Soil cultivation agent and preparation method thereof

A soil and water-retaining agent technology, applied in the directions of botanical equipment and methods, culture medium, planting substrate, etc., can solve the problems of low survival rate of afforestation, low utilization rate of water resources, increased afforestation cost, etc., and improve the ability to retain water and fertilizer. , Improve the survival rate of planting, reduce the effect of watering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A soil cultivation agent, comprising the following components in parts by weight: 2-6 parts of linseed gum, 50-150 parts of organic fertilizer, 6-18 parts of water-retaining agent, 2-6 parts of humic acid, and 800-2400 parts of water .

[0032] Flaxseed gum, also known as Frank gum, exists in the husk of flaxseeds. It is a natural polymer composite glue with polysaccharides and proteins as the main components, and a natural thickener. The content of flaxseed gum in flaxseed varies greatly with the variety of flaxseed, and the general content is 8-10%. Flaxseed gum is a kind of pure natural, pollution-free, multifunctional and nutritious plant gum. It is a green food additive certified by the National Green Food Development Center. It has high nutritional content, high viscosity, strong water absorption, good emulsifying effect, and Heavy metals have the characteristics of adsorption and detoxification, and also have the effects of skin care, beauty, and health care. Th...

Embodiment 2

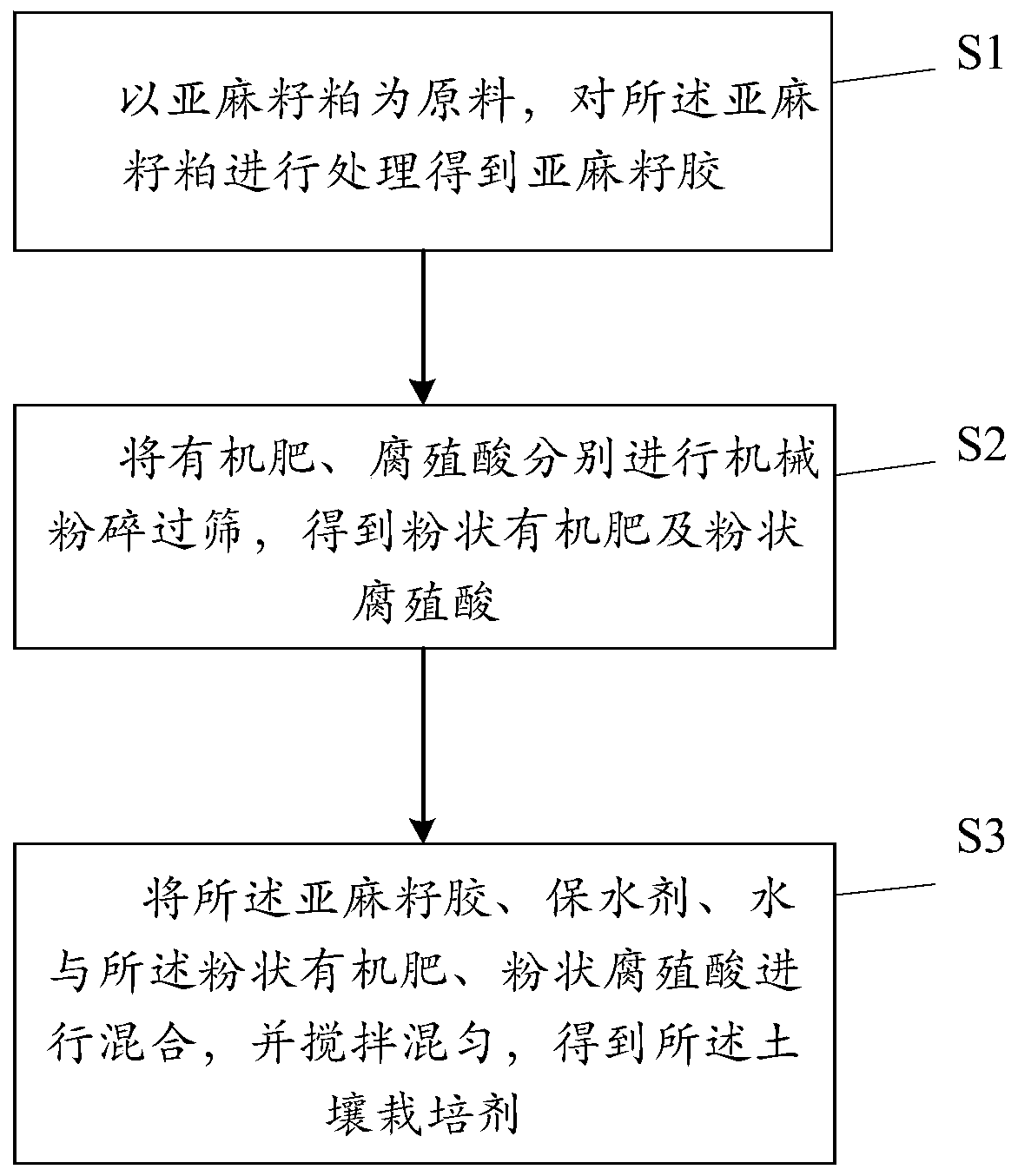

[0052] Such as figure 1 As shown, a preparation method of the above-mentioned soil cultivation agent includes step S1 to step S3.

[0053] Step S1, using linseed meal as a raw material, and processing the linseed meal to obtain linseed gum.

[0054] Further, the step S1 includes step S11 to step S15.

[0055] Step S11, crushing and sieving the linseed meal to obtain linseed hulls.

[0056] Among them, linseed meal is a by-product of linseed oil extraction.

[0057] Specifically, the linseed meal can be crushed with a grinder, and the crushed linseed meal can be collected, passed through a 20 to 30 mesh sieve, and the upper linseed husk obtained after sieving can be collected.

[0058] Step S12, mixing the linseed hulls with water, and performing extraction treatment to obtain a mixed material liquid.

[0059] Further, the linseed hulls can be mixed with water according to a mass ratio of 1:20-30, and microwave-assisted hot water extraction is carried out for 40-60 minutes ...

Embodiment 3

[0075] A soil cultivation agent, comprising the following components in parts by weight: 2 parts of linseed gum, 50 parts of organic fertilizer, 6 parts of water-retaining agent, 2 parts of humic acid, and 800 parts of water.

[0076] The preparation method of the above-mentioned soil cultivation agent is as follows.

[0077] The linseed meal is used as a raw material, and the linseed meal is processed to obtain linseed gum.

[0078] Mechanically pulverize and sieve the organic fertilizer and humic acid respectively to obtain powdery organic fertilizer and powdery humic acid.

[0079] The linseed gum, the water-retaining agent, water, the powdered organic fertilizer and the powdered humic acid are mixed, and stirred evenly to obtain the soil cultivation agent.

[0080] The soil cultivation agent provided in this example can effectively increase the content of soil nutrients and the number of beneficial microorganisms within the distribution range of sand-suitable trees and sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com