Method for preparing two-dimensional layered nanometer material

A two-dimensional layered nano and two-dimensional material technology, applied in nano-carbon, chemical instruments and methods, molybdenum sulfide, etc., can solve the problems of long experiment time, dangerous cost, low efficiency, etc., to reduce energy consumption and reduce emissions , The effect of preparation method and steps is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

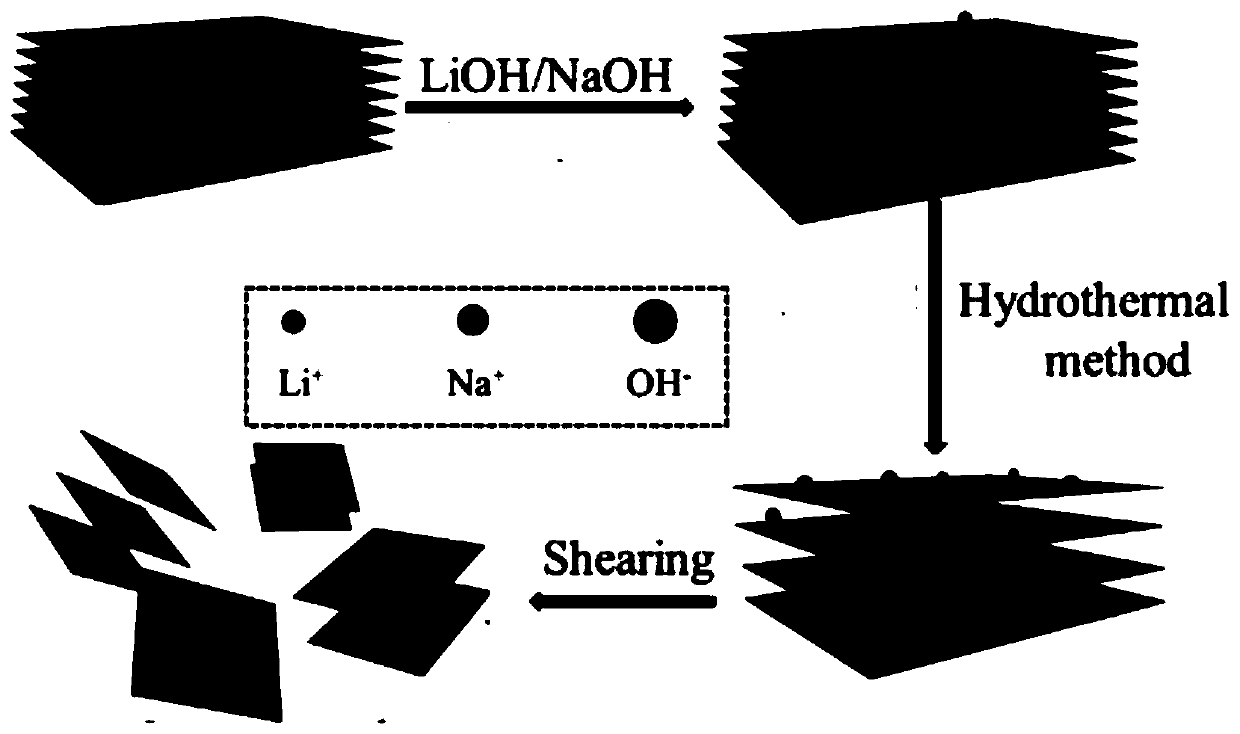

[0027] Disperse 0.38g LiOH and 0.61g NaOH in 60mL deionized water until completely dissolved, and disperse 0.51g block molybdenum disulfide in the transparent solution with magnetic stirring for 2h. Next, the suspension was transferred to a 100 mL autoclave reaction and maintained at 220 °C for 6 h at a speed of 10 rpm. The suspension solution containing molybdenum disulfide was added to a wall breaker with double four-leaf rotating blades, and the rotating blades were sheared 5 times at a speed of 18000 rpm (each sheared for 2 minutes and intermittently for 15 minutes) to obtain nanosheets.

[0028] Application: Weigh 16mg of the above MoS 2 The nanosheets are evenly dispersed in the 500SN base oil, and the friction coefficient is found to be 35.13% lower than that of the base oil through tribological tests.

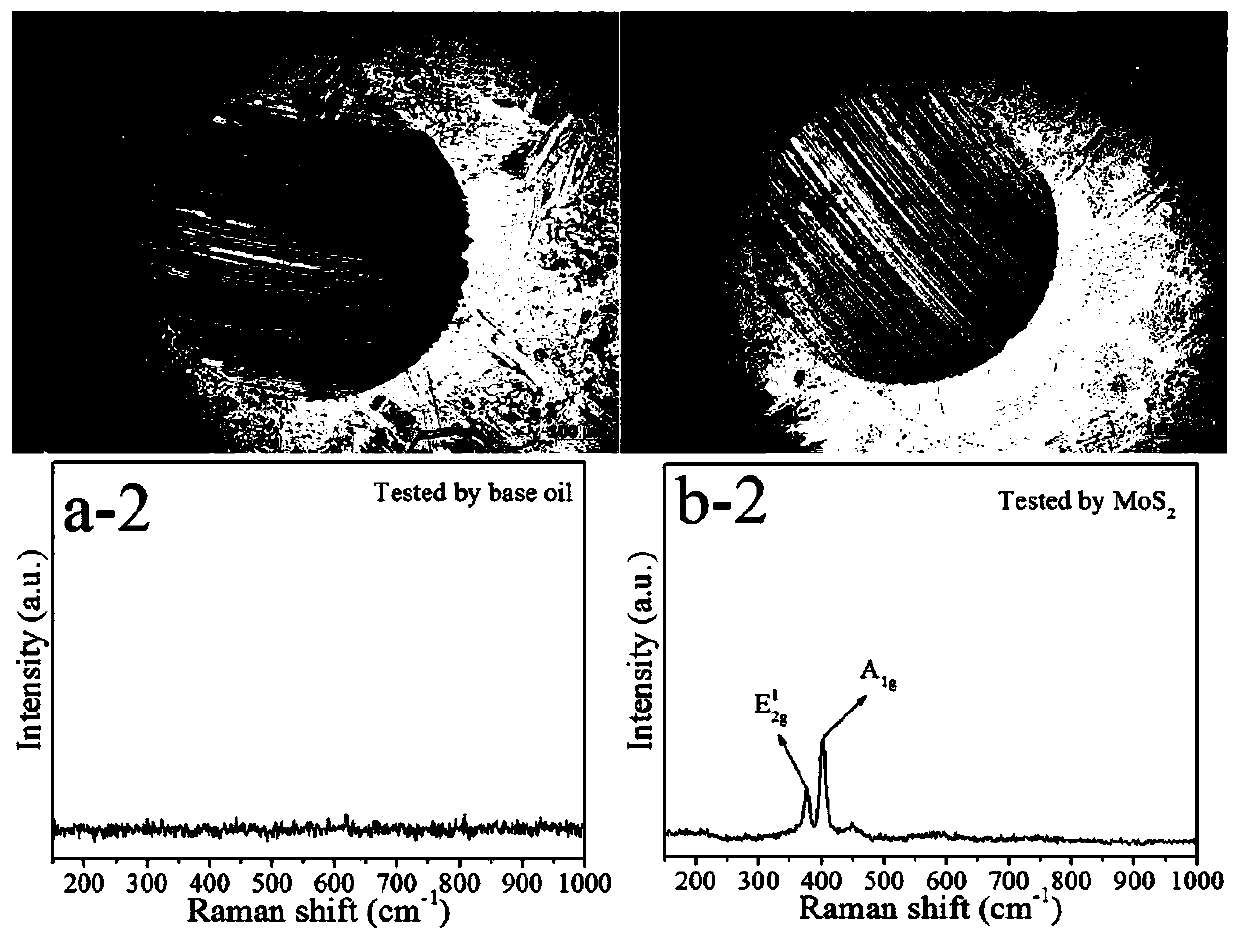

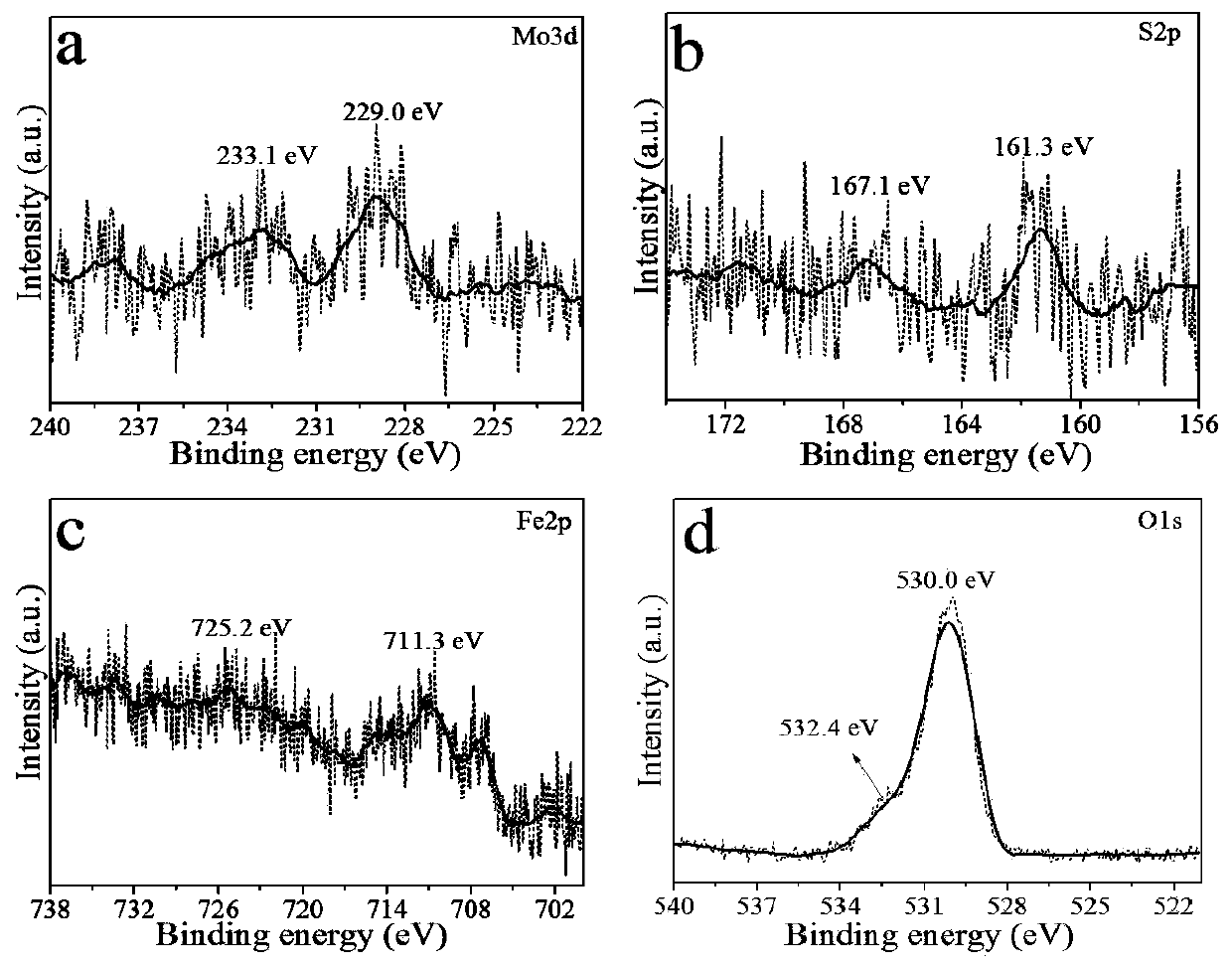

[0029] from figure 2 As can be seen in , the steel surface worn by the base oil has fairly rough marks, wide and deep grooves. Instead, the MoS 2 Added to the base...

Embodiment 2

[0032] Disperse 0.38g LiOH and 0.32g NaOH in 60mL deionized water until completely dissolved, and disperse 0.52g block graphite in the transparent solution with magnetic stirring for 2h. Next, the suspension was transferred to a 100 mL autoclave reaction and maintained at 220 °C for 6 h at a speed of 10 rpm. The graphite-containing suspension solution was added to a wall breaker with double four-leaf rotating blades, and the rotating blades were sheared 5 times at a speed of 18,000 rpm (each sheared for 2 minutes with an interval of 15 minutes) to obtain nanosheets.

[0033] Application: Weigh 16mg of the above-mentioned graphene and evenly disperse it in 100SN base oil. After tribological tests, it is found that the friction coefficient has decreased by 30.83% compared with the base oil.

Embodiment 3

[0035]Disperse 0.25g LiOH and 0.61g NaOH in 60mL deionized water until completely dissolved, and disperse 0.49g block boron nitride in the transparent solution with magnetic stirring for 2h. Next, the suspension was transferred to a 100 mL autoclave reaction and maintained at 220 °C for 6 h at a speed of 10 rpm. Add the boron nitride-containing suspension solution into a wall breaking machine with double four-leaf rotating blades, and the rotating blades shear 5 times at a speed of 18,000 rpm (each shearing is 2 minutes with an interval of 15 minutes) to obtain nanosheets.

[0036] Application: Weigh 16 mg of the above-mentioned boron nitride nanosheets and evenly disperse them in 150SN base oil. Tribological tests show that the friction coefficient has decreased by 32.12% compared with the base oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com