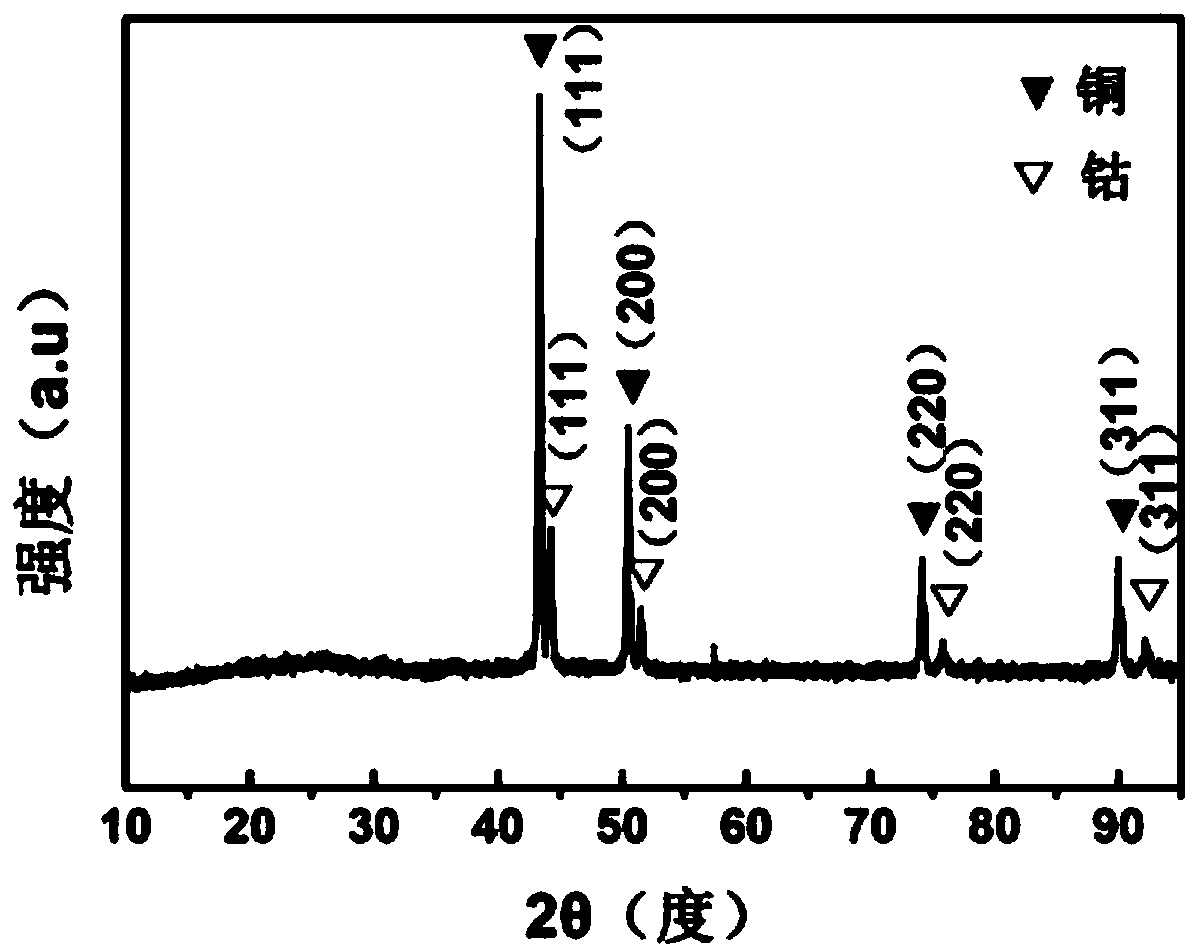

Copper-cobalt bimetal/porous carbon nanofiber composite material, and preparation method and application thereof

A nanofiber and composite material technology is applied in the field of preparation of copper-cobalt bimetallic/porous carbon nanofiber composite materials, which can solve the problems of low specific surface area of composite catalysts, insufficient utilization of active sites, and poor compound adsorption capacity. To achieve good acid and alkali resistance catalytic effect, improve the ability to degrade organic pollutants, and promote the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of copper-cobalt double metal / porous carbon nanofiber composite material, its preparation method comprises the steps:

[0040] 1) Add 6mmol of copper acetate, 2mmol of cobalt acetate, 1g of biomass tar and 2g of polyacrylonitrile into 18g of N,N-dimethylformamide (DMF) solution, and stir evenly to obtain the electrospinning precursor solution;

[0041] 2) Place the electrospinning precursor solution obtained in step 1) in a 10ml syringe with a needle, the voltage is 20kV DC high voltage, and the distance between the needle and the receiving plate is 15cm; the flow rate of the precursor solution is controlled by a syringe pump The humidity is 1.0ml / h; the humidity of the environment during the electrospinning process is 30-50%; copper acetate / cobalt acetate / biomass tar / polyacrylonitrile composite nanofibers are obtained by electrospinning;

[0042] 3) Put the composite nanofibers obtained in step 2) into a tube furnace, firstly preheat and oxidize at 240°C in air...

Embodiment 2

[0056] 1) Add 2mmol of copper acetate, 6mmol of cobalt acetate, 0.5g of biomass tar and 2g of polyacrylonitrile into 13.4g of N,N-dimethylformamide (DMF) solution, stir evenly, and obtain electrospun Precursor solution;

[0057] 2) Place the electrospinning precursor solution obtained in step 1) in a 10ml syringe with a needle, the voltage is 20kV DC high voltage, and the distance between the needle and the receiving plate is 15cm; the flow rate of the precursor solution is controlled by a syringe pump The humidity is 1.0ml / h; the humidity of the environment during the electrospinning process is 30-50%; copper acetate / cobalt acetate / biomass tar / polyacrylonitrile composite nanofibers are obtained by electrospinning;

[0058] 3) Put the composite nanofibers obtained in step 2) into a tube furnace, firstly preheat and oxidize at 240°C in air for 3h (heating rate is 1°C / min); then use nitrogen as a protective gas and carbonize at 800°C for 2h (The heating rate is 5°C / min); finall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com