Preparation method of solid imprinted polymer modified QCM-D sensor

A technology for imprinting polymers and sensors, which is applied in the field of preparation of QCM-D sensors to achieve the effect of improving selectivity and specificity and simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a solid-phase imprinted polymer-modified QCM-D sensor, using tetracycline as a target molecule, first immobilizing tetracycline on magnetic ferric oxide particles prepared in the laboratory, and then using the solid-phase matrix as a template molecule , mixed with functional monomers, cross-linking agents, and initiators to prepare a solid-phase imprinted polymer, and modify it onto the surface of a QCM-D chip to obtain a QCM-D sensor modified by a solid-phase imprinted polymer, which specifically includes the following steps:

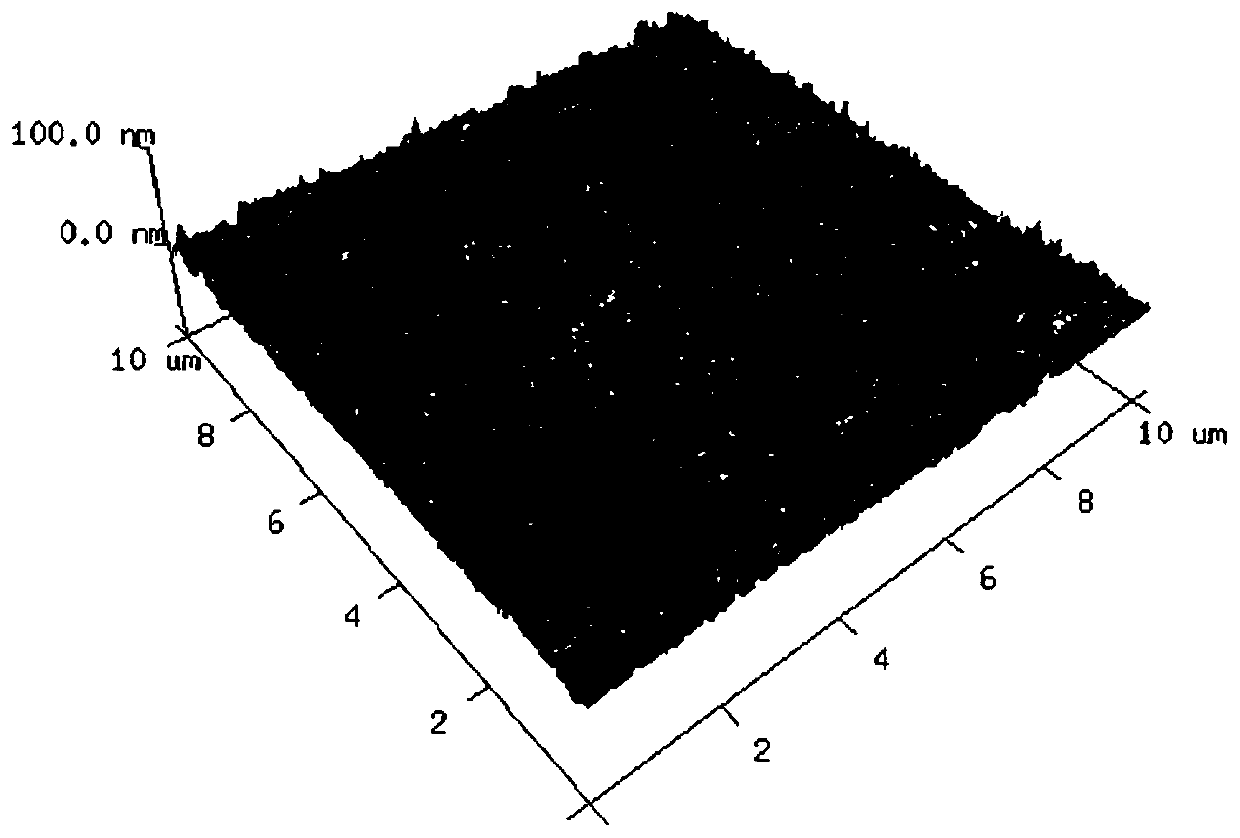

[0029] 1) Preparation of solid phase matrix: the solid phase matrix used in the present invention is silicon dioxide modified ferric oxide particles. Among them, iron ferric oxide is prepared by the polyol method, and the specific preparation method is as follows: 1.3g of ferric chloride hexahydrate is dissolved in 40mL of ethylene glycol, and after ultrasonic dispersion, 3.2g of anhydrous sodium acetate and 2.0g of polyet...

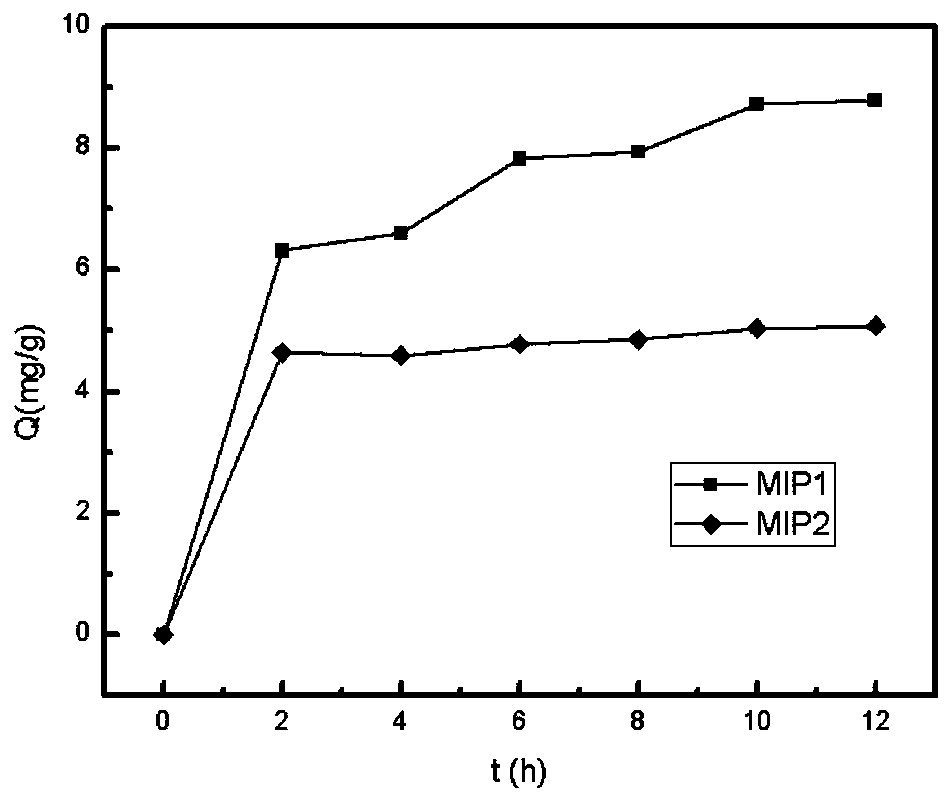

Embodiment 2

[0038] A method for preparing a solid-phase imprinted polymer-modified QCM-D sensor, using tetracycline as a target molecule, first immobilizing tetracycline on magnetic ferric oxide particles prepared in the laboratory, and then using the solid-phase matrix as a template molecule , mixed with functional monomers, cross-linking agents, and initiators to prepare a solid-phase imprinted polymer, and modify it onto the surface of a QCM-D chip to obtain a QCM-D sensor modified by a solid-phase imprinted polymer, which specifically includes the following steps:

[0039] 1) Preparation of solid phase matrix: the solid phase matrix used in the present invention is silicon dioxide modified ferric oxide particles. Among them, ferric ferric oxide is prepared by polyol method, and then it is modified with silicon dioxide by tetraethyl orthosilicate to obtain ferric ferric oxide particles modified with silicon dioxide. The specific preparation method is the same as that in Example 1.

[0...

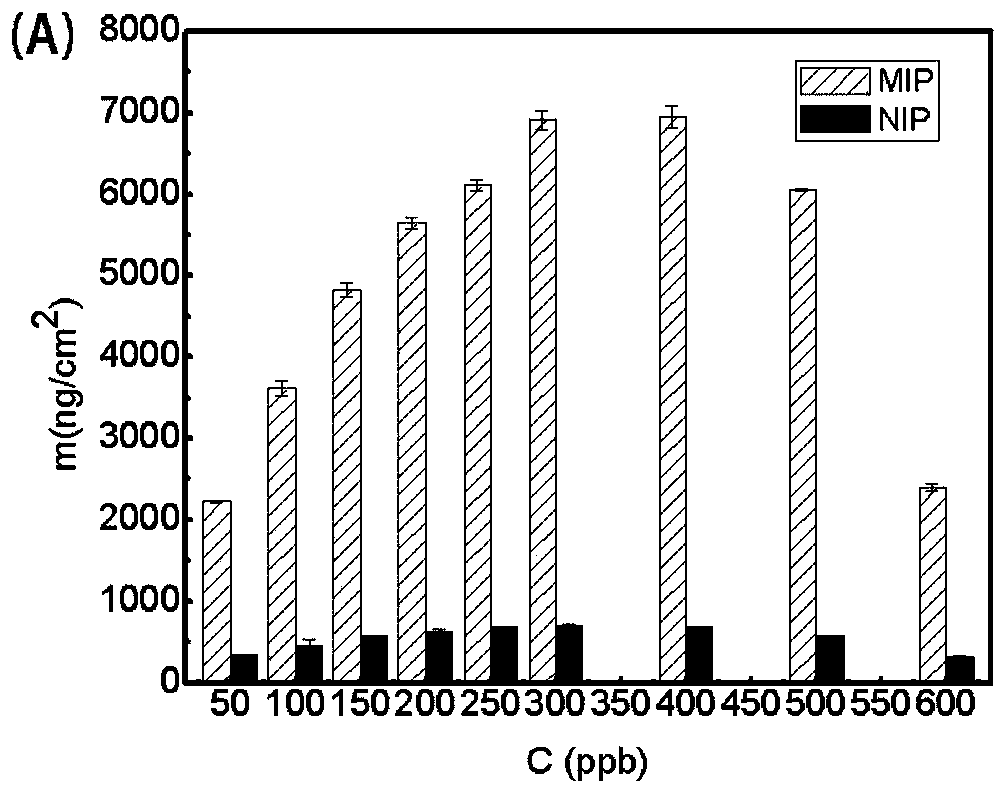

Embodiment 3

[0044] A method for preparing a solid-phase imprinted polymer-modified QCM-D sensor, using tetracycline as a target molecule, first immobilizing tetracycline on magnetic ferric oxide particles prepared in the laboratory, and then using the solid-phase matrix as a template molecule , mixed with functional monomers, cross-linking agents, and initiators to prepare a solid-phase imprinted polymer, and modify it onto the surface of a QCM-D chip to obtain a QCM-D sensor modified by a solid-phase imprinted polymer, which specifically includes the following steps:

[0045] 1) Preparation of solid phase matrix: the solid phase matrix used in the present invention is silicon dioxide modified ferric oxide particles. Among them, ferric ferric oxide is prepared by polyol method, and then it is modified with silicon dioxide by tetraethyl orthosilicate to obtain ferric ferric oxide particles modified with silicon dioxide. The specific preparation method is the same as that in Example 1.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com