Preparation method and application of novel herbicide

A herbicide, a new type of technology, applied in the field of pesticide chemistry, can solve the problems of inability to achieve broad-spectrum control effects on weeds, short application period, and many residues, and achieve good controlled release ability, reduced usage, and extended release cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

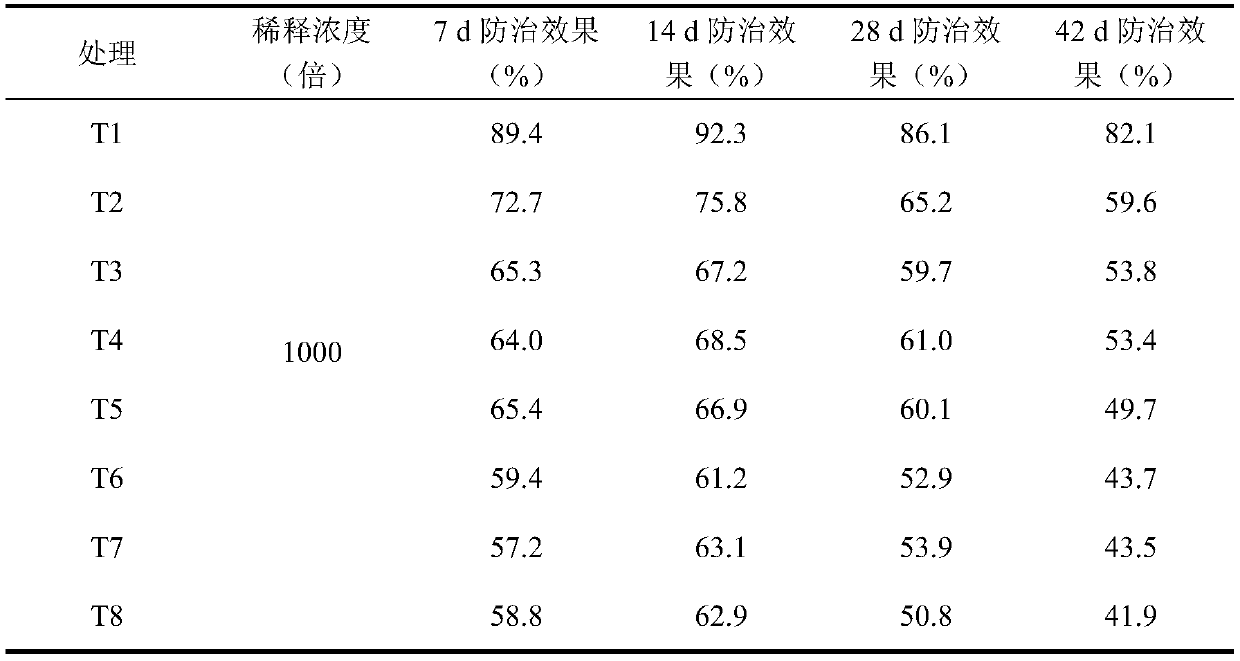

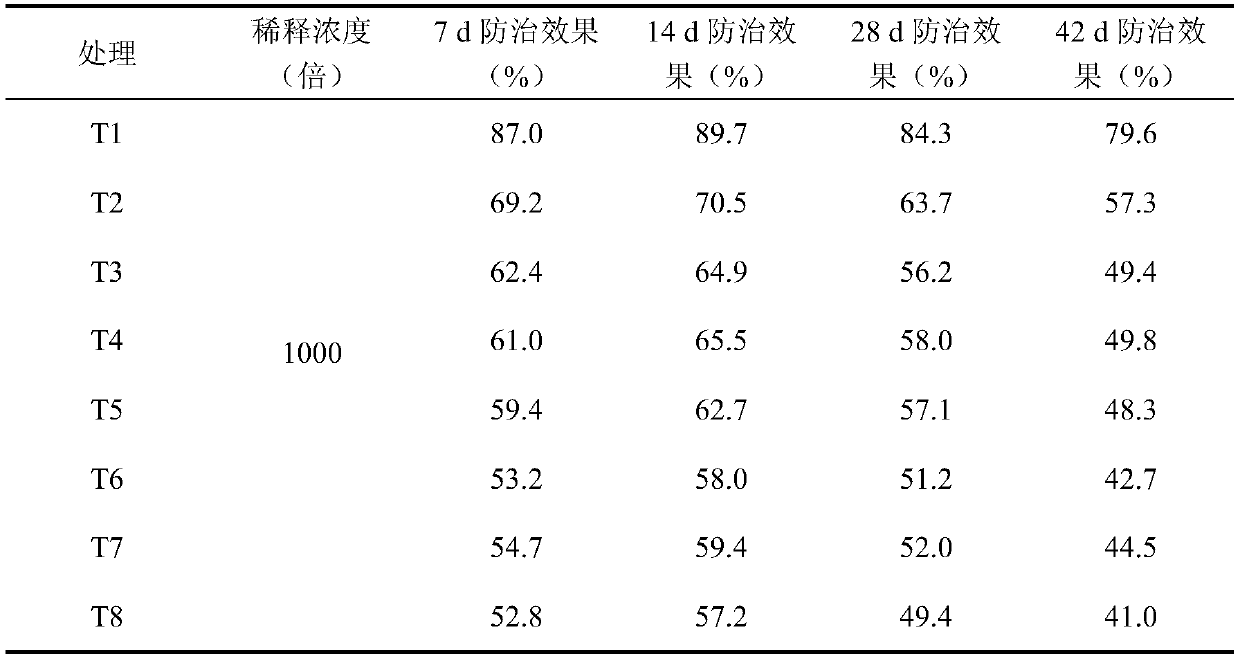

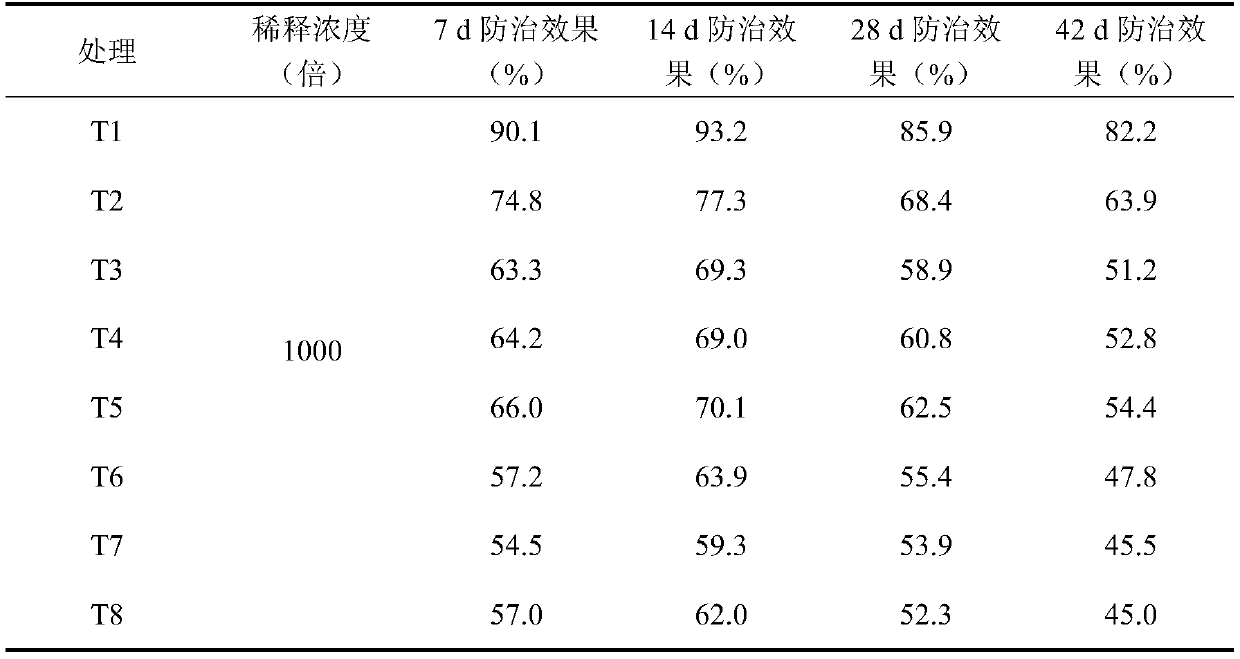

Examples

Embodiment 1

[0029] The preparation of the novel herbicide of embodiment 1 active ingredient 10%

[0030] 1) The gamma-polyglutamic acid used is the spray-dried powder of fermentation broth containing gamma-polyglutamic acid, which is prepared by spray-drying the fermentation broth containing gamma-polyglutamic acid, wherein the gamma-polyglutamic acid The content is 35wt%, and the molecular weight is 1000kDa.

[0031] 2) Get the raw materials (mass ratio) in the formula: 5% γ-polyglutamic acid, 4% quinclorac, 3% bispyribac, 3% glufosinate-ammonium, 8% organic silicon, Tween-60# 9%, gelatin 6%, lignosulfonate 5%, epoxy soybean oil 5%, water 52%.

[0032] 3) Add quinclorac, bispyribac, glufosinate-ammonium, Tween-60#, gelatin, lignosulfonate, epoxy soybean oil and water into the reaction kettle, control the temperature at 50°C, and stir at a constant speed for 30 minutes , standing still, the mixture was obtained.

[0033] 4) Add silicone surfactant to the mixture prepared in step 3), co...

Embodiment 2

[0034] The preparation of the novel herbicide of embodiment 2 active ingredient 30%

[0035] 1) The gamma-polyglutamic acid used is the spray-dried powder of fermentation broth containing gamma-polyglutamic acid, which is prepared by spray-drying the fermentation broth containing gamma-polyglutamic acid, wherein the gamma-polyglutamic acid The content is 35wt%, and the molecular weight is 1000kDa.

[0036] 2) Raw materials (mass ratio) in the obtained formula: 5% of γ-polyglutamic acid, 10% of quinclorac, 10% of bispyribac, 10% of glufosinate-ammonium, 8% of silicone, Tween-60# 9%, gelatin 6%, lignosulfonate 5%, epoxy soybean oil 5%, water 32%.

[0037] 3) Add the quinclorac, bisfluben, glufosinate, Tween-60#, gelatin, lignosulfonate, epoxy soybean oil and water prepared in step 2) into the reaction kettle, and control the temperature at 50 ℃, stirred at a constant speed for 30 min, and stood still to obtain a mixture.

[0038] 4) Add silicone surfactant to the mixture prep...

Embodiment 3

[0039] The preparation of the novel herbicide of embodiment 3 active ingredient 50%

[0040] 1) The gamma-polyglutamic acid used is the spray-dried powder of fermentation broth containing gamma-polyglutamic acid, which is prepared by spray-drying the fermentation broth containing gamma-polyglutamic acid, wherein the gamma-polyglutamic acid The content is 35wt%, and the molecular weight is 1000kDa.

[0041] 2) Raw materials (mass ratio) in the obtained formula: 5% γ-polyglutamic acid, 16% quinclorac, 18% bispyribac, 16% glufosinate-ammonium, 8% organic silicon, Tween-60# 9%, gelatin 6%, lignosulfonate 5%, epoxy soybean oil 5%, water 12%.

[0042] 3) Add the quinclorac, bisfluben, glufosinate, Tween-60#, gelatin, lignosulfonate, epoxy soybean oil and water prepared in step 2) into the reaction kettle, and control the temperature at 50 ℃, stirred at a constant speed for 30 min, and stood still to obtain a mixture.

[0043] 4) Add silicone surfactant to the mixture prepared in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com