Gate structure, manufacturing method of gate structure, and enhanced semiconductor device

A gate structure and gate electrode technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as low turn-on voltage, insufficient hole concentration, uneven device turn-on voltage and on-resistance, etc. , to increase the turn-on voltage, improve uniformity and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

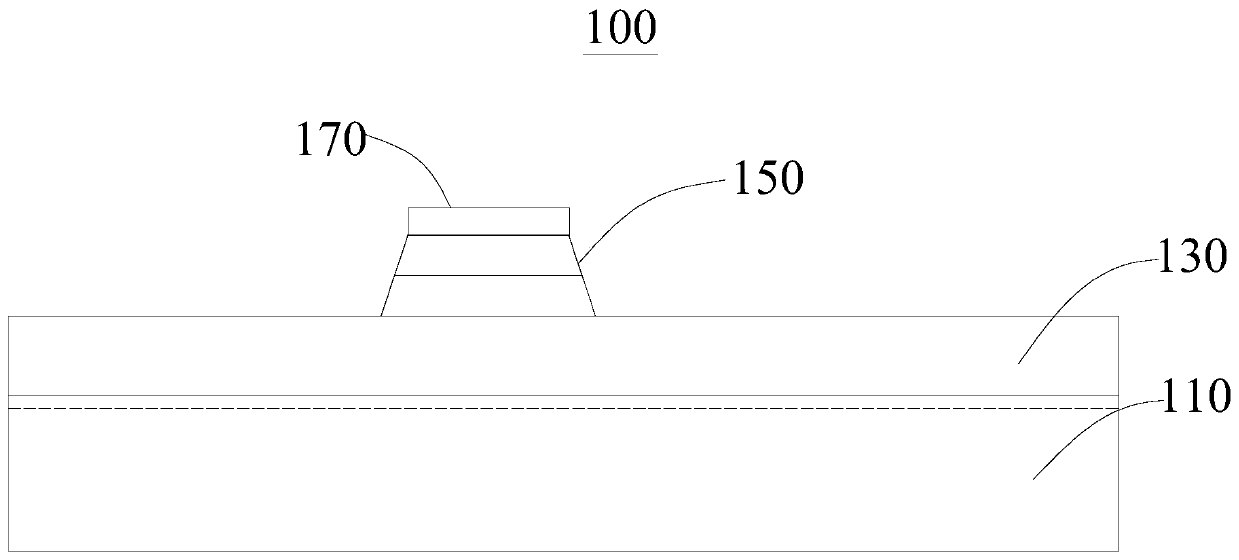

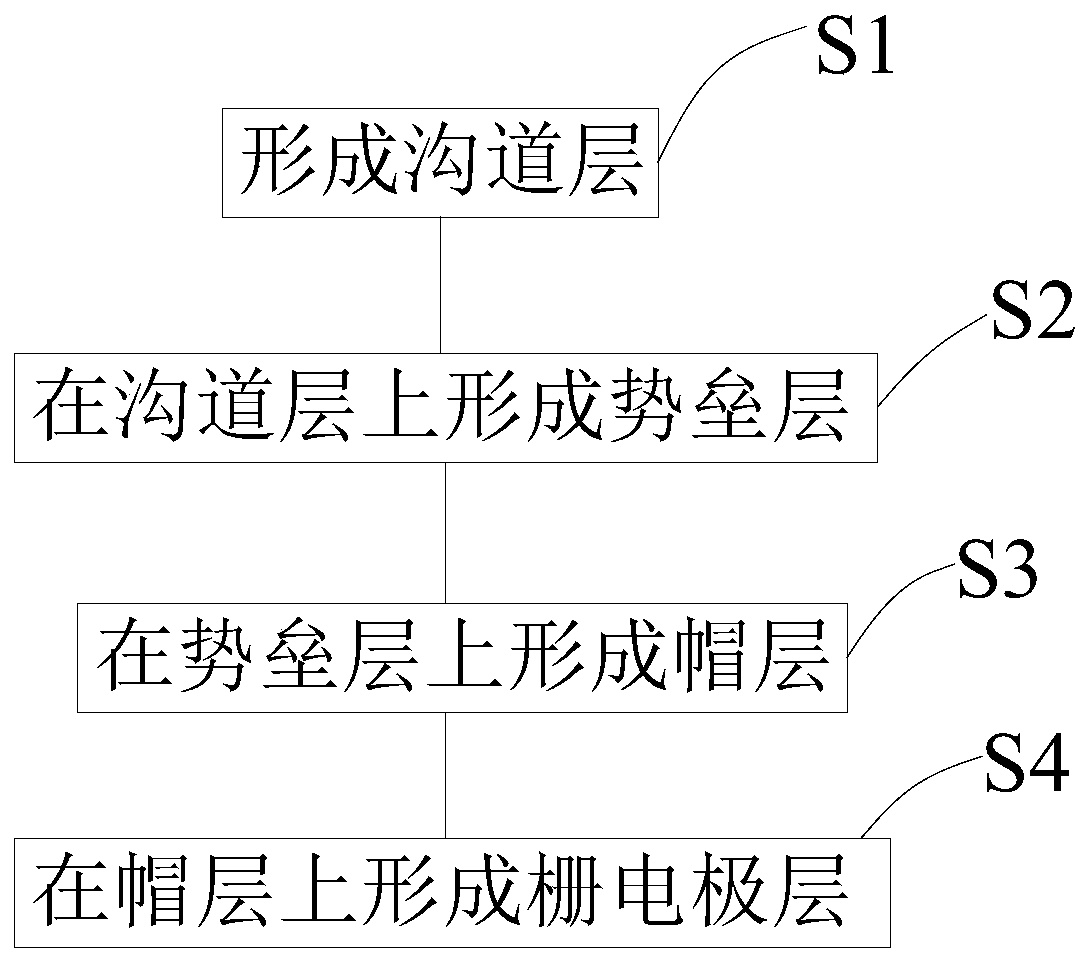

[0046] Please refer to figure 1 , this embodiment provides a gate structure 100 that can increase the turn-on voltage and improve the applicability of the overall device. The gate structure 100 is a part of the enhanced GaN HEMT device structure, and the enhanced GaN HEMT device also includes a support layer 200 , a source electrode and a drain electrode. For the specific structure of the enhanced GaN HEMT device, please refer to subsequent embodiments.

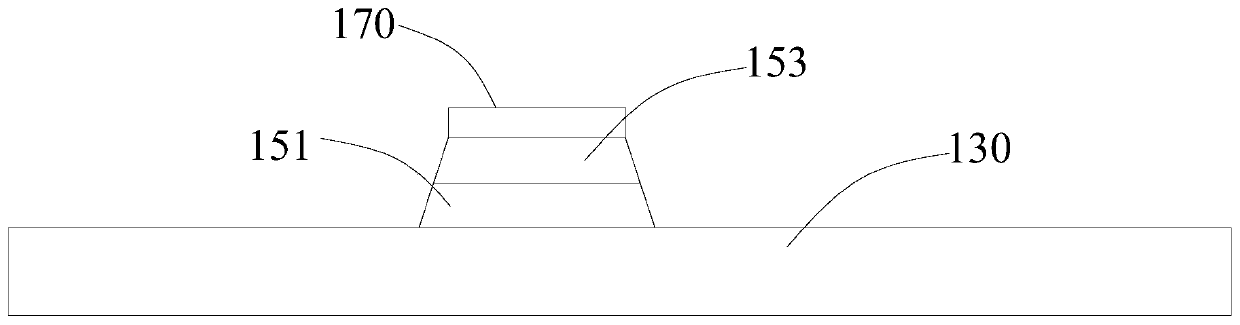

[0047] The gate structure 100 provided in this embodiment includes: a channel layer 110, a barrier layer 130 disposed on the channel layer 110, a cap layer 150 disposed on the barrier layer 130, and a gate electrode disposed on the cap layer 150 layer 170 , wherein the cap layer 150 has a crystal polarization orientation opposite to that of the barrier layer 130 . The channel layer 110 is used to be disposed on a substrate, and a passivation layer 500 is also disposed on the cap layer 150 and part of the barrier layer 130. F...

no. 2 example

[0070] see Figure 4 , this embodiment provides an enhanced semiconductor device 10, including a support layer 200, a gate structure 100, a source electrode layer 300, and a drain electrode layer 400, wherein the basic structure and principle of the gate structure 100 and the resulting technical effects and The first embodiment is the same, and for brief description, for parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0071] The gate structure 100 includes: a channel layer 110, a barrier layer 130 disposed on the channel layer 110, a cap layer 150 disposed on the barrier layer 130, and a gate electrode layer 170 disposed on the cap layer 150, wherein, The cap layer 150 has an opposite crystal polarization orientation to the barrier layer 130 . The channel layer 110 is disposed on the support layer 200 , and the source electrode layer 300 and the drain electrode layer 400 are both disposed on the barrier lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com