Nano C-S-H gel super-early strength agent and preparation method thereof

A C-S-H, early strength agent technology, applied in the field of concrete admixtures, can solve problems such as difficult to control the dosage, reduced durability, corrosion of steel bars, etc., and achieve the effects of promoting crystal growth, functional group coordination, and high water reducing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

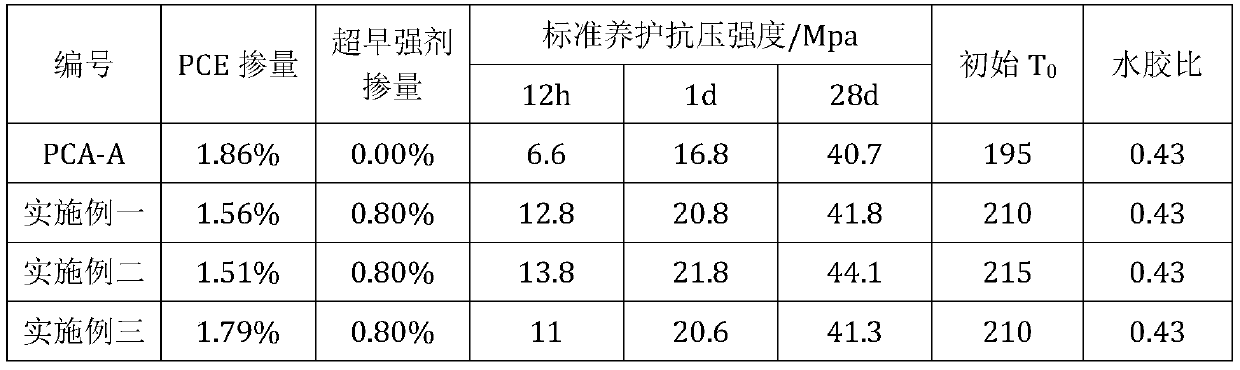

Embodiment 1

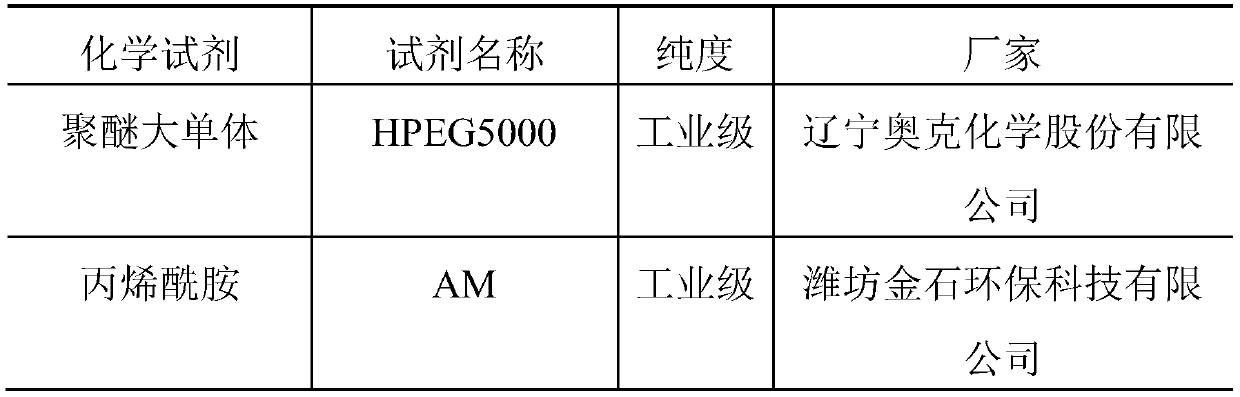

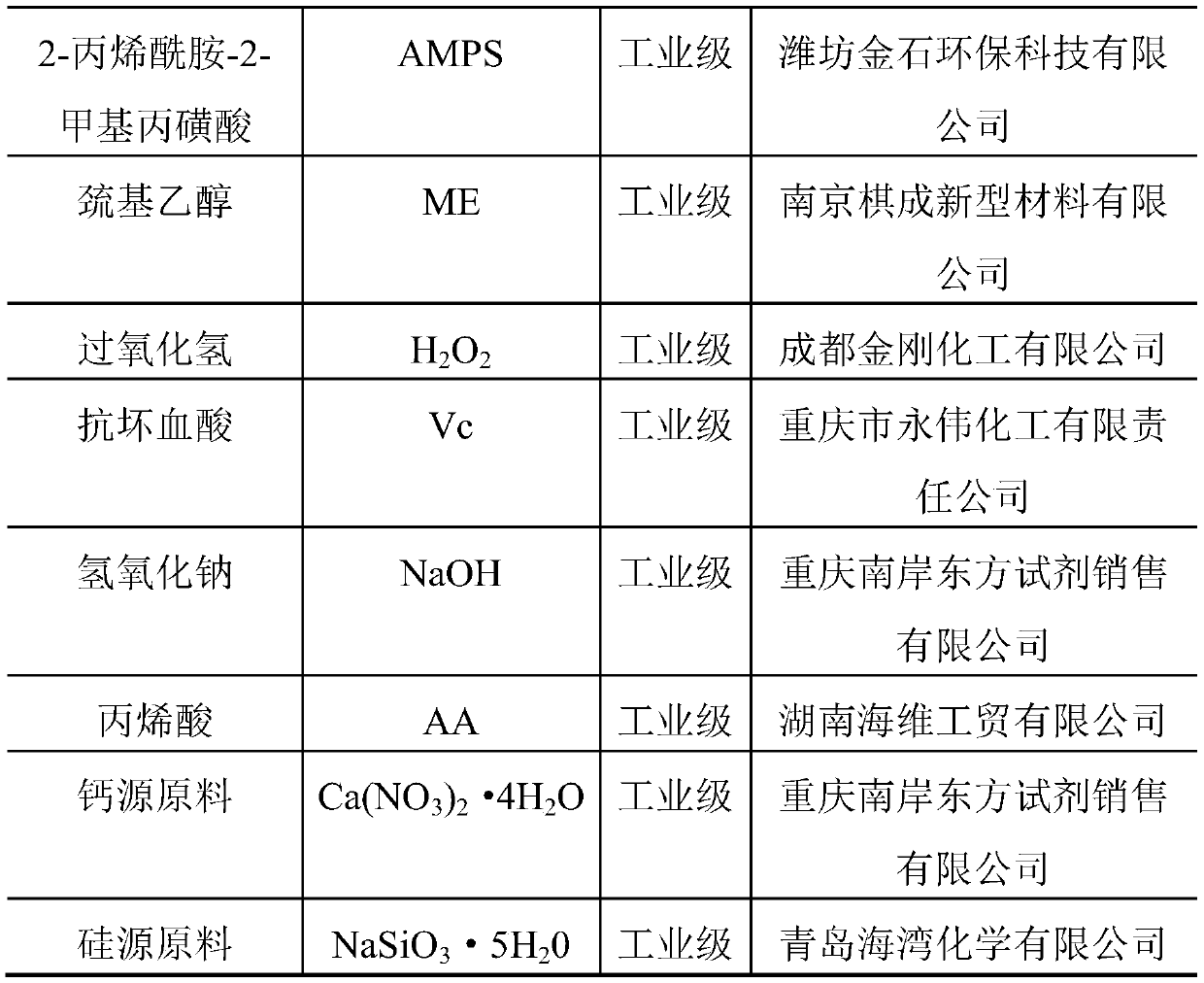

[0067] A. Weigh 400g of isobutylene alcohol polyoxyethylene ether with a weight average molecular weight of 5000 and 400g of water into the reaction kettle, start the stirring device at a speed of 250rpm, heat to 40°C, weigh 0.5g of ascorbic acid, 2g of mercaptoethanol, and add 100g Prepare solution E in water for later use; weigh 36.0g of acrylic acid, 1.0g of acrylamide, and 5.0g of 2-acrylamide-2-methylpropanesulfonic acid, add it to 100g of water, and prepare for later use as solution F. After the temperature is stable, take by weighing 3.5g30% hydrogen peroxide aqueous solution, add in the reactor, drip solution E, solution F simultaneously in the reactor after 5 minutes, the dripping time of solution E is 210 minutes, the solution F The dropwise addition time was 180 minutes. After the dropwise addition is completed, keep warm and continue to stir for 1 hour. After the reaction is completed, add 30% NaOH solution to adjust the pH value to 6.9 to obtain an early-strength ...

Embodiment 2

[0072] A. Weigh 400g of isobutylene alcohol polyoxyethylene ether with a weight average molecular weight of 5000 and 400g of water into the reaction kettle, start the stirring device at a speed of 250rpm, heat to 40°C, weigh 0.5g of ascorbic acid, 2g of mercaptoethanol, and add 100g In water, prepare solution E for later use; weigh 40.0g of acrylic acid, 1.0g of acrylamide, and 5.0g of 2-acrylamide-2-methylpropanesulfonic acid, add it to 100g of water, and prepare for later use as solution F. After the temperature is stable, take by weighing 3.5g30% hydrogen peroxide aqueous solution, add in the reactor, drip solution E, solution F simultaneously in the reactor after 5 minutes, the dripping time of solution E is 210 minutes, the solution F The dropwise addition time was 180 minutes. After the dropwise addition is completed, keep warm and continue to stir for 1 hour. After the reaction is completed, add 30% NaOH solution to adjust the pH value to 6.9 to obtain an early-strength...

Embodiment 3

[0077] A. The weight and preparation method of each component of the early-strength polycarboxylate high-performance water reducer are the same as in Example 2.

[0078] B. Weigh 100g of the early-strength polycarboxylate superplasticizer obtained in step A, dissolve it in 300g of water, add 30% NaOH, adjust the pH value to 13.5, and stir to obtain solution A for use; weigh 130g of calcium nitrate tetrahydrate , 120g of sodium metasilicate pentahydrate were dissolved in 100g and 220g of water respectively, and stirred evenly to obtain solution B and solution C for later use.

[0079] C. Add solution A to the reaction kettle, and add 3.0g diethanol monoisopropanolamine, turn on the stirring device to stir evenly, the rotation speed is 500rpm, and start the temperature controller to heat to 60°C, and drop solution A and solution B at the same time , The dropping time is 3h.

[0080] D. Insulate and keep stirring for 1 hour. After the reaction, the material is discharged to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com