Preparation method and application of carbon-coated ferrous borate with core-shell structure

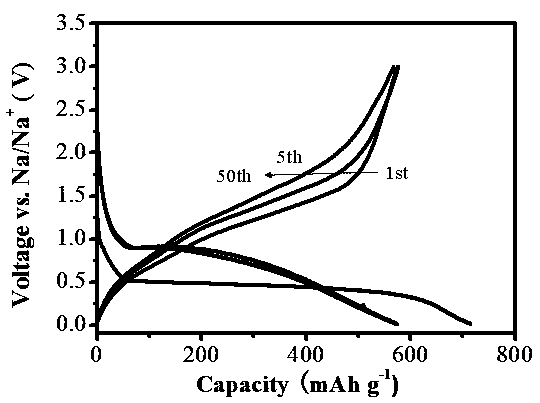

A technology of carbon-coated ferrous borate and core-shell structure, applied in structural parts, nanotechnology for materials and surface science, electrical components, etc., can solve the problems of negative electrode materials restricting practical applications, and achieve excellent application prospects. The effect of high purity and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Dissolve 0.8 g of ferric nitrate, 0.1 g of boric acid and 2 g of citric acid in 40 ml of deionized water, and stir magnetically for 2 h;

[0019] (2) Put the solution obtained in step (1) into a constant temperature drying oven, and react at a constant temperature of 100 °C for 12 hours to obtain a gel;

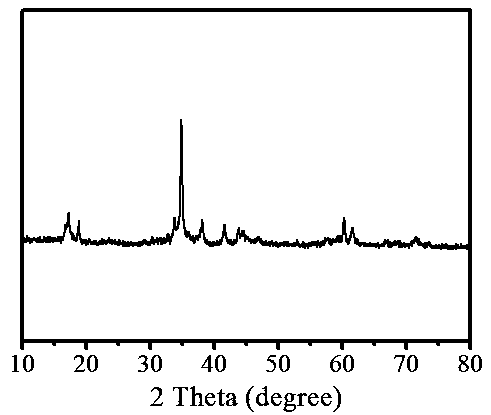

[0020] (3) Put the gel obtained in step (2) into a muffle furnace, anneal at 600 °C for 6 h to obtain a brown powder, and then grind for 6 h;

[0021] (4) Disperse the brownish-yellow powder ground in step (3) into 50 ml of 15 mM tris-hydroxymethylaminomethane solution, sonicate for 1 h, then add dopamine hydrochloride, stir for 5 h, wash with deionized water and ethanol After ultrasonic cleaning 3 times, dry at 60 °C;

[0022] (5) Put the powder obtained in step (4) into a tube furnace, and keep it warm at 400 °C for 5 h in an Ar atmosphere to prepare the carbon-coated ferrous borate ((FeO) 2 FeBO 3 @C);

[0023] (6) Assembly of sodium ion battery: according t...

Embodiment 2

[0025] (1) Dissolve 1.2 g of ferric nitrate, 0.3 g of boric acid and 4 g of citric acid in 70 ml of deionized water, and stir magnetically for 5 h;

[0026] (2) Put the solution obtained in step (1) into a constant temperature drying oven, and react at a constant temperature of 100-200 ℃ for 8-12 hours to obtain a gel;

[0027] (3) Put the gel obtained in step (2) into a muffle furnace, anneal at 800 °C for 2 h to obtain a brown-yellow powder, and then grind for 20 h;

[0028] (4) Disperse the brownish-yellow powder after grinding in step (3) into 100 ml of 5 mM tris-hydroxymethylaminomethane solution, sonicate for 5 h, then add dopamine hydrochloride, stir for 20 h, wash with deionized water and ethanol After ultrasonic cleaning several times, dry at 60 °C;

[0029] (5) Put the powder obtained in step (4) into a tube furnace, and keep it warm at 700°C for 2 h in an Ar atmosphere to prepare the carbon-coated ferrous borate ((FeO) 2 FeBO 3 @C);

[0030] (6) Assembly of sodi...

Embodiment 3

[0032] (1) Dissolve 1.0 g of ferric nitrate, 0.2 g of boric acid and 3 g of citric acid in 55 ml of deionized water, and stir magnetically for 3.5 hours;

[0033] (2) Put the solution obtained in step (1) into a constant temperature drying oven, and react at a constant temperature of 150 °C for 10 h to obtain a gel;

[0034] (3) Put the gel obtained in step (2) into a muffle furnace, anneal at 700 °C for 4 h to obtain a brown-yellow powder, and then grind for 13 h;

[0035] (4) Disperse the brownish-yellow powder ground in step (3) into 75 ml of 10 mM tris-hydroxymethylaminomethane solution, sonicate for 3 h, then add dopamine hydrochloride, stir for 12 h, wash with deionized water and ethanol After ultrasonic cleaning several times, dry at 60 °C;

[0036] (5) Put the powder obtained in step (4) into a tube furnace, and keep it warm at 550°C for 3.5 h in an Ar atmosphere to prepare the carbon-coated ferrous borate ((FeO) 2 FeBO 3 @C);

[0037] (6) Assembly of sodium ion ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com