Strain for producing long-chain diacid and application thereof

The technology of long-chain dibasic acid and dibasic acid is applied in the field of fermenting and producing long-chain dibasic acid and strains producing long-chain dibasic acid, which can solve the problems of electric energy consumption, narrow temperature adaptation range and large personnel input, etc. Achieve the effect of reducing power consumption, reducing production cost and wide temperature adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

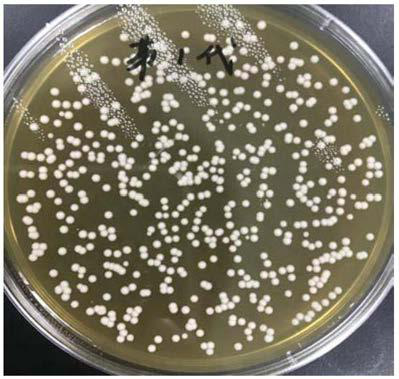

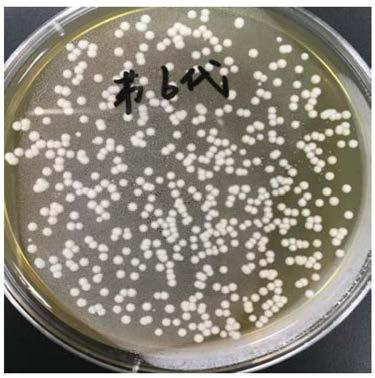

[0062] Tropical Candida yeast (Candida tropicalis) 10468 of the present invention, through subculture experiment verification, there is no significant change in the colony morphology and the ability to produce long-chain dibasic acid after five subcultures (see figure 1 , figure 2 ). Under the condition of 35°C, the DC12 produced by the first-generation and sixth-generation strains were 171.40g / L and 171.65g / L respectively after shake flask fermentation; colony morphology: the surface of the colony was smooth and moist, milky white, shiny, round, with neat edges. It can be seen that the passage stability of Candida tropicalis 10468 of the present invention is good.

Embodiment 2

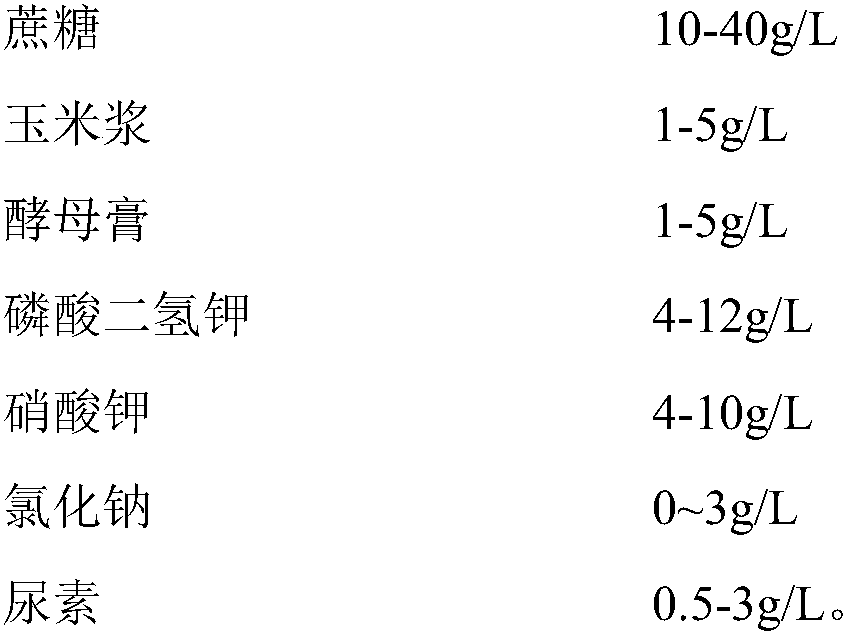

[0064] Take a glycerol tube seed and insert it into the YPD activation medium, cultivate for 36 hours, and then add the culture solution into the seed medium (cultivation is based on sterilization at 121°C for 20 minutes). Seed medium includes: sucrose 20g / L, corn steep liquor 2g / L, yeast extract 6g / L, potassium dihydrogen phosphate 8g / L, urea 2g / L, nC11 1mL; cultivated at 29°C for 48h, measured the seed liquid OD 620 Reached 0.8 (30 times of water dilution), the seed liquor is inoculated in the shaking flask that fermentation medium is housed, and fermentation medium comprises: sucrose 40g / L, corn steep liquor 5g / L, yeast extract 5g / L, dihydrogen phosphate Potassium 8g / L, potassium nitrate 4g / L, sodium chloride 1.5g / L, urea 0.5g / L. The n-alkane added to the fermentation medium was 1.5 mL nC11, and the fermentation medium was sterilized at 121° C. for 20 minutes. Fermented at 29°C. After the fermentation, the content of DC11 dibasic acid in the fermentation broth was determ...

Embodiment 3

[0066] Take a glycerol tube seed and insert it into the YPD activation medium, cultivate for 24 hours, and then add the culture solution into the seed medium (cultivation is based on sterilizing at 121°C for 20 minutes). Seed medium includes: sucrose 20g / L, corn steep liquor 4g / L, yeast extract 8g / L, potassium dihydrogen phosphate 12g / L, urea 1g / L, nC12 2ml; cultivated at 35°C for 48h, measured the seed liquid OD 620 Reached 0.6 (30 times of water dilution), the seed liquid is inoculated in the shaking flask that fermentation medium is housed, and fermentation medium comprises: sucrose 30g / L, corn steep liquor 3g / L, yeast extract 3g / L, dihydrogen phosphate Potassium 12g / L, potassium nitrate 7g / L, sodium chloride 1g / L, urea 1.5g / L. The n-alkane added to the fermentation medium was 3.5mL nC12, and the medium was sterilized at 121°C for 20 minutes. After the fermentation at 35°C, the content of DC12 dibasic acid in the fermentation broth was determined to be 172.53 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com