Attapulgite/C2N one-dimensional/two-dimensional composite, preparation method and application

A technology of attapulgite and composite materials, applied in chemical instruments and methods, water/sludge/sewage treatment, chemical/physical processes, etc., to achieve simple preparation process, good chemical stability and environmental stability, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

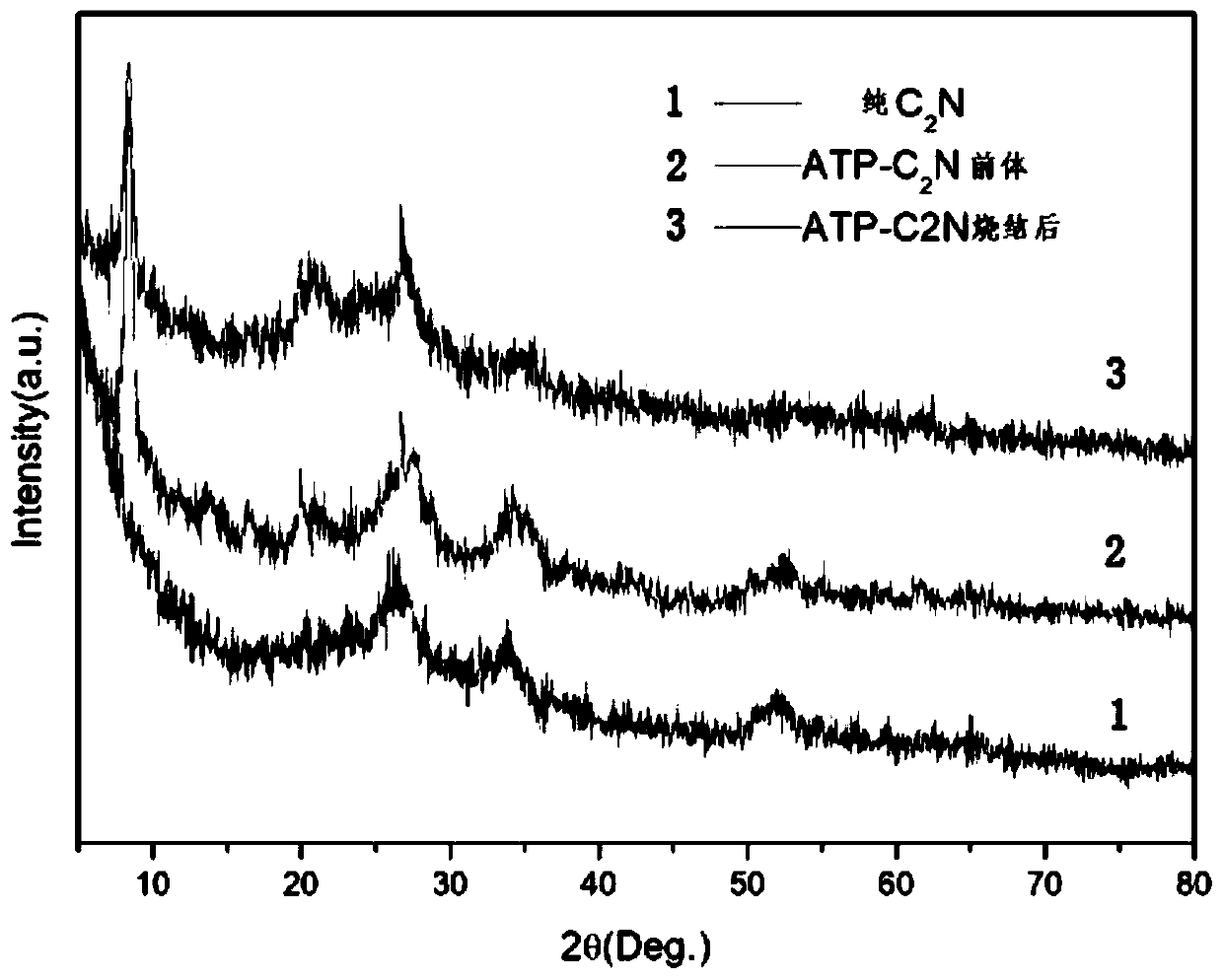

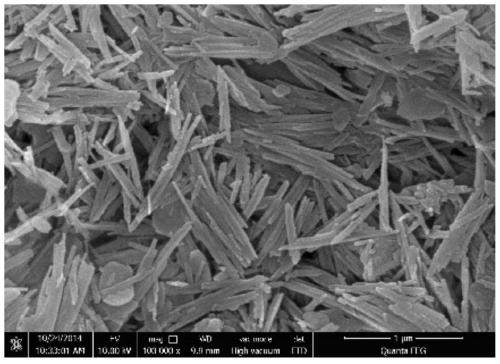

[0040] Embodiment 1: synthetic ATP / C 2 N-0.125 one-dimensional / two-dimensional composite materials:

[0041] (a) Attapulgite modification: Weigh 3g of dried attapulgite and 100mL of toluene into a four-neck flask in turn, stir at 60°C for 1 h, then add 2mL of silane coupling agent KH560, stir at 60°C for 2h, and then Wash with toluene and absolute ethanol, and dry at 60°C to obtain modified attapulgite (ATP-KH560).

[0042] (b) ATP / C 2 Preparation of N one-dimensional / two-dimensional composite materials: Weigh 0.4g modified attapulgite, 80mL methylpyrrolidone, 0.05g hexaaminobenzene trihydrochloride and 80mL concentrated sulfuric acid into a four-necked flask under an ice-water bath, and in N 2 Mix and stir for 4 hours under the atmosphere, transfer the mixed solution to a 70°C oil bath after reaching room temperature, and reflux at this temperature for 2 hours;

[0043] (c) Then add 0.056g hexaketonecyclohexane octahydrate and stir for 2h, finally add deionized water and ...

Embodiment 2

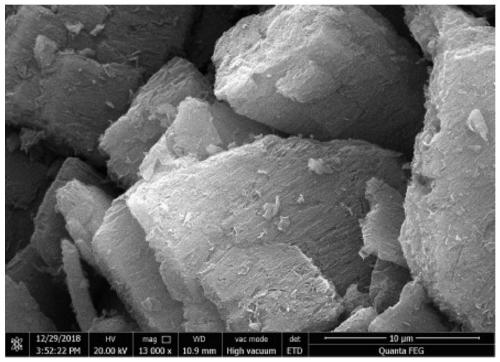

[0044] Embodiment 2: synthetic ATP / C 2 N-0.25 one-dimensional / two-dimensional composite materials:

[0045](a) Attapulgite modification: Weigh 6g of dried attapulgite and 100mL of toluene into a four-necked flask in turn, stir at 80°C for 0.5h, then add 5mL of silane coupling agent KH560, stir at 80°C for 2h, and then Wash with toluene and absolute ethanol, and dry at 60°C to obtain modified attapulgite (ATP-KH560);

[0046] (b) ATP / C 2 Preparation of N one-dimensional / two-dimensional composite materials: Weigh 0.4g modified attapulgite, 80mL methylpyrrolidone, 0.1g hexaaminobenzene trihydrochloride and 80mL concentrated sulfuric acid into a four-neck flask under an ice-water bath, and in N 2 Mix and stir for 2 hours under the atmosphere, transfer the mixed solution to an oil bath at 80°C after reaching room temperature, and reflux at this temperature for 2 hours;

[0047] (c) Then add 0.11g of hexaketonecyclohexane octahydrate and stir for 4 hours, finally add deionized w...

Embodiment 3

[0048] Embodiment 3: synthetic ATP / C 2 N-0.375 one-dimensional / two-dimensional composite materials:

[0049] (a) Attapulgite modification: Weigh 10g of dried attapulgite and 120mL of toluene into a four-neck flask in turn, stir at 60°C for 1h, then add 8mL of silane coupling agent KH560, stir at 60°C for 2h, then use Wash with toluene and absolute ethanol, and dry at 60°C to obtain modified attapulgite (ATP-KH560).

[0050] (b) ATP / C 2 Preparation of N one-dimensional / two-dimensional composite materials: Weigh 0.4g modified attapulgite, 80mL methylpyrrolidone, 0.15g hexaaminobenzene trihydrochloride and 80mL concentrated sulfuric acid into a four-neck flask under an ice-water bath, and in N 2 Mix and stir for 2 hours under the atmosphere, transfer the mixed solution to an oil bath at 80°C after reaching room temperature, and reflux at this temperature for 2 hours;

[0051] (c) Then add 0.17g hexaketonecyclohexane octahydrate and stir for 4h, finally add deionized water and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com