Antibacterial anti-ultraviolet-ray melamine impregnated paper and preparation method thereof

An anti-ultraviolet and melamine technology, applied in special paper, paper, papermaking and other directions, can solve the problems of easy chemical reaction, water-based ink fading, photoaging reaction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

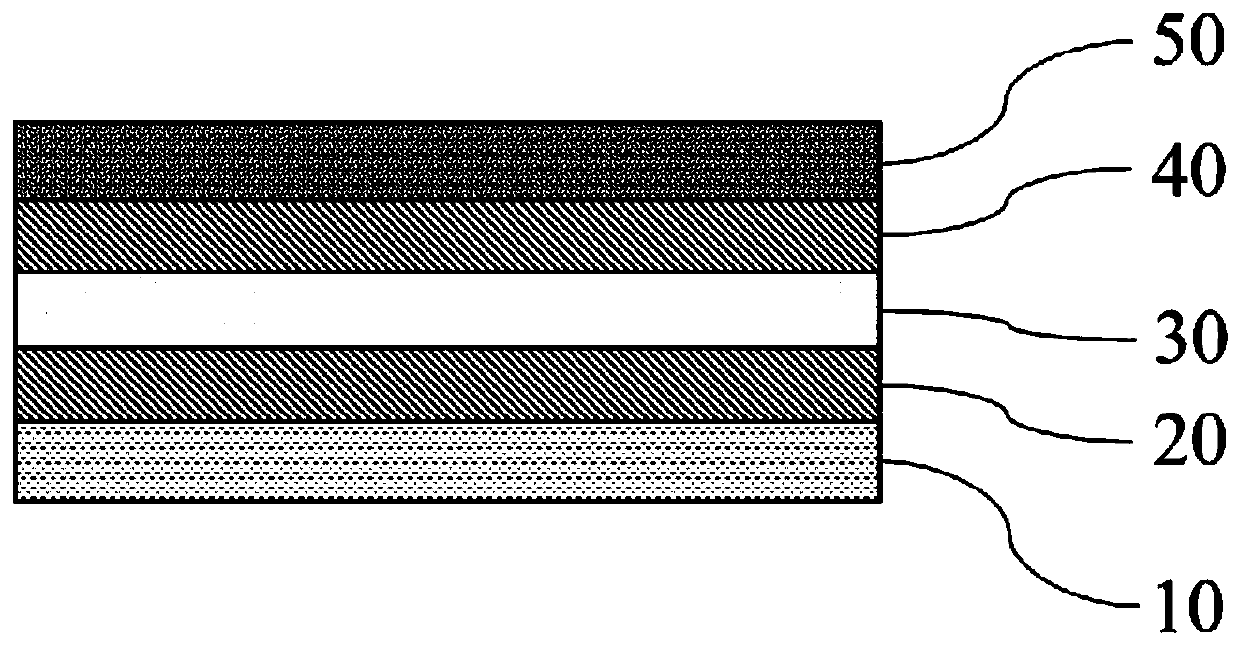

[0048] A kind of antibacterial and anti-ultraviolet melamine impregnated paper (structural schematic diagram as figure 1 shown), including a melamine resin layer (thickness 150 μm), a first UV-resistant urea-formaldehyde resin layer (thickness 200 μm), printed decorative paper (gram weight 80 g / m) arranged in sequence from bottom to top 2 ), a second anti-ultraviolet urea-formaldehyde resin layer (thickness 200 μm) and an antibacterial and anti-ultraviolet melamine resin layer (thickness 180 μm).

[0049] The preparation method of the above-mentioned antibacterial and anti-ultraviolet melamine impregnated paper comprises the following steps:

[0050] 1) Add 350 parts by mass of formaldehyde solution (mass fraction 37%), 90 parts by mass of urea and 3 parts by mass of urotropine into the reactor, heat up to 90°C for 30 minutes, and then keep it at 90-95°C for 60 minutes to test the resin Whether there is an atomization point in water at 10°C, until the atomization point is tes...

Embodiment 2

[0063] A kind of antibacterial and anti-ultraviolet melamine impregnated paper (structural schematic diagram as figure 1 shown), including a melamine resin layer (thickness 150 μm), a first UV-resistant urea-formaldehyde resin layer (thickness 240 μm), printed decorative paper (gram weight 90 g / m) arranged in sequence from bottom to top 2 ), a second anti-ultraviolet urea-formaldehyde resin layer (thickness 240 μm) and an antibacterial and anti-ultraviolet melamine resin layer (thickness 200 μm).

[0064] The preparation method of the above-mentioned antibacterial and anti-ultraviolet melamine impregnated paper comprises the following steps:

[0065] 1) Add 350 parts by mass of formaldehyde solution (mass fraction 37%), 90 parts by mass of urea and 3 parts by mass of urotropine into the reaction kettle, heat up to 90°C for 30 minutes, then keep warm at 90-95°C for 60 minutes, and test the resin Whether there is an atomization point in water at 10°C, until the atomization poin...

Embodiment 3

[0074] A kind of antibacterial and anti-ultraviolet melamine impregnated paper (structural schematic diagram as figure 1 shown), including a melamine resin layer (thickness 160 μm), a first UV-resistant urea-formaldehyde resin layer (thickness 270 μm), printed decorative paper (gram weight 100 g / m) arranged in sequence from bottom to top 2 ), a second anti-ultraviolet urea-formaldehyde resin layer (thickness 270 μm) and an antibacterial and anti-ultraviolet melamine resin layer (thickness 190 μm).

[0075] The preparation method of the above-mentioned antibacterial and anti-ultraviolet melamine impregnated paper comprises the following steps:

[0076] 1) Add 350 parts by mass of formaldehyde solution (mass fraction 37%), 90 parts by mass of urea and 3 parts by mass of urotropine into the reaction kettle, heat up to 90°C for 30 minutes, then keep warm at 90-95°C for 60 minutes, and test the resin Whether there is an atomization point in water at 10°C, until the atomization poi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com