method based on magnetorheological processing, including:

[0042] S1: Obtain the design surface data of the spiral phase plate, where the design surface length is m, the design surface width is n, and the unit is mm;

[0043] S2: Select the substrate, wherein the length of the substrate is not less than m, and the width is not less than n; and measure the surface data of the substrate; judge whether the surface data of the substrate satisfies PV≤1λ; if so, execute step S3; where PV represents the surface data The difference between the maximum and minimum values in the middle;

[0044] When selecting the substrate, it is required that the geometric size of the substrate is not smaller than the design surface geometry of the spiral phase plate, otherwise the design pattern of the spiral phase plate cannot be completely processed on the substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com