Intelligent design method of concrete production matching ratio

A technology of intelligent design and mixing ratio, applied in the fields of mixed operation control, chemical instruments and methods, mixed operation control devices, etc., can solve the problems of low calculation efficiency, no reference to national standards, poor local optimal solutions, etc., to save production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

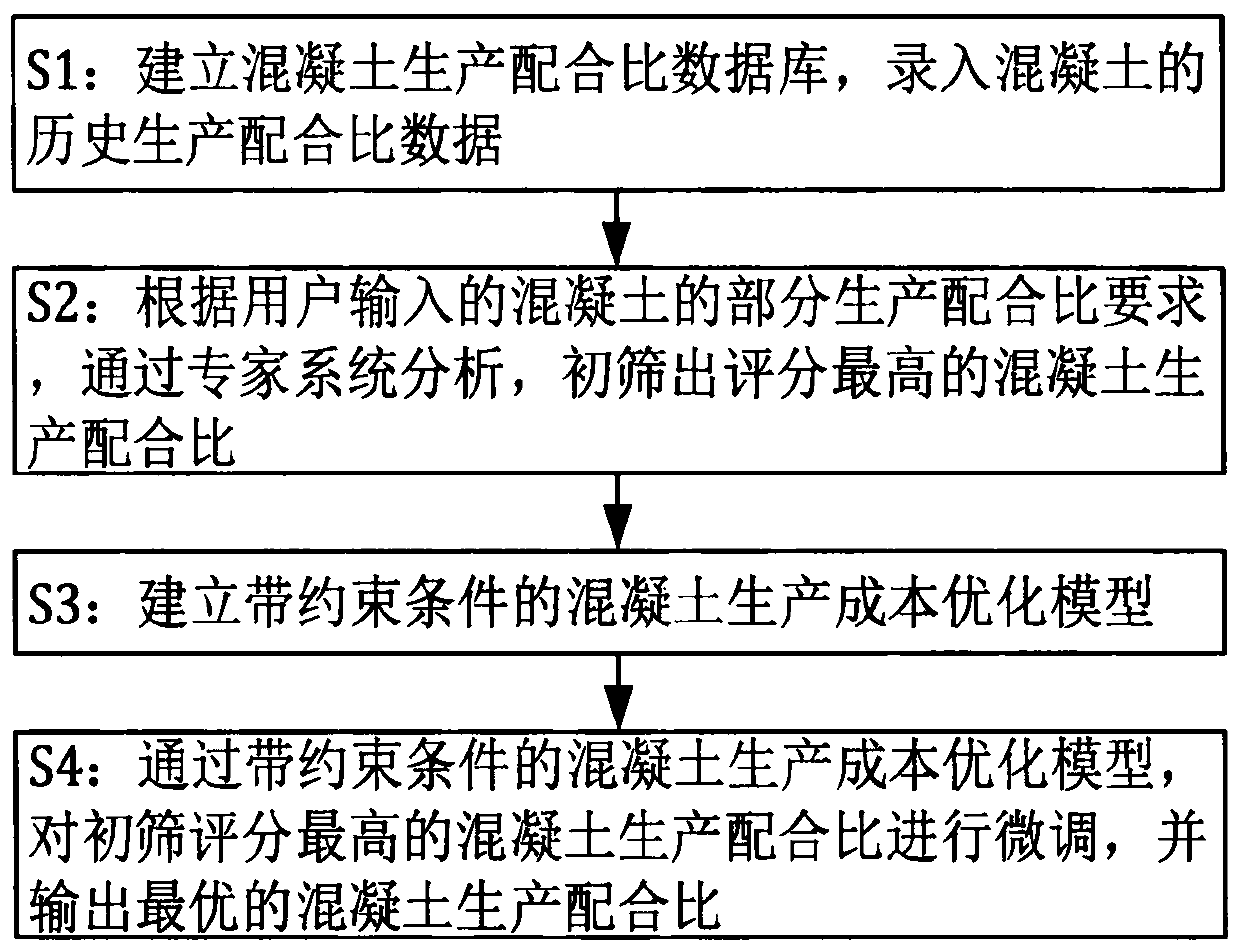

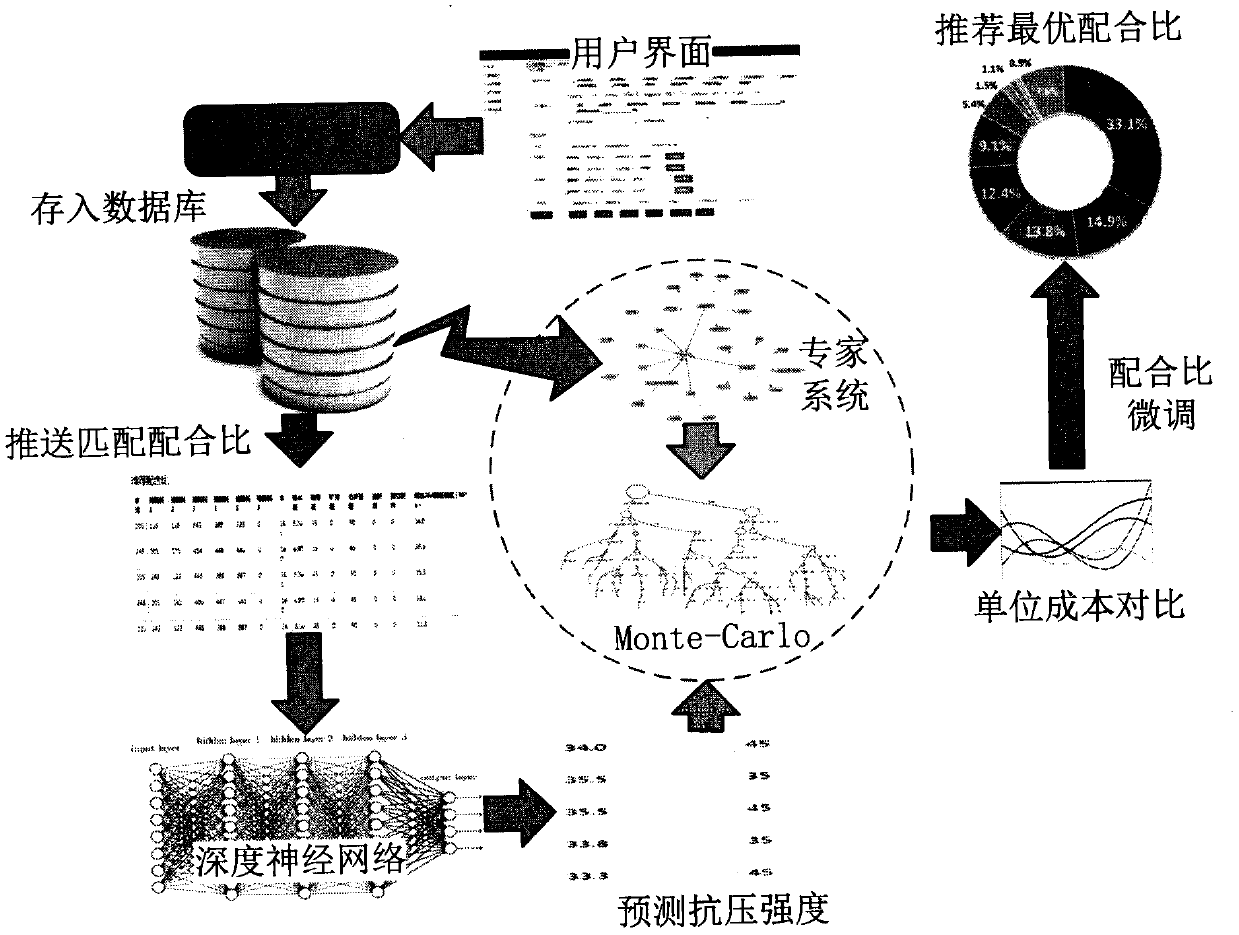

[0026] Example 1: For the 8437 pieces of historical concrete production mix data provided by a construction engineering group, computer intelligence is required to assist the user to adjust the parameters of a C20 concrete in July 2019 to meet the compressive strength requirements of the concrete, and at the same time To reduce production costs, this embodiment provides "an intelligent aided design method for concrete production mix ratio", combining figure 2 ,details as follows:

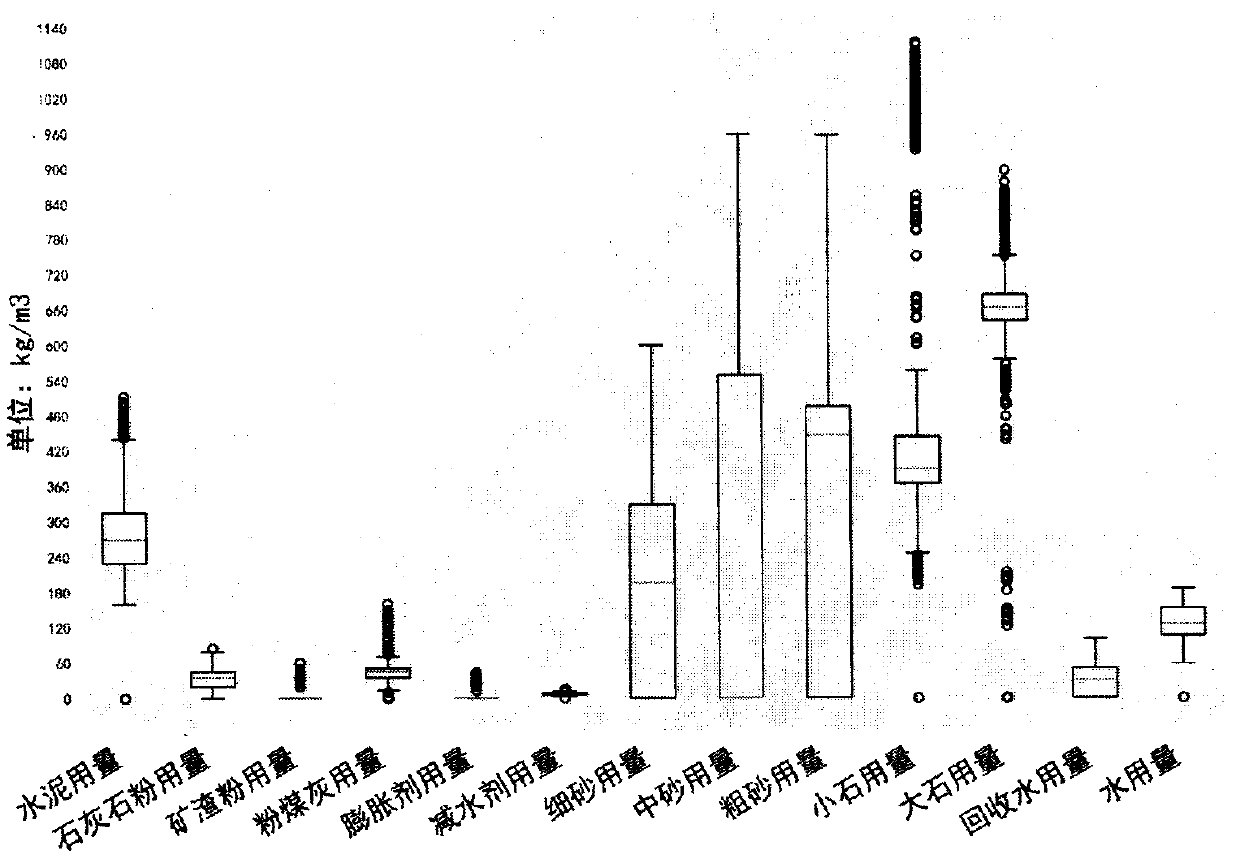

[0027] Step 1: Create a concrete production mix ratio database for the construction engineering group, and enter 8437 pieces of historical concrete production mix ratio data. The database includes three types of parameters: necessary production mix ratio parameters, optional production mix ratio parameters, and system-generated production mix ratio parameters. Among them, the necessary production mix ratio parameters include: concrete type, strength grade, slump, and expansion. The remaining 11 pa...

Embodiment 2

[0042] Example 2: According to the 8437 pieces of historical concrete production mix ratio data provided by a construction engineering group, the user requires the system to automatically recommend C25, C30, C35 and other concrete production mix ratios in July 2019. This example provides "a Intelligent Active Design Methodology for Mix Proportions in Concrete Production”, combined with figure 2 ,details as follows:

[0043] Step 1: Create a concrete production mix ratio database for the construction engineering group, and enter 8437 pieces of historical concrete production mix ratio data.

[0044] Step 2: The system randomly selects the production mix ratios of C25, C30, and C35 concrete from the database as user requirements, and screens out the necessary production mix ratio parameters from the concrete production mix ratio database that are completely consistent and the production date is between May and September Concrete production mix ratio data during the monthly peri...

Embodiment 3

[0049] Example 3: For the concrete historical production mix ratio data provided by an organization in the construction industry, the user needs computer intelligence to assist the user to adjust the parameters of a C20 concrete in July 2019. This example provides "a concrete production mix ratio cloud intelligent aided design method", combined with Figure 5 ,details as follows:

[0050] Step 1: Establish a concrete production mix ratio cloud database, and enter the historical concrete production mix ratio data of all companies in the construction organization.

[0051] Step 2: Part of the production mix ratio requirements of concrete input by a user of a company, after the information is sent to the local database server, initiates Qingqiu to the cloud database server, and screens out the necessary production mix ratio parameters from the concrete production mix ratio cloud database. The system generates concrete production mix ratio data with similar production mix ratio p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com