A kind of coating ink for ink-jet printing based on composite particle modification of multi-level structure and its preparation method and application

A composite particle, inkjet printing technology, applied in the direction of dyeing, textile and papermaking, etc., can solve the problems of complex preparation process, and achieve the effect of reducing the degree of infiltration, bright colors and clear patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

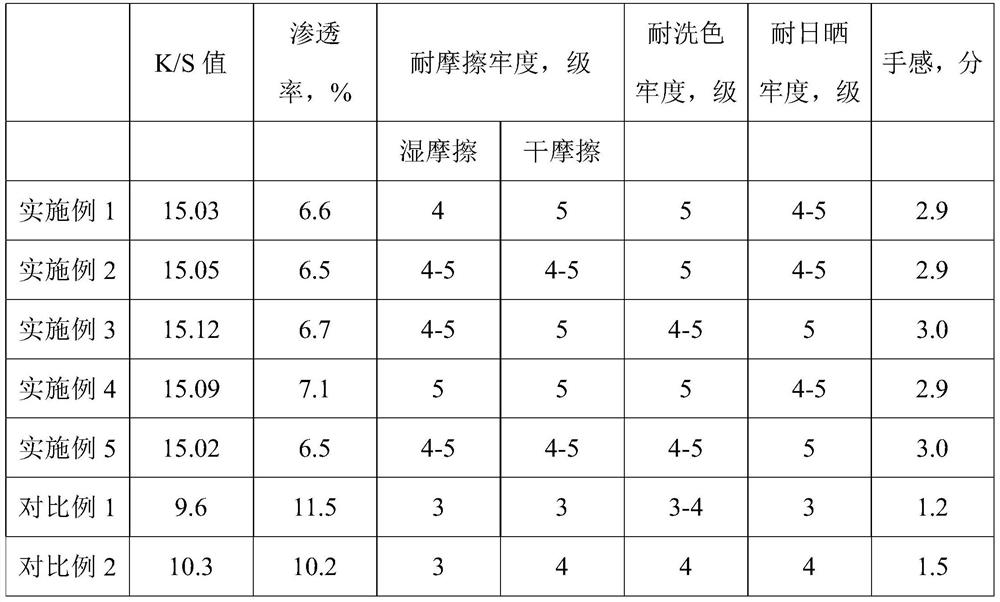

Embodiment 1

[0031] A kind of preparation method of ink-jet printing coating type ink that is modified based on the composite particle of multi-level structure, comprises the following steps:

[0032] (1) Dissolve zirconium isopropoxide in ethanol, then add polyvinyl alcohol aqueous solution with a mass concentration of 2%, stir at room temperature for 20 minutes at a speed of 1000 rpm, then add dropwise urea solution, and stir and mix at 40-50°C for 2 hours , to obtain a zirconium sol; wherein, the mass ratio of zirconium isopropoxide, polyvinyl alcohol, and urea is 4:0.026:0.2; dropwise adding a graphene oxide solution with a mass concentration of 1% in the zirconium sol, 3000rpm after the addition ends Stir at low temperature for 30 minutes, filter, wash the solid and dry it in vacuum at 80°C for 2h, then place it in a muffle furnace for calcination at 300-400°C for 3h, and then use the trap reduction method for reduction to obtain graphene nanosheet package Nano zirconia composite part...

Embodiment 2

[0038] A kind of preparation method of ink-jet printing coating type ink that is modified based on the composite particle of multi-level structure, comprises the following steps:

[0039] (1) Dissolve zirconium isopropoxide in ethanol, then add polyvinyl alcohol aqueous solution with a mass concentration of 2%, stir at room temperature for 20 minutes at a speed of 1000 rpm, then add dropwise urea solution, and stir and mix at 40-50°C for 2 hours , to obtain a zirconium sol; wherein, the mass ratio of zirconium isopropoxide, polyvinyl alcohol, and urea is 4:0.045:0.2; dropwise adding a graphene oxide solution with a mass concentration of 1-5% in the zirconium sol, the addition ends Finally, stir at 3000rpm for 60min, filter, wash the solid and vacuum dry it at 80°C for 2h, then place it in a muffle furnace for calcination at 300-400°C for 4h, and then use the trap reduction method to reduce it to obtain graphene nanoparticles. Sheet-coated nano-zirconia composite particles, the...

Embodiment 3

[0045] A kind of preparation method of ink-jet printing coating type ink that is modified based on the composite particle of multi-level structure, comprises the following steps:

[0046] (1) Dissolve zirconium isopropoxide in ethanol, then add polyvinyl alcohol aqueous solution with a mass concentration of 2%, stir at room temperature for 20 minutes at a speed of 1000 rpm, then add dropwise urea solution, and stir and mix at 40-50°C for 2 hours , make zirconium sol; Wherein, the mass ratio of zirconium isopropoxide, polyvinyl alcohol, urea is 4: 0.03: 0.2; Dropwise in zirconium sol, mass concentration is the graphene oxide solution of 2%, 3000rpm after dropping Stir at low temperature for 40 minutes, filter, wash the solid and dry it in vacuum at 80°C for 2 hours, then place it in a muffle furnace for calcination at 300-400°C for 3.5 hours, and then reduce it by trap reduction method to obtain graphene nanosheets Coated nano-zirconia composite particles, the mass ratio of gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com