Organosilicon-polyurea resin coating composition for protection and anti-explosion use, and construction method thereof

A technology of polyurea resin and composition, which is applied in the field of coatings, can solve problems such as personal injury and building damage, and achieve the effects of labor-saving operation, increased adhesion, and improved physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

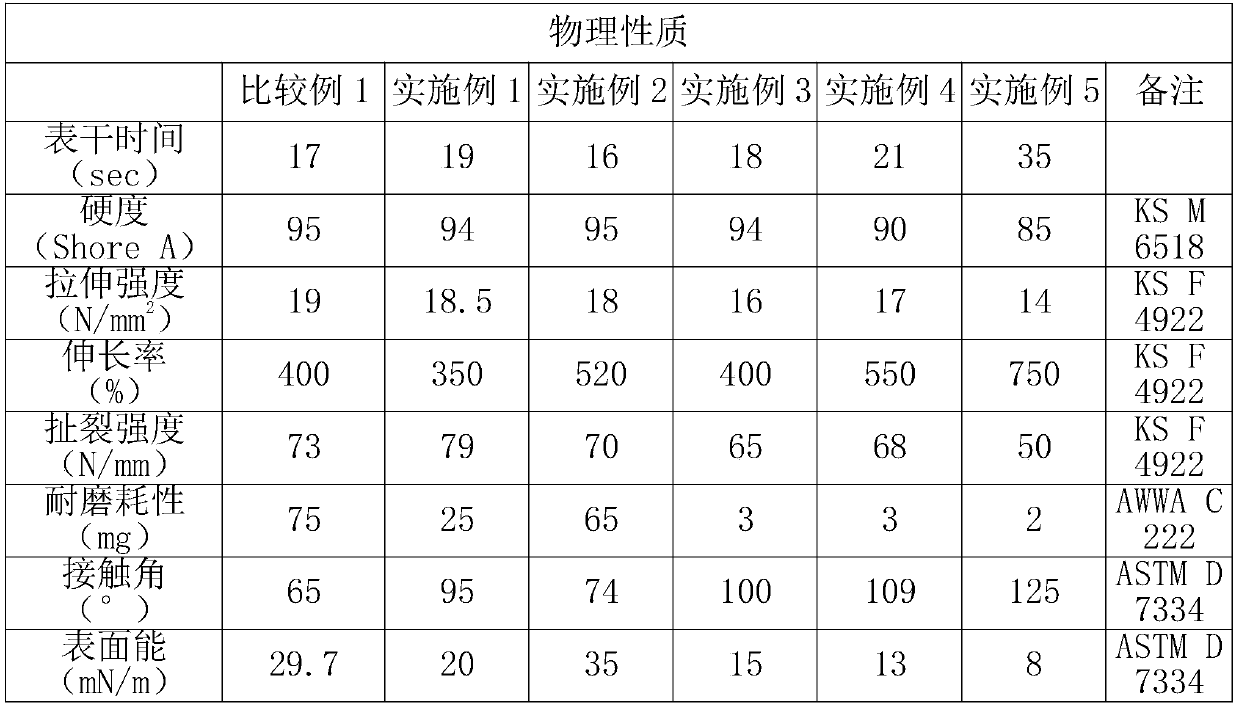

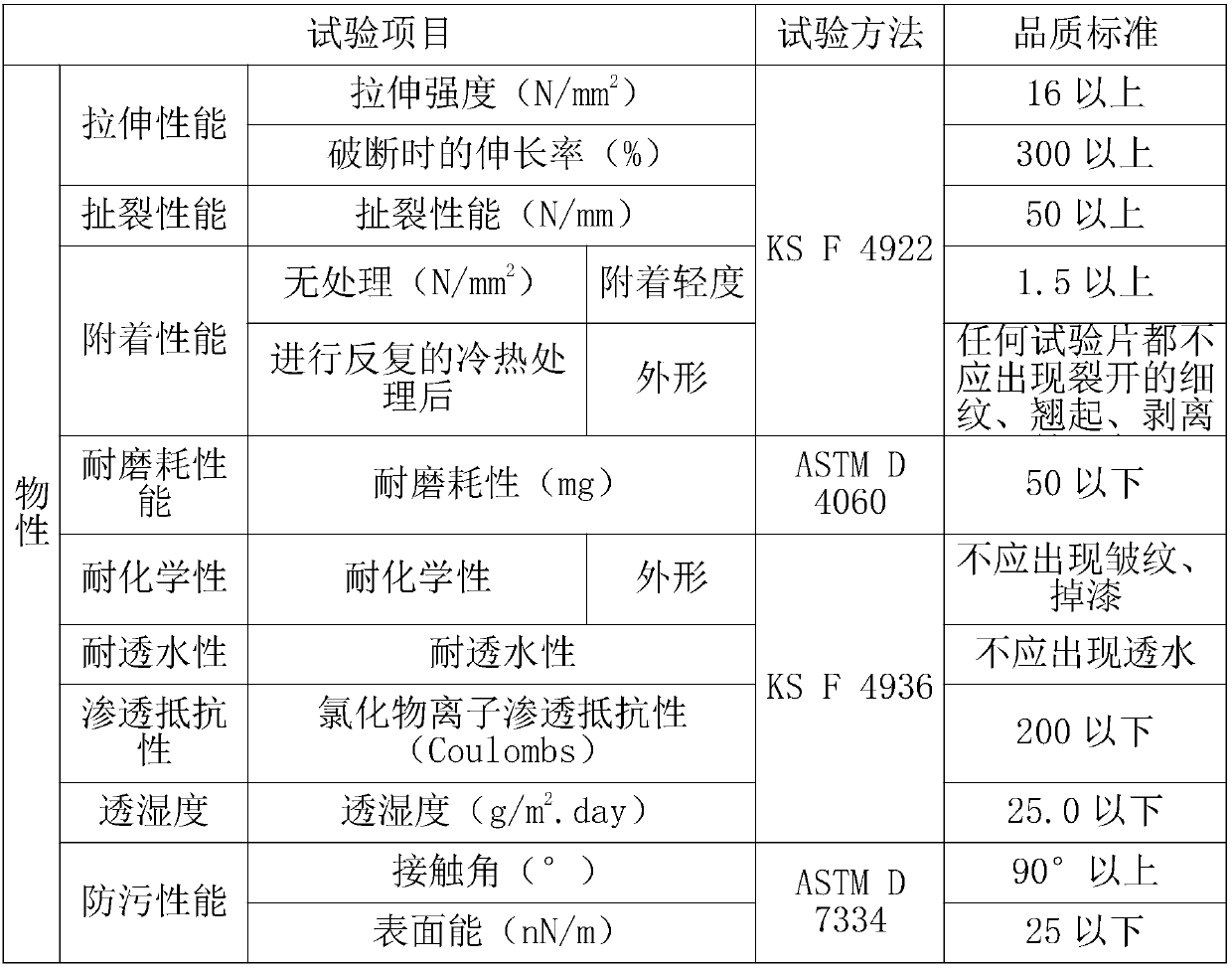

Examples

Embodiment 1

[0027] A silicone polyurea resin coating composition for protection against explosions, comprising a main agent and a curing agent, the main agent and the curing agent are mixed in a volume ratio of 1.13:1;

[0028] Wherein, the main agent includes: 67.8% of polyoxypropylene diamine, 19% of diethyltoluene diamine, 5% of pigment and filler, 1% of anti-ultraviolet agent, 1% of adhesion promoter, and 0.5% of dispersant according to weight percentage , stabilizer 0.2%, defoamer 0.5%, modified amino silicone oil 5%;

[0029] The curing agent is 100% by weight of isocyanate prepolymer.

[0030] Further, sequentially add 41 to 51 wt% of diphenylmethane diisocyanate with a molecular weight of 250.3, 44 to 49 wt% of polyols with a molecular weight of 2000 or polyether polyols with a molecular weight of 3000 to the reaction tank. React for 3-4 hours at 50-150rpm; add 5-15wt% phosphorus-based flame retardant, mix for 30-40 minutes at a temperature of 40-60°C and a stirring speed of 50-1...

Embodiment 2

[0044] A silicone polyurea resin coating composition for protection against explosions, comprising a main agent and a curing agent, the main agent and the curing agent are mixed in a volume ratio of 1.11:1;

[0045] Wherein, the main agent includes: 68.3% of polyoxypropylene diamine, 20.5% of diethyltoluene diamine, 5% of pigment and filler, 1% of anti-ultraviolet agent, 1% of adhesion promoter, and 0.5% of dispersant according to weight percentage , stabilizer 0.2%, defoamer 0.5%, modified amino silicone oil 3%;

[0046] The curing agent is 100% by weight of isocyanate prepolymer.

[0047] Further, sequentially add 43-55 wt% of carbodiimide-modified 4,4-diphenylmethane diisocyanate with a molecular weight of 285, 40-50 wt% of a polyol with a molecular weight of 2000 or a polyether polyol with a molecular weight of 3000, into the reaction tank, React for 3-4 hours at a temperature of 70-90°C and a stirring speed of 50-150rpm; add 5-15wt% phosphorus-based flame retardant, and ...

Embodiment 3

[0050] The silicone polyurea resin coating composition for protection and explosion-proof comprises a main agent and a curing agent, and the main agent and the curing agent are mixed in a weight ratio of 1.09:1;

[0051] Wherein, the main agent includes: 66.2% of polyoxypropylene diamine, 19.6% of diethyltoluene diamine, 5% of pigment and filler, 1% of anti-ultraviolet agent, 1% of adhesion promoter, and 0.5% of dispersant , stabilizer 0.2%, defoamer 0.5%, modified amino silicone oil 6%;

[0052] The curing agent is 100% by weight of isocyanate prepolymer.

[0053] Further, 15-35% by weight of diphenylmethane diisocyanate with a molecular weight of 250.3, carbodiimide-modified 4,4 diphenylmethane diisocyanate with a molecular weight of 285, and polyols with a molecular weight of 2000 or 3000 polyether polyol 40-50wt%, at a temperature of 70-90°C and a stirring speed of 50-150rpm, react for 3-4 hours; add phosphorus flame retardant 5-15wt%, stir at a temperature of 40-60°C, M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com