Porous carbon oxygen reduction catalyst and preparation method and application thereof

A catalyst and porous carbon technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of complicated preparation process and high cost of catalyst preparation, and achieve the effects of simple process, good electrocatalytic performance and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Take 4 g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer sample (molecular weight: 12600 g / mol), add 100 ml of deionized water, stir well, and obtain a clear and transparent solution.

[0026] 2) Add 1.6g of zinc chloride to the solution, and after clarification, add 1g of potassium hydroxide. After no more precipitation, move it into the reaction kettle, set the hydrothermal temperature to 80°C, keep it warm for 12h, then take it out, and dry it at 60°C for 24h to Transparent film-like substance.

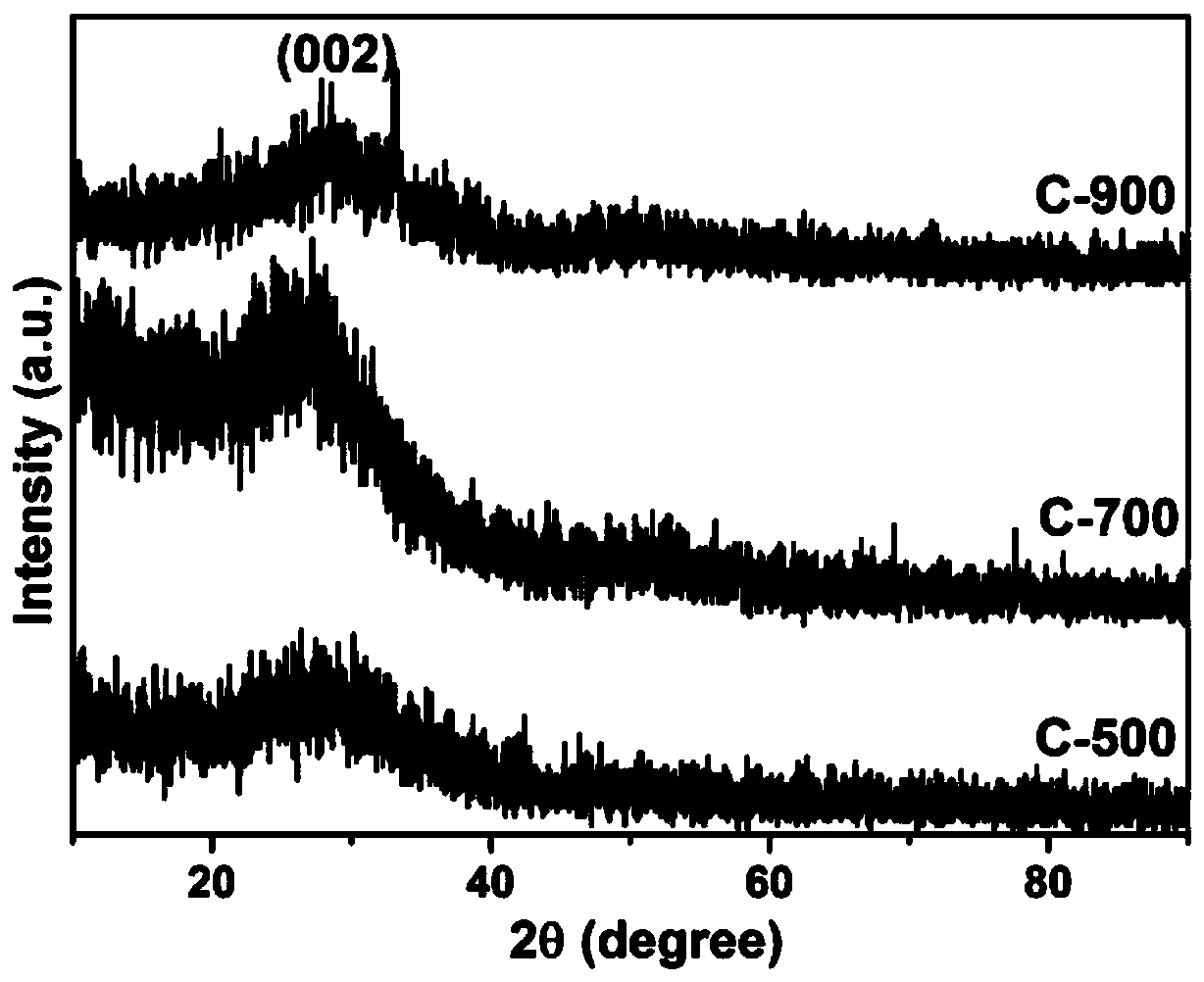

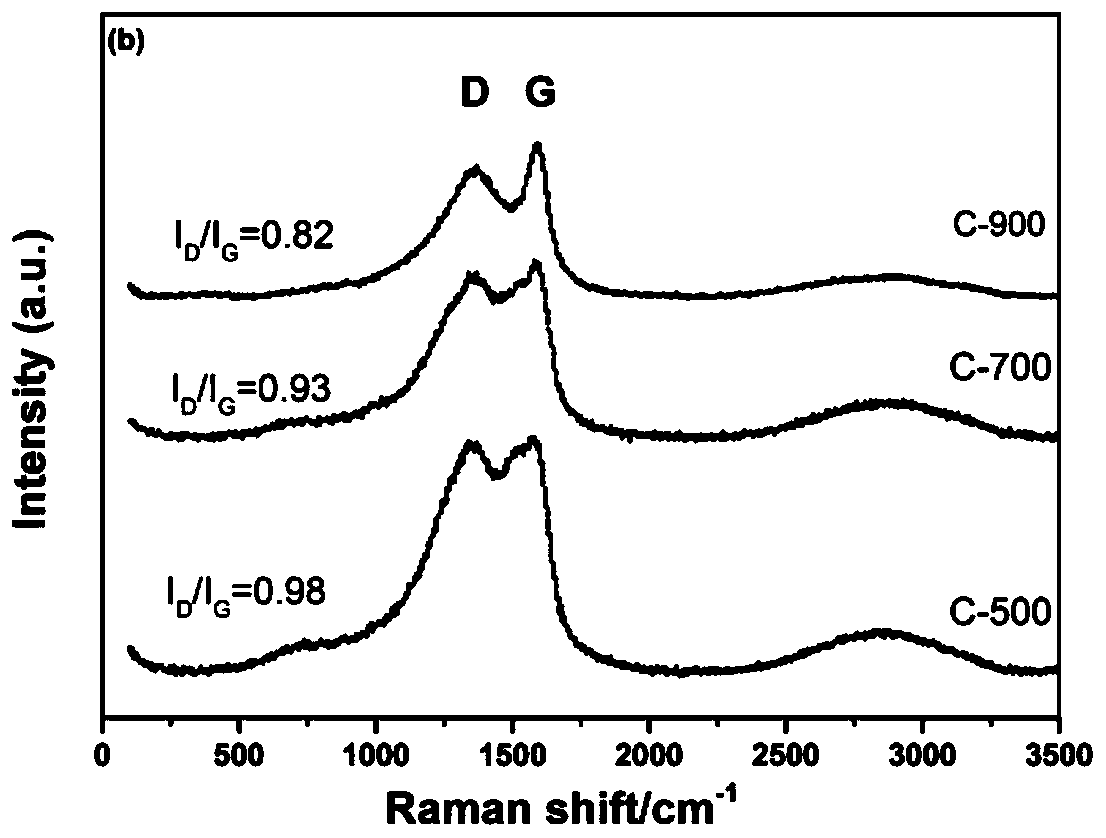

[0027] 3) Carry out carbonization treatment of the transparent film-like substance in a tube furnace with nitrogen gas. The carbonization procedure is as follows: from room temperature to 500°C at a heating rate of 2°C / min, keep it warm for 3h, then cool to room temperature with the furnace, and take it out; First soak in 2mol / L HCl solution, centrifuge with deionized water at 4000r / min for 5min, repeat centrifugation to neutrality, then ce...

Embodiment 2

[0029] 1) Take 4 g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer sample (molecular weight: 12600 g / mol), add 100 ml of deionized water, stir well, and obtain a clear and transparent solution.

[0030] 2) Add 1.6g of zinc chloride to the solution, and after clarification, add 1g of potassium hydroxide. After no more precipitation, move it into the reaction kettle, set the hydrothermal temperature to 80°C, keep it warm for 12h, then take it out, and dry it at 60°C for 24h to Transparent film-like substance.

[0031] 3) Carbonize the transparent film-like substance in a tube furnace with nitrogen gas. The carbonization procedure is as follows: from room temperature to 700°C at a heating rate of 2°C / min, keep it warm for 3 hours, then cool to room temperature with the furnace, and take it out; First soak in 2mol / L HCl solution, centrifuge with deionized water at 4000r / min for 5min, repeat centrifugation to neutrality, then centrifugally wash with ...

Embodiment 3

[0033] 1) Take 4 g of polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer sample (molecular weight: 12600 g / mol), add 100 ml of deionized water, stir well, and obtain a clear and transparent solution.

[0034] 2) Add 1.6g of zinc chloride to the solution, and after clarification, add 1g of potassium hydroxide. After no more precipitation, move it into the reaction kettle, set the hydrothermal temperature to 80°C, keep it warm for 12h, then take it out, and dry it at 60°C for 24h to Transparent film-like substance.

[0035] 3) Carbonize the transparent film-like substance in a tube furnace filled with nitrogen. The carbonization procedure is as follows: from room temperature to 900°C at a heating rate of 2°C / min, keep it warm for 3 hours, then cool to room temperature with the furnace, and take it out; First soak in 2mol / L HCl solution, centrifuge with deionized water at 4000r / min for 5min, repeat centrifugation to neutrality, then centrifugally wash wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pyrolysis temperature | aaaaa | aaaaa |

| Pyrolysis temperature | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap