Perovskite oxide thin-film device, preparation method thereof and application thereof

A perovskite oxide and thin-film device technology, applied in the direction of electrical components, can solve problems such as the contradiction between erasing and writing speed and reliability, gate dielectric leakage, and limit the development of Flash memory, and achieve uniform surface microstructure, fewer holes, Ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

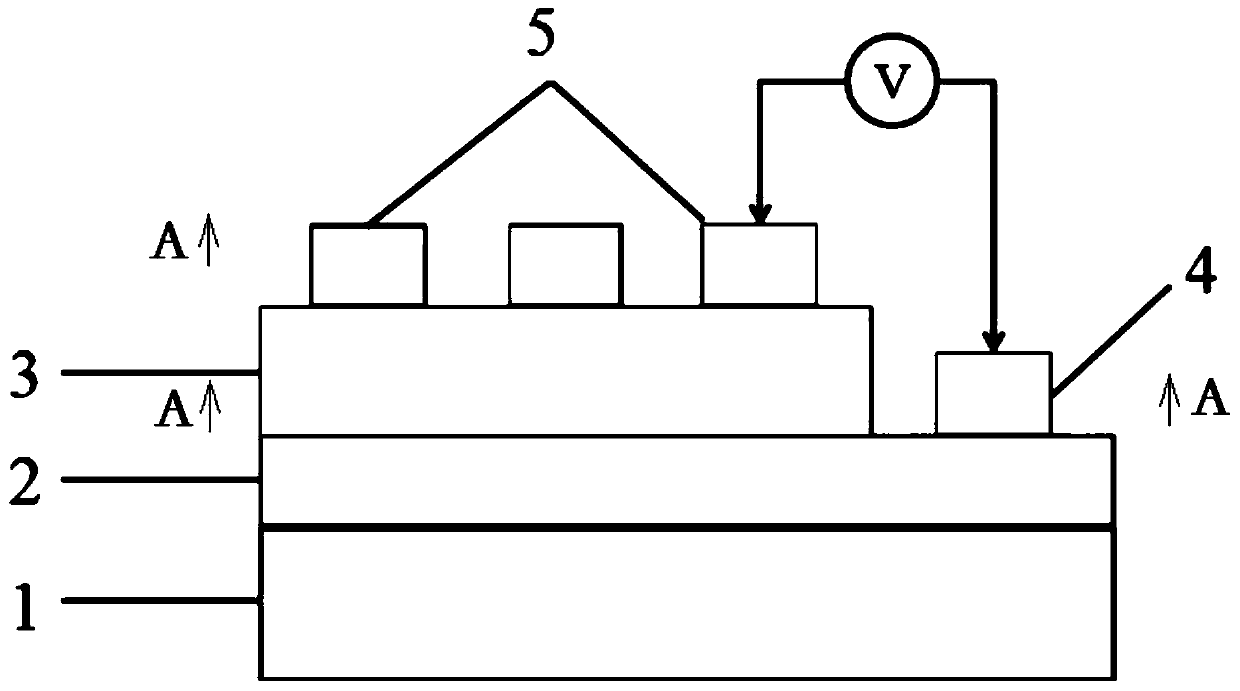

[0059] Specifically, the embodiment of the present application provides a method for preparing a perovskite oxide thin film device, including the following steps:

[0060] Step 1. According to the sol-gel method, the magnetron sputtering method, and the pulsed laser deposition method, the material of the bottom electrode layer is arranged on the surface of the base layer;

[0061] Step 2, according to sol-gel method, magnetron sputtering method, pulsed laser deposition method, PbZrO 3 layer is disposed on the surface of the bottom electrode on the side away from the base layer;

[0062] Step 3. Set the first top electrode on PbZrO 3 layer facing away from the surface of the side of the bottom electrode layer;

[0063] Step 4, disposing the second top electrode on the surface of the bottom electrode layer facing away from the base layer.

[0064] Among them, the sol-gel method, magnetron sputtering method or pulsed laser deposition method are all existing conventional method...

Embodiment 1

[0067] The embodiment of the present application adopts the sol-gel method to prepare perovskite oxide thin film devices, and the specific preparation process includes:

[0068] 1. Preparation of LaNiO 3 precursor solution and PbZrO 3 The precursor solution:

[0069] NeO 3 Precursor solution: the precursor solution is prepared with lanthanum nitrate hexahydrate La(NO 3 )36H 2 O, nickel acetate Ni(CH 3 COO) 24 h 2 O as a raw material was dissolved in ethylene glycol methyl ether and glacial acetic acid, respectively, and kept stirring at 50 °C until completely dissolved. When the temperature of the two bottles of solution drops to room temperature and there is no precipitation, mix the two solutions again, add acetylacetone dropwise as a stabilizer, and continue stirring at 50°C for 1 hour. After a completely clear and transparent solution is formed, use Ethylene glycol methyl ether and acetylacetone set the concentration of the solution to 0.25mol / L, and it can be used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com