Copper-based composite conductive paste, preparation method and application thereof

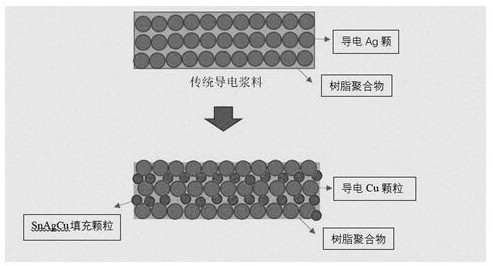

A conductive paste and copper-based composite technology, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problems of poor conductivity, narrow selection of printing substrate materials, and conductive copper paste. Solve problems such as high curing temperature to achieve the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

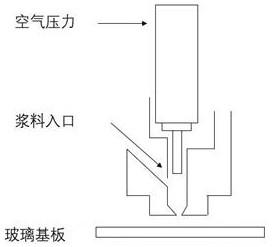

[0036] (1) Take 7 parts of spherical copper powder of about 6 μm and 3 parts of SnAgCu alloy powder of about 3 μm and mix thoroughly to obtain a composite conductive filler.

[0037] (2) Take 3.98 parts of triethanolamine as a curing agent, and sequentially add 0.2 parts of 2-ethyl-4 methylimidazole, 0.4 parts of 3-aminopropyltriethoxysilane, 2.5 parts of twelve to ten Tetraglycidyl ether, 1 part of tributyl phosphate, 0.42 part of ascorbic acid, 0.7 part of polyethylene glycol, and 0.8 part of NA acid anhydride are fully stirred to obtain an organic carrier system.

[0038] (3) Take 5 parts of organic carrier system and add 10 parts of epoxy resin E-44, after fully stirring evenly, add 85 parts of composite conductive filler, stir in a planetary mixer at 10r / min for 5 minutes, and vacuum at 25r / min Stir for 20 minutes, pause for 5 minutes and then stir for 10 minutes at 15 r / min. A copper-based composite conductive paste for thin film circuit boards is obtained.

[0039] (4...

Embodiment 2

[0041] (1) Take 8 parts of spherical copper powder of about 6 μm and 2 parts of SnAgCu alloy powder of about 3 μm and fully mix to obtain a composite conductive filler.

[0042] (2) Take 3.98 parts of triethanolamine as a curing agent, and sequentially add 0.2 parts of 2-ethyl-4 methylimidazole, 0.4 parts of 3-aminopropyltriethoxysilane, 2.5 parts of twelve to ten Tetraglycidyl ether, 1 part of tributyl phosphate, 0.42 part of ascorbic acid, 0.7 part of polyethylene glycol, and 0.8 part of NA acid anhydride are fully stirred to obtain an organic carrier system.

[0043] (3) Take 5 parts of organic carrier system and add 10 parts of epoxy resin E-44, after fully stirring evenly, add 85 parts of composite conductive filler, stir in a planetary mixer at 10r / min for 5 minutes, and vacuum at 25r / min Stir for 20 minutes, pause for 5 minutes and then stir for 10 minutes at 15 r / min. A copper-based composite conductive paste for thin film circuit boards is obtained.

[0044] (4) Aft...

Embodiment 3

[0046] (1) Take 6 parts of spherical copper powder of about 6μm and 4 parts of SnAgCu alloy powder of about 3um and fully mix to obtain a composite conductive filler

[0047] (2) Take 3.98 parts of triethanolamine as a curing agent, and sequentially add 0.2 parts of 2-ethyl-4 methylimidazole, 0.4 parts of 3-aminopropyltriethoxysilane, 2.5 parts of twelve to ten Tetraglycidyl ether, 1 part of tributyl phosphate, 0.42 part of ascorbic acid, 0.7 part of polyethylene glycol, and 0.8 part of NA acid anhydride are fully stirred to obtain an organic carrier system.

[0048] (3) Take 10 parts of organic carrier system and add 15 parts of epoxy resin E-44, after fully stirring evenly, add 75 parts of composite conductive filler, stir in a planetary mixer at 10r / min for 5 minutes, and vacuum at 25r / min Stir for 20 minutes, pause for 5 minutes and then stir for 10 minutes at 15 r / min. A copper-based composite conductive paste for thin film circuit boards is obtained.

[0049] (4) After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com