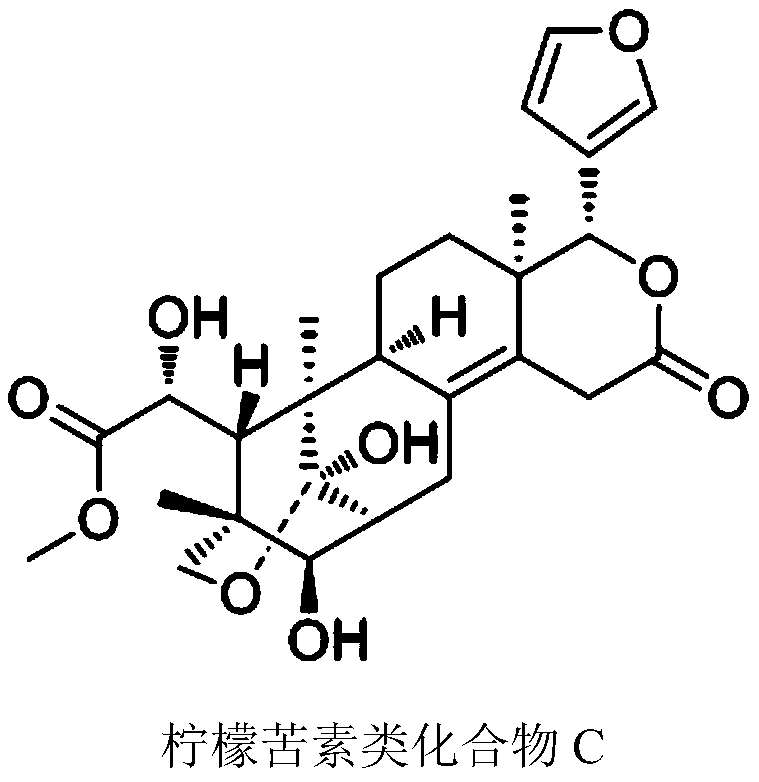

Separation and purification method of limonin compound C in Fructus Swietenia Macrophylla

A technology for the separation and purification of limonoids, which is applied in the direction of organic chemistry, can solve the problems of low extraction rate and cumbersome extraction methods, and achieve the effects of high extraction rate and purity, short time and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

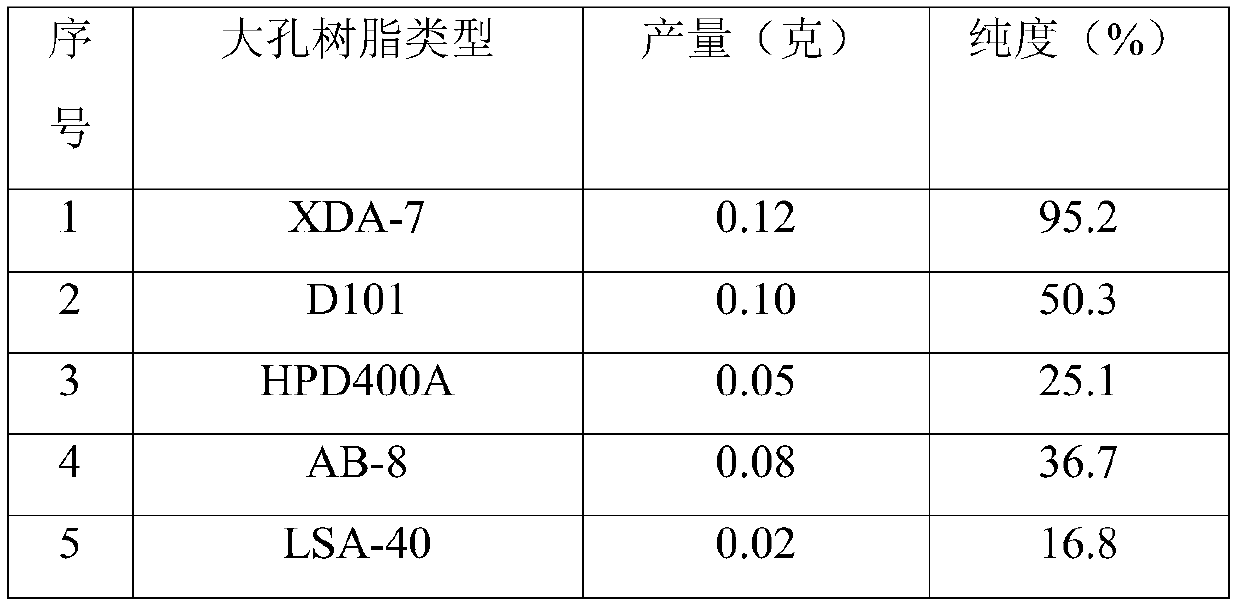

[0018] Take 50g of dried Xiangtianguo, crush it through a 200-mesh sieve to obtain powder; add the powder to 250mL methanol, extract for 2 hours with a Soxhlet extractor, filter, and take the supernatant; add the supernatant to 500g macropore In the adsorption resin XDA-7, adsorb for 3 hours, wash the resin column three times with 1.5L of water, and then elute with a mixed solvent of ethanol-acetone-n-hexane with a volume ratio of 6:3:1, collect the eluate, and concentrate under reduced pressure. Obtain the initial product; the initial product is dissolved with 20mL of ethanol under reflux, placed to crystallize, filtered and then washed twice with petroleum ether and dried to obtain 0.12g of white powder limonoid compound C, and the reference standard is detected by high performance liquid phase. The characteristic front positions are the same, and the calculated content is 95.2%. MS: 503.2[M+H] + . 1 H-NMR (CDCl 3 ,300MHz) δ: 2.10d(3-OH), 2.58br s(1-OH), 2.96br s(6-OH). ...

Embodiment 2

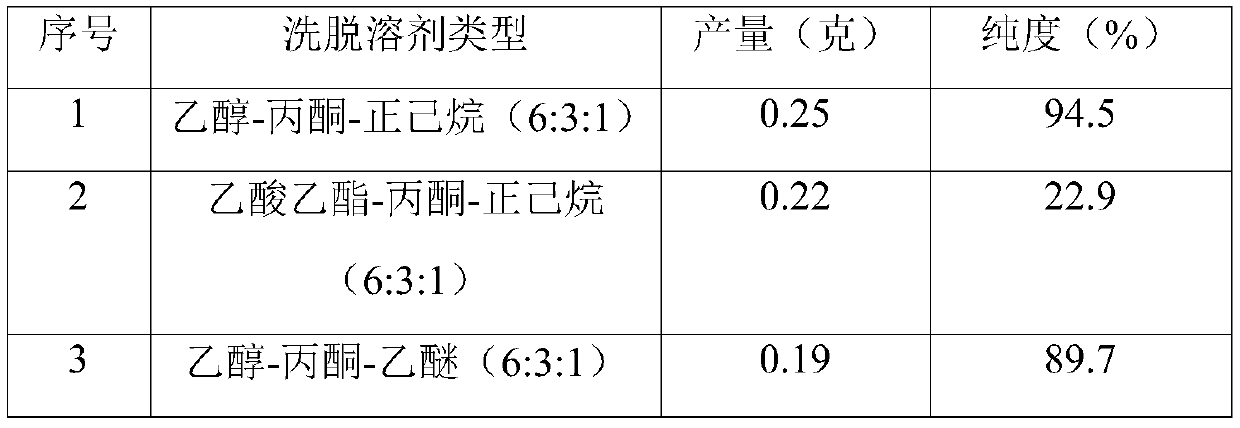

[0024] Take 100g of dried Xiangtianguo, crush it through a 200-mesh sieve to obtain a powder; add the powder to 500mL of ethanol, use a Soxhlet extractor to extract for 3 hours, filter, and take the supernatant; add the supernatant to 1kg macropore In the adsorption resin XDA-7, adsorb for 2 hours, wash the resin column three times with 3L of water, and then elute with a mixed solvent of ethanol-acetone-n-hexane with a volume ratio of 6:3:1, collect the eluate, and concentrate under reduced pressure to obtain The initial product: the initial product was dissolved with 40 mL of ethanol under reflux, placed to crystallize, filtered, washed twice with ether and dried to obtain 0.25 g of white powder limonoid compound C, the content of which was 94.5% by HPLC.

[0025] Screening experiment of elution solvent: the same method as in Example 2 was adopted, the difference being that the type and ratio of the elution solvent were replaced, and the results obtained are shown in Tables 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com