High-voltage cabinet with a long service life

A high-pressure cabinet, life-span technology, applied in gas treatment, membrane technology, other chemical processes, etc., can solve the problems of poor drying effect of high-pressure cabinets, difficult to meet the needs of high standards, etc., to solve the problems of poor drying effect and addition process Convenience and simplicity, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

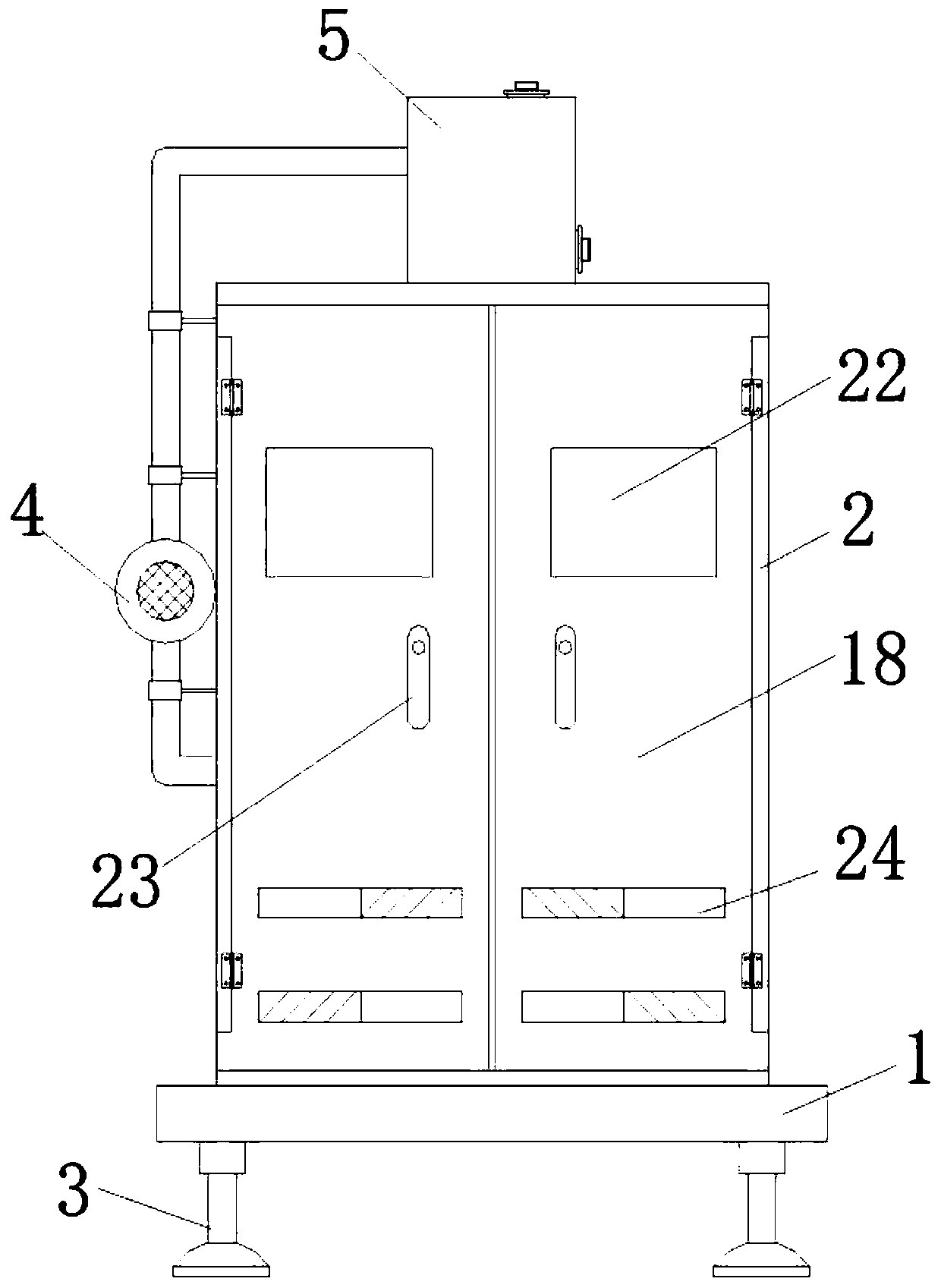

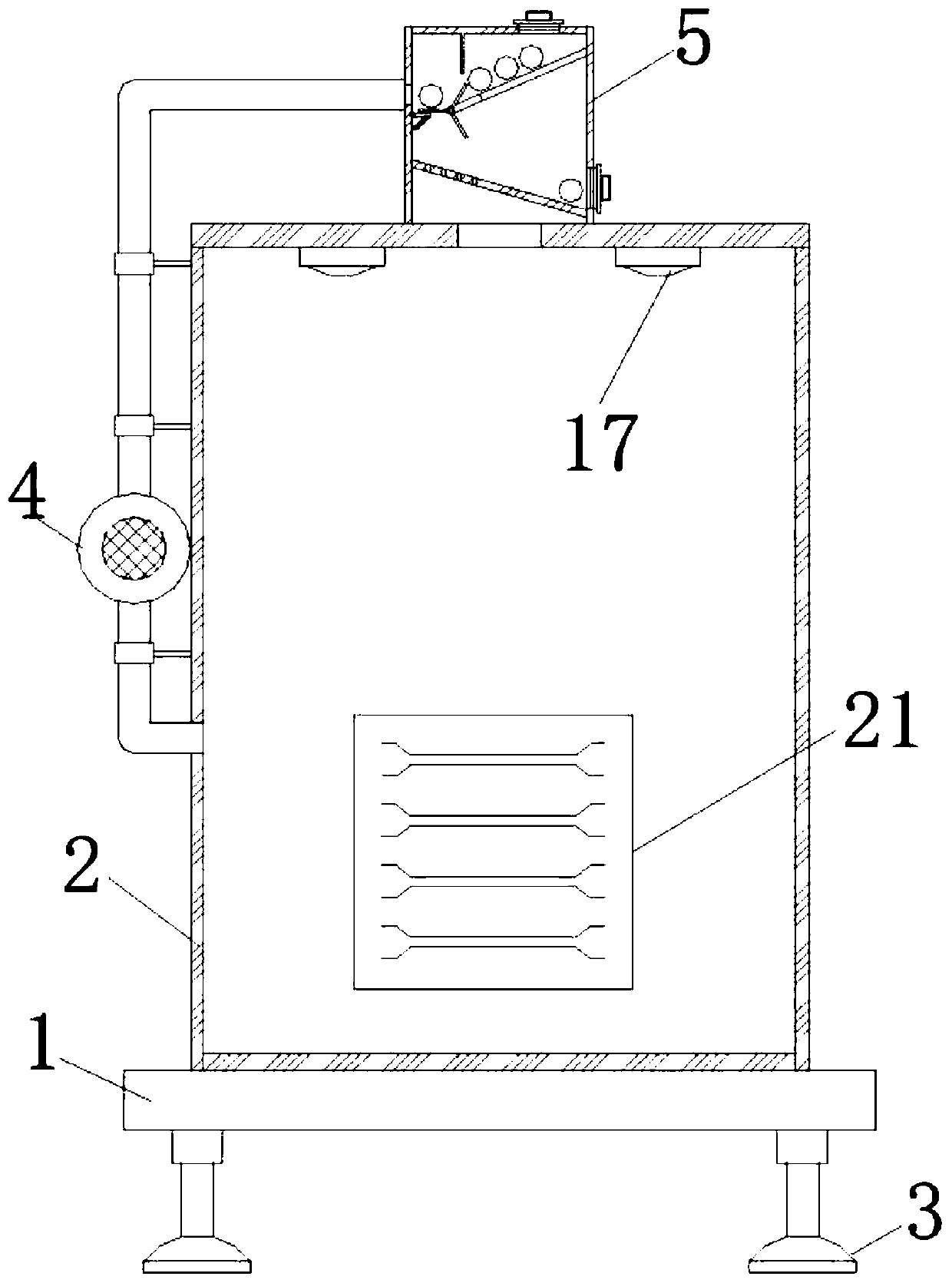

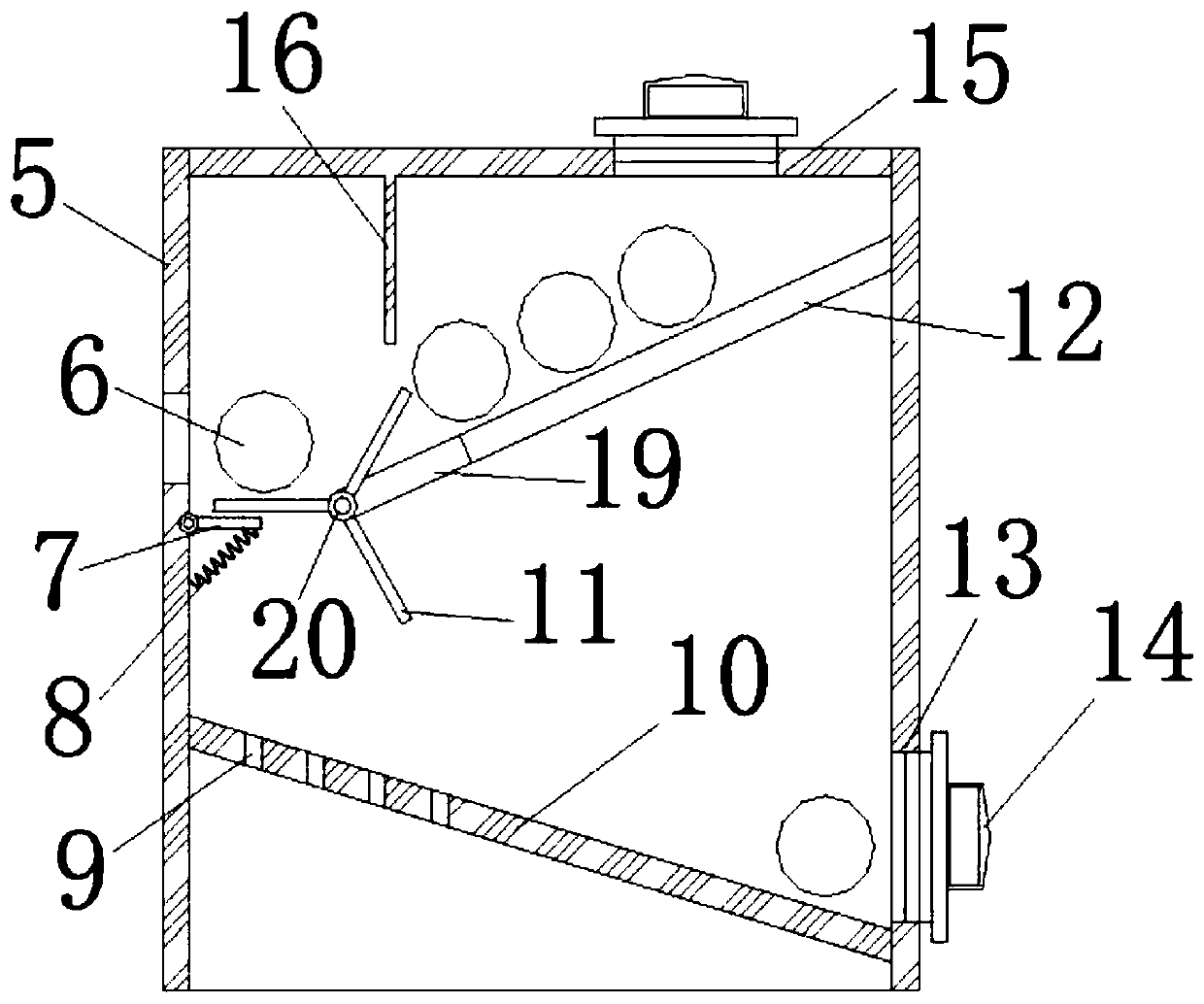

[0023] refer to Figure 1-3 , a high-voltage cabinet with high service life, including a base 1, a leg 3 is installed on the bottom of the base 1, a high-voltage cabinet 2 is installed on the top of the base 1, the high-voltage cabinet 2 is made of stainless steel, and the outside of the high-voltage cabinet 2 is painted with waterproof coating One side of the high-voltage cabinet 2 is hinged and connected with two inspection doors 18, a rotating handle 23 is installed in the middle of the inspection door, a visible window 22 is arranged above the inspection door 18, and warning stripes 24 are pasted on the bottom of the inspection door 18. 2. A lighting lamp 17 is installed on the top of the interior. A cooling plate 21 is installed at the bottom of the side away from the inspection door 18 inside the high-voltage cabinet 2. The middle part of one side of the high-voltage cabinet 2 is connected to the air inlet of the fan 4 through a pipe, and the air supply port of the fan 4 ...

Embodiment 2

[0031] The preparation method of desiccant 6 is as follows:

[0032] Mix the modified attapulgite clay and acrylic acid, stir under nitrogen protection, then add potassium persulfate and N,N-methylene bisacrylamide ammonium, react for a period of time, wash with water and extract acrylic acid and its homopolymer with acetone , after drying and crushing, the desiccant is obtained; wherein, the dosage of modified attapulgite clay: acrylic acid: potassium persulfate: N, N-methylenebisacrylamide is 60g: 600ml: 3g: 5g.

[0033] Wherein, the stirring time is 1.5 h in nitrogen protection, the reaction temperature is 60° C., and the reaction time is 2 h.

[0034] Wherein, the preparation method of the modified attapulgite clay is as follows:

[0035]Weigh attapulgite clay, add hexadecyl bromide and polydimethyldiallylammonium chloride, shake at room temperature, wash after high-speed centrifugation, activate for a period of time, and grind to obtain modified Attapulgite clay; wherei...

Embodiment 3

[0038] The preparation method of described desiccant 6 is as follows:

[0039] Mix the modified attapulgite clay and acrylic acid, stir under nitrogen protection, then add potassium persulfate and N,N-methylene bisacrylamide ammonium, react for a period of time, wash with water and extract acrylic acid and its homopolymer with acetone , after drying and crushing, the desiccant is obtained; wherein, the dosage of modified attapulgite clay: acrylic acid: potassium persulfate: N, N-methylenebisacrylamide is 60g: 600ml: 3g: 5g.

[0040] Wherein, the stirring time is 2 h under nitrogen protection, the reaction temperature is 60° C., and the reaction time is 2.5 h.

[0041] Wherein, the preparation method of the modified attapulgite clay is as follows:

[0042] Weigh attapulgite clay, add hexadecyl bromide and polydimethyldiallylammonium chloride, shake at room temperature, wash after high-speed centrifugation, activate for a period of time, and grind to obtain modified Attapulgit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com