A kind of fatty alcohol block polyether, dispersant for pesticide aqueous suspension, preparation method thereof, pesticide aqueous suspension

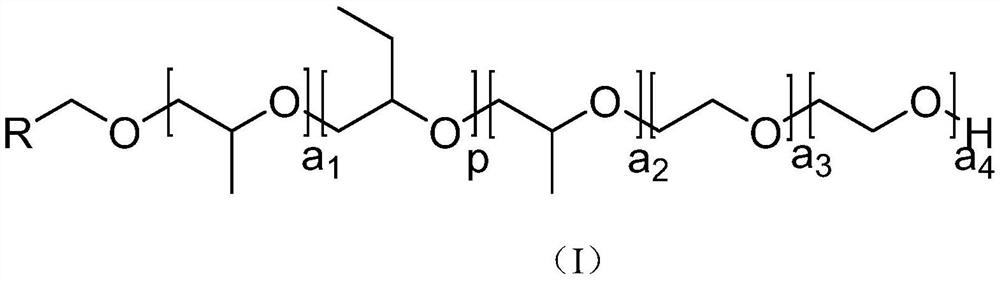

A block polyether and fatty alcohol technology, applied in the field of polymers, can solve the problems that the pesticide water suspension cannot meet the production, storage and use, etc., and achieve the goal of improving low temperature antifreeze ability, improving hydrophilicity and excellent fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

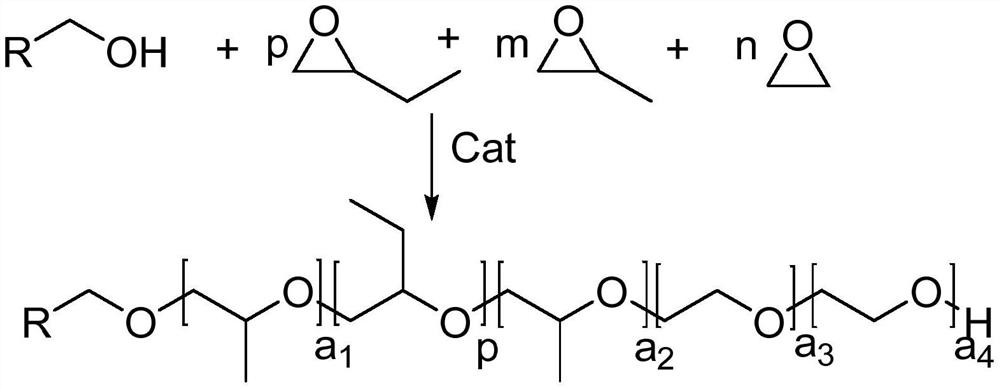

Method used

Image

Examples

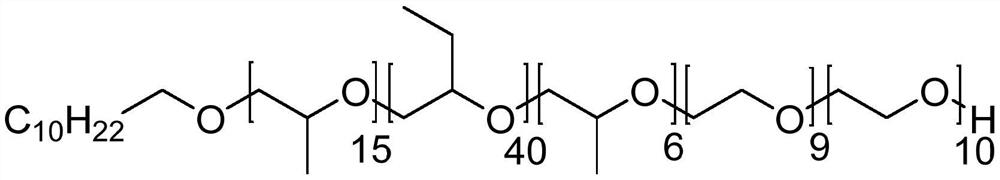

Embodiment 1

[0036] A kind of preparation method for the dispersant of agricultural chemicals water suspension concentrate, operation steps are as follows:

[0037] (1) Get initiator isomerization undecyl alcohol (1mol), propylene oxide (15mol), basic catalyst KOH (0.001mol), the starter butanol is at 120 ℃, 0.50MPa, basic catalyst KOH Ring-opening polymerization reaction occurs with propylene oxide under the action to obtain intermediate product 1;

[0038] (2) The intermediate product 1 obtained in step (1) is neutralized with phosphoric acid to pH = 7, and is decomposed with butylene oxide (40 mol) at 170 ° C, 0.50 MPa, and under the action of a bimetallic catalyst DMC (0.015 mol). Ring polymerization reaction to obtain intermediate product 2;

[0039] (3) Continue to add the basic catalyst KOH (0.001mol) in the intermediate product 2, and first react with propylene oxide (6mol) under the conditions of 120°C and 0.50MPa for ring-opening polymerization, and then react with ethylene oxid...

Embodiment 2

[0044] A kind of preparation method for the dispersant of agricultural chemicals water suspension concentrate, operation steps are as follows:

[0045] (1) Get initiator isomeric tridecanol (1mol), propylene oxide (25mol), basic catalyst KOH (0.005mol), the initiator butanol is at 120 ℃, 0.5MPa, basic catalyst KOH Ring-opening polymerization reaction occurs with propylene oxide under the action to obtain intermediate product 1;

[0046] (2) The intermediate product 1 obtained in step (1) is neutralized with phosphoric acid to pH = 6, and is developed with butylene oxide (60 mol) under the action of a bimetallic catalyst DMC (0.015 mol) at 170 ° C and 0.5 MPa. Ring polymerization reaction to obtain intermediate product 2;

[0047] (3) Continue to add the basic catalyst KOH (0.005mol) to the intermediate product 2, and undergo ring-opening polymerization (random polymerization) with ethylene oxide (5mol) and propylene oxide (15mol) at 160°C and 0.5MPa. ) reaction to obtain int...

Embodiment 3

[0052] A kind of preparation method for the dispersant of agricultural chemicals water suspension concentrate, operation steps are as follows:

[0053] (1) Get initiator butanol (5mol), propylene oxide (25mol), basic catalyst KOH (0.025mol), the initiator butanol is mixed under the effect of 110 ℃, 0.30MPa, basic catalyst KOH Propylene oxide undergoes ring-opening polymerization to obtain intermediate product 1;

[0054] (2) Neutralize the intermediate product 1 obtained in step 1 to pH = 6, and undergo ring-opening polymerization with butylene oxide (55 mol) at 150° C., 0.40 MPa, and under the action of a bimetallic catalyst DMC (0.065 mol). Reaction, obtain intermediate product 2;

[0055] (3) Continue to add the basic catalyst KOH (0.025mol) in the intermediate product 2, and first react with propylene oxide (15mol) under the conditions of 150°C and 0.5MPa for ring-opening polymerization, and then react with ethylene oxide (15mol) ) ring-opening polymerization reaction oc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com