Battery composite material and preparation method thereof, electrode sheet and battery

A composite material and battery technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of poor cycle performance and rapid capacity depletion of tin dioxide batteries, achieve high specific capacity, solve poor cycle performance, Resolving the effect of rapid volume exhaustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

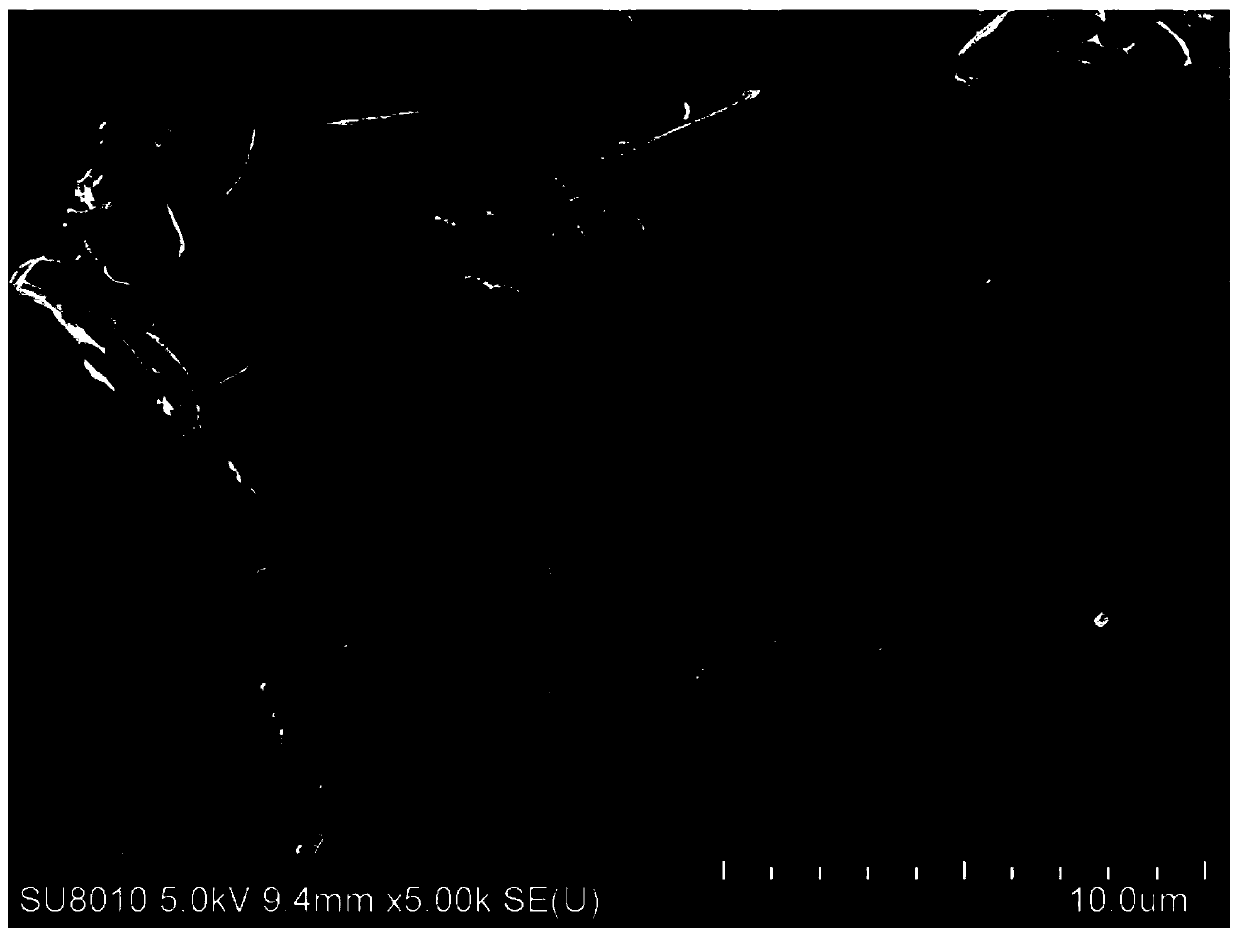

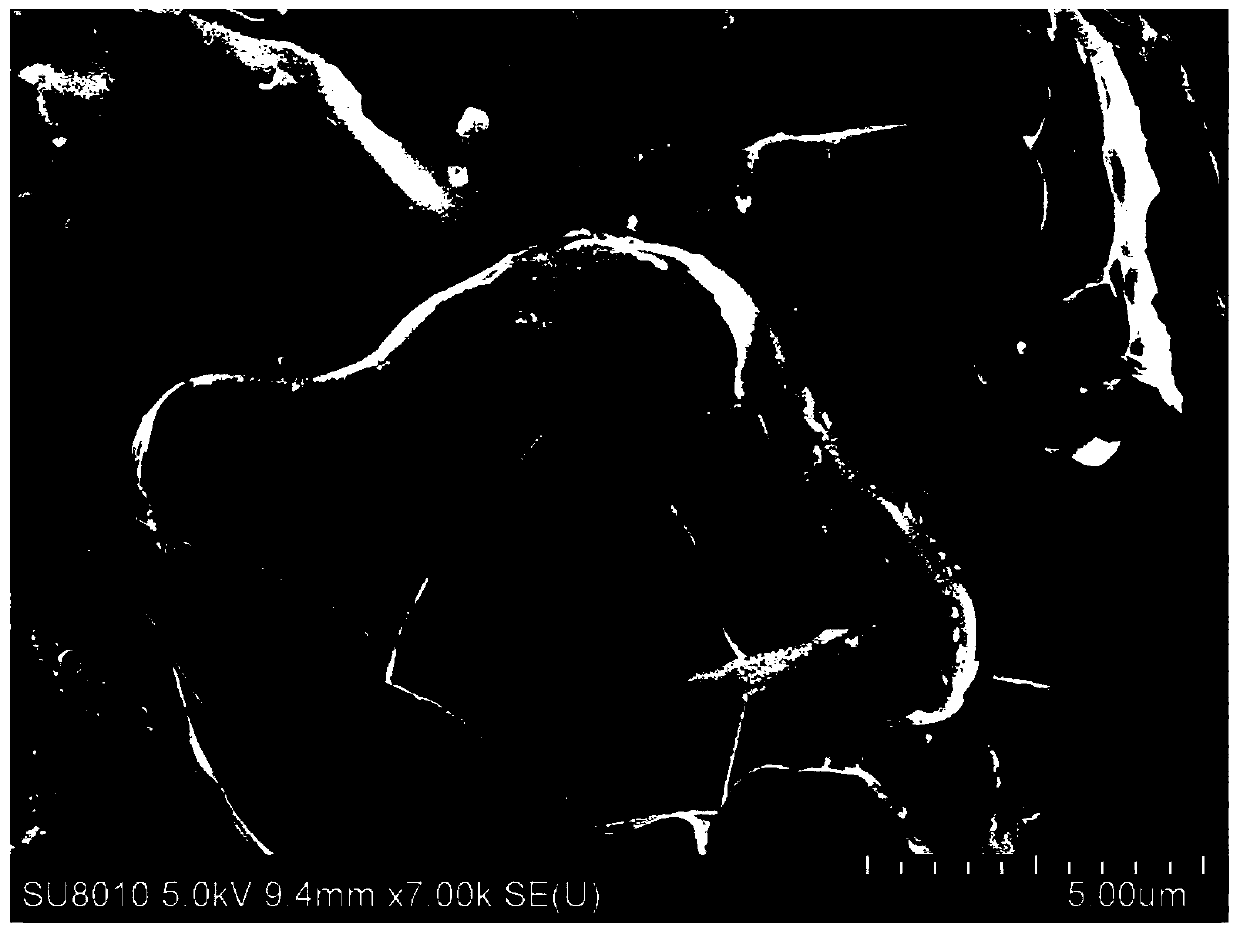

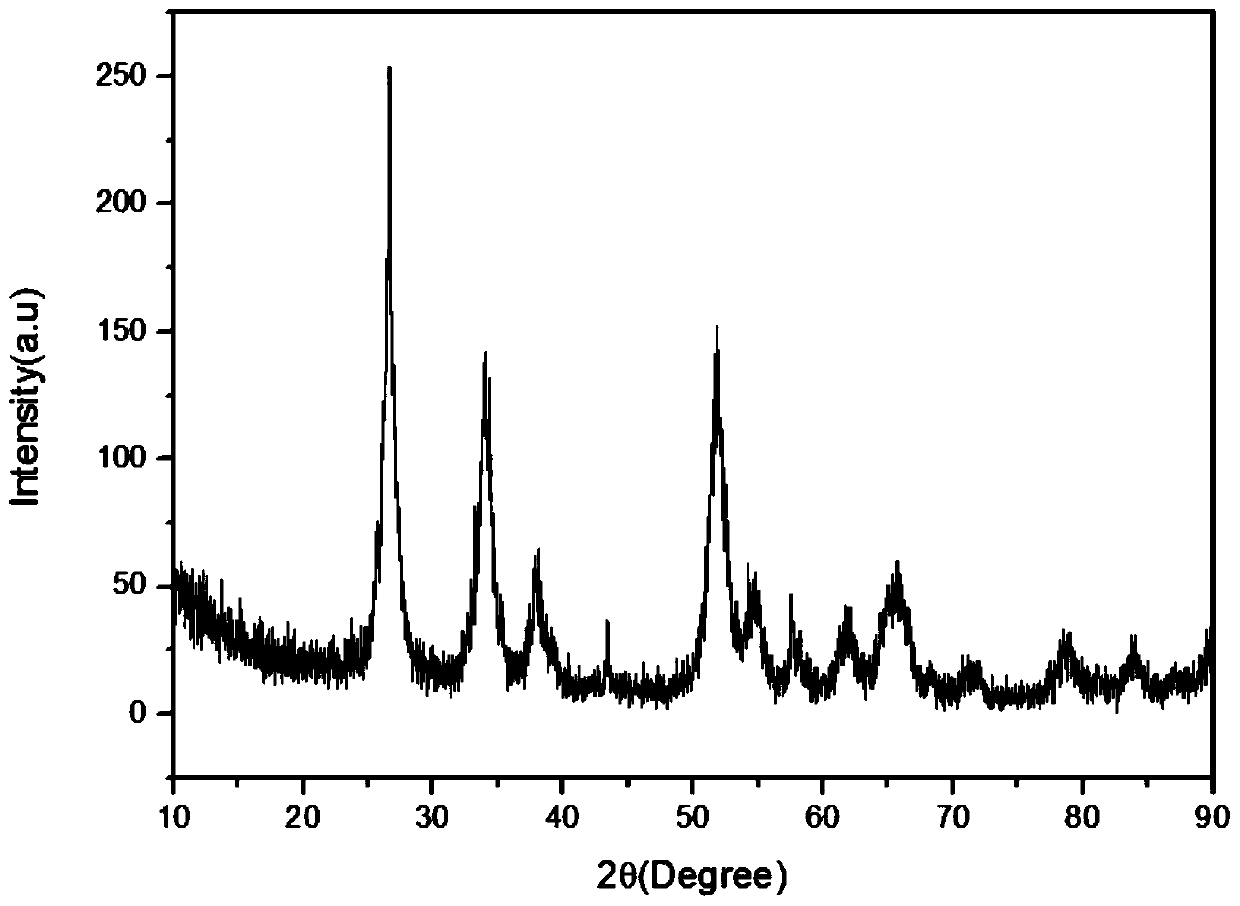

Embodiment 1

[0041] The embodiment of the present application provides the first battery, and the specific steps are as follows:

[0042] 1. Make a mixed solution of 0.4g tin dioxide, 2g citric acid, 0.2g polyvinylidene fluoride, 14g sodium chloride and 50ml deionized water, put a stirring bar in the solution, put it in a beaker, and put it in a magnetic stirrer Stir on for 1h. The obtained solution was put into a ball mill jar and ball milled for 20 hours without interruption in one direction to obtain a mixture.

[0043] 2. Put the mixture in step 1 into a drying oven at 80° C. to dry to obtain a precipitate, and put the obtained precipitate into a mortar and grind it into tiny particles.

[0044] 3. Put the tiny precipitate in step 2 into the porcelain ark, and use nitrogen as a protective gas to calcinate in a calcination furnace at 500° C. for 2 hours to obtain a battery composite material.

[0045] 4. In order to remove impurities in the battery composite material, the battery comp...

Embodiment 2

[0050] The embodiment of the present application provides the second battery, and the specific steps are as follows:

[0051] 1. Make a mixed solution of 0.4g tin dioxide, 2g citric acid, 0.2g polyvinylidene fluoride, 14g sodium chloride and 50ml deionized water, put a stirring bar in the solution, put it in a beaker, and put it in a magnetic stirrer Stir on for 1h. The obtained solution was put into a ball mill jar and ball milled for 20 hours without interruption in one direction to obtain a mixture.

[0052] 2. Put the mixture in step 1 into a drying oven at 80° C. to dry to obtain a precipitate, and put the obtained precipitate into a mortar and grind it into tiny particles.

[0053] 3. Put the tiny precipitate in step 2 into the porcelain ark, and use nitrogen as a protective gas to calcinate in a calciner at 700°C for 2 hours to obtain a battery composite material.

[0054] 4. In order to remove impurities in the battery composite material, the battery composite materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com