Synthesis method of polyether polyol for water swelled polyurethane waterproof elastomer

A polyether polyol and polyurethane waterproof technology is applied in the field of polyether polyol to achieve the effects of good water absorption, good structural mechanical and structural properties, and improved market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

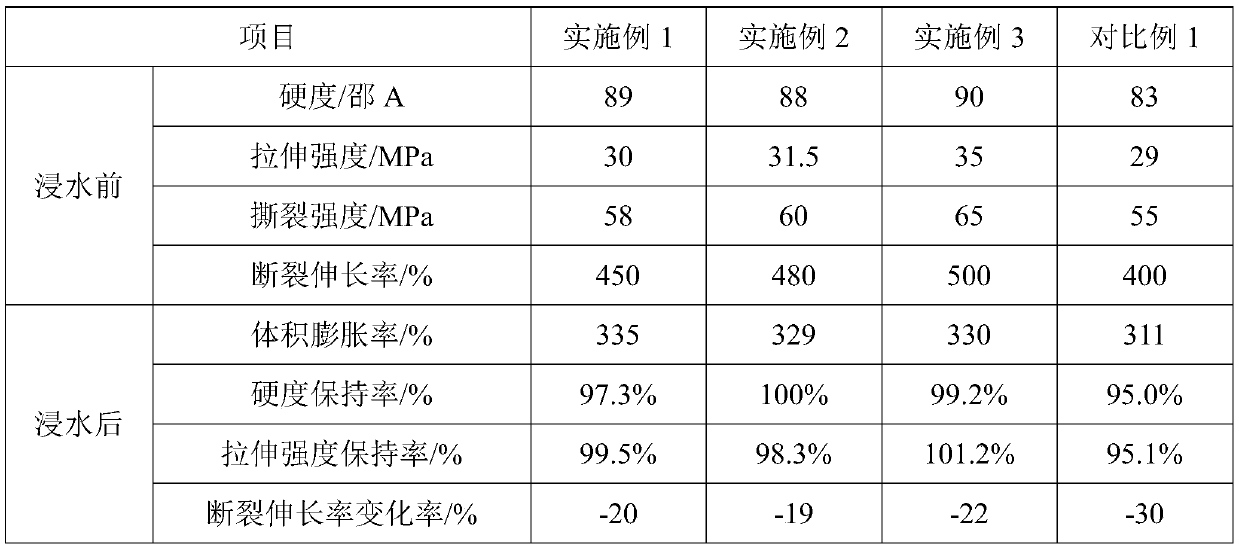

Examples

Embodiment 1

[0027] (1) Put 40g of ethylene glycol, 35g of palm oil, and 0.61g of KOH into a 5L reactor at room temperature, replace with nitrogen three times, heat up to 90°C, add 230g of ethylene oxide to the reactor, and heat up to 110°C, react under 0.15MPa pressure, stirring speed is 260r / min, polymerize for 5h, then remove monomer under vacuum condition for 1h, cool down to 80°C, add phosphoric acid for neutralization, then add magnesium silicate for adsorption, Finally, vacuum dehydration at 110° C. for 2 hours, and filtration to obtain the intermediate polyether polyol DX-1; its hydroxyl value was tested to be 260 mgKOH / g.

[0028] (2) Put 100g of intermediate polyether polyol DX-1, 300g of sucrose, and 20.8g of KOH into a 20L reactor, replace with nitrogen three times, heat up to 60°C, and pre-drop into the reactor at a stirring speed of 220r / min Propylene oxide, after the pre-dropping is successful, add the remaining propylene oxide. The total amount of propylene oxide added is 1...

Embodiment 2

[0030] (1) Put 40g of propylene glycol, 25g of linseed oil, and 0.45g of KOH into a 5L reaction kettle at room temperature, replace with nitrogen three times, heat up to 95°C, add 115g of ethylene oxide into the reaction kettle, and raise the temperature to 120°C after adding , react under the pressure of 0.25MPa, the stirring speed is 280r / min, continue to mature for 6 hours after the polymerization reaction, then remove the monomer under vacuum for 1 hour, cool down to 80°C, add phosphoric acid for neutralization, and then add magnesium silicate Carry out adsorption, and finally vacuum dehydrate at 110°C for 2 hours, and filter to obtain the intermediate polyether polyol DX-2; its hydroxyl value is 350 mgKOH / g.

[0031] (2) Put 100g of intermediate polyether polyol DX-2, 300g of sorbitol, and 30.7g of KOH into a 20L reactor, replace with nitrogen three times, raise the temperature to 70°C, and preheat the Drop propylene oxide, and add the remaining propylene oxide after the ...

Embodiment 3

[0033] (1) Put 40g of ethylene glycol, 10g of castor oil, and 1.17g of sodium bicarbonate into a 5L reactor at room temperature, replace with nitrogen three times, raise the temperature to 100°C, add 340g of ethylene oxide into the reactor, and finish adding Then heat up to 130°C, react under the pressure of 0.15MPa, the stirring speed is 300r / min, continue aging for 4 hours after the polymerization reaction is completed, then remove the monomer under vacuum condition for 1h, cool down to 80°C, add phosphoric acid for neutralization, Magnesium silicate was then added for adsorption, and finally dehydrated in vacuum at 110°C for 2 hours, filtered to obtain the intermediate polyether polyol DX-3; its hydroxyl value was tested to be 190 mgKOH / g.

[0034] (2) Put 100g of intermediate polyether polyol DX-3, 500g of sucrose, and 36.9g of sodium bicarbonate into a 20L reaction kettle, replace with nitrogen for 3 times, heat up to 80°C, and pour into the reaction kettle at a stirring s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com