Tracking and controlling system of maximum wave energy of wave energy

A technology of tracking control and wave energy, which is applied in the direction of ocean energy power generation, electric vehicles, electrical components, etc., can solve the problems of low power generation efficiency, low energy collection efficiency, and unsuitable application environment, so as to increase power generation efficiency and improve battery life The effect of ability, good environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

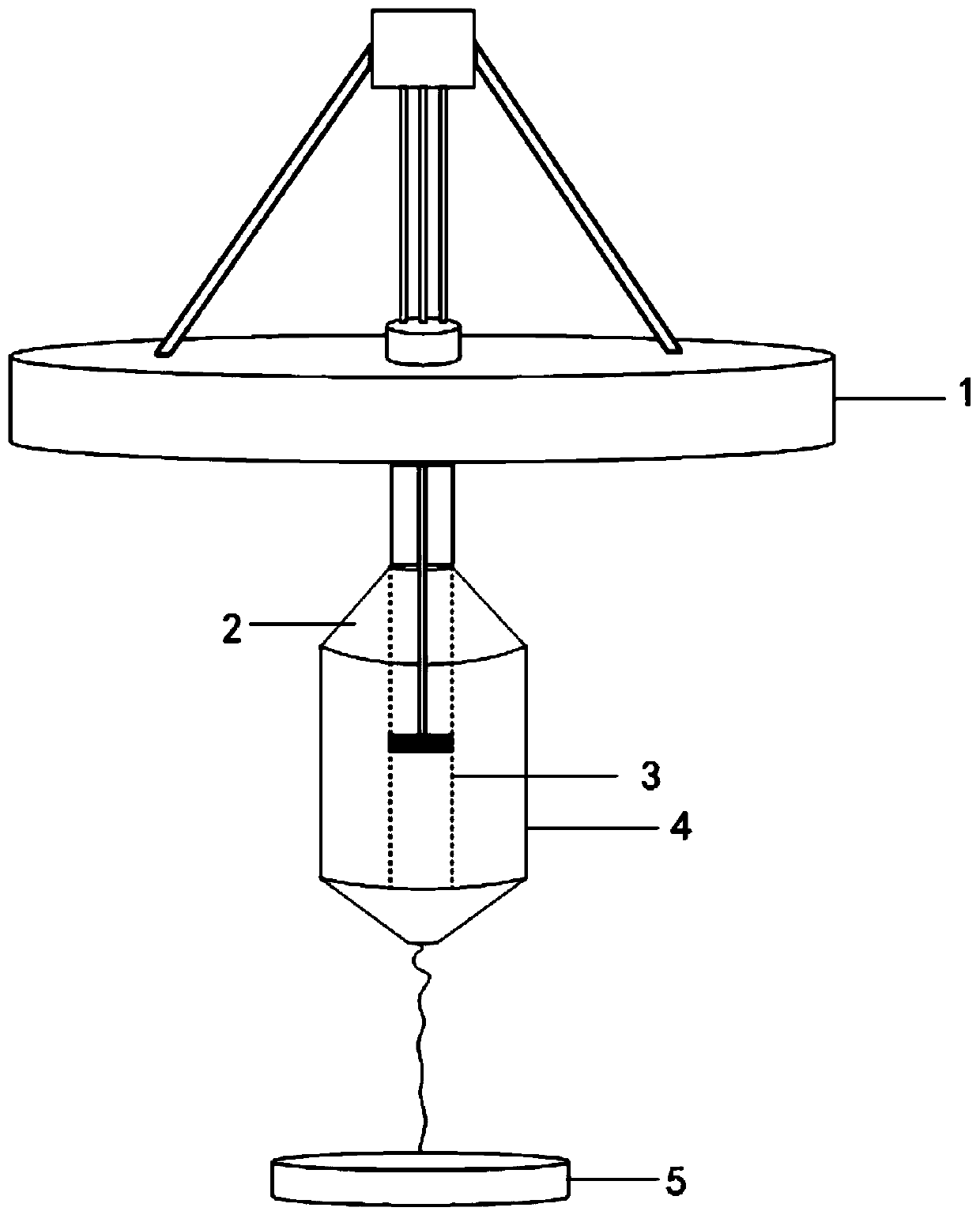

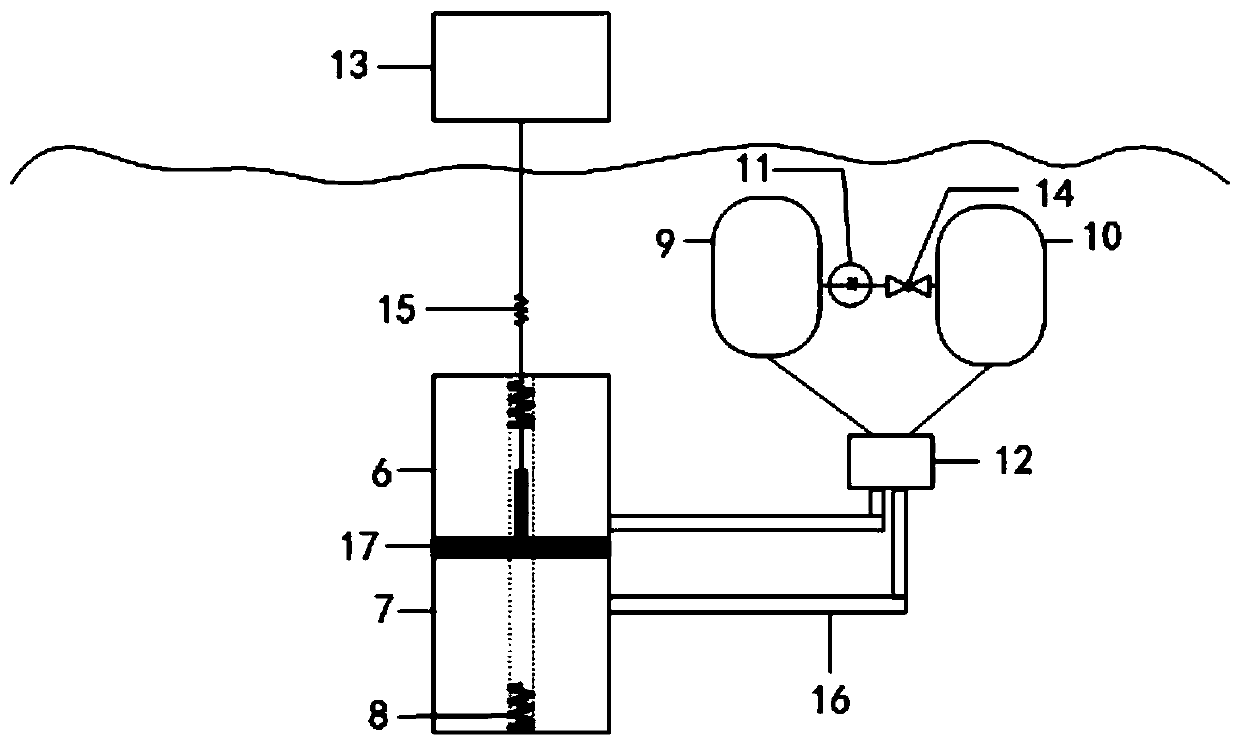

[0037] The controllable hydraulic system 2 uses hydraulic oil as the working medium for transferring energy, and the system is composed of a signal control part and a hydraulic power part. The signal control part transmits the sensor signal to the central controller through the vertical speed of the wave measured by the sensor, and the actuator is the speed of the hydraulic pump 11 and the state of the electromagnetic control valve 12; the hydraulic power part provides For the hydraulic pump 11 and the electromagnetic control valve 12, the hydraulic pump 11 controls the flow rate of the hydraulic oil, and the electromagnetic control valve controls the flow direction of the hydraulic oil 12. After the supplement of the hydraulic system, the movement of the stator is consistent with the up and down motion of the wave energy, forming resonance to achieve the maximum absorption of wave energy. Of course, the controllable hydraulic system 2 does not change in real time. Set differen...

Embodiment 2

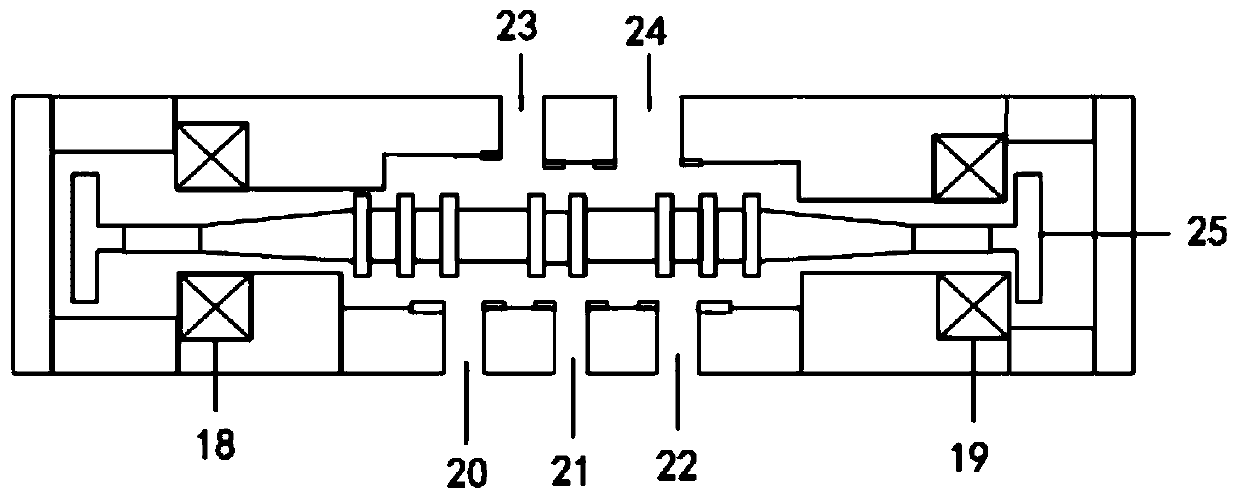

[0048] The electromagnetic control valve 12 includes a first electromagnetic coil 18, a second electromagnetic coil 19, a first liquid discharge port 20, a second liquid discharge port 22, a pressure port 21, a first port 23, a second port 24 and a spool 25; The port 21 is a machine port, the first port 23 is connected to the upper hydraulic chamber 6, the second port 24 is connected to the lower hydraulic chamber 7, the first liquid discharge port 20 is connected to the first hydraulic cylinder 9, and the second liquid discharge port 22 is connected to the second hydraulic cylinder 10. Controlling the energization of the first electromagnetic coil 18 and the second electromagnetic coil 19 through the controllable hydraulic system, so as to control the flow direction of the hydraulic oil, and then push the piston 17 to move up and down.

[0049] The specific implementation is as follows. When the piston 17 intends to move downward, the first electromagnetic coil 18 is energized...

Embodiment 3

[0052] The linear generator system 3 is a cylindrical permanent magnet synchronous linear motor with 12 slots and 11 poles, which includes a mover, a stator, a permanent magnet and a three-phase coil. The permanent magnet is attached to the surface of the mover, and the three-phase coil is embedded in the stator. in the slot. When the mover reciprocates up and down with the waves, it will move relative to the stator, thereby generating an induced electromotive force at the output end of the stator winding, realizing the conversion of wave energy into electrical energy. The cylindrical permanent magnet synchronous linear motor with 12 slots and 11 poles has a simple structure, which can realize the first-stage conversion of wave energy to electric energy, and effectively improve the conversion efficiency of wave energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com