Method used for flue gas denitration with pyrolysis acid pickling sludge

A technology of pickling sludge and pyrolysis, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., to achieve the effect of solving treatment problems, simple operation and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

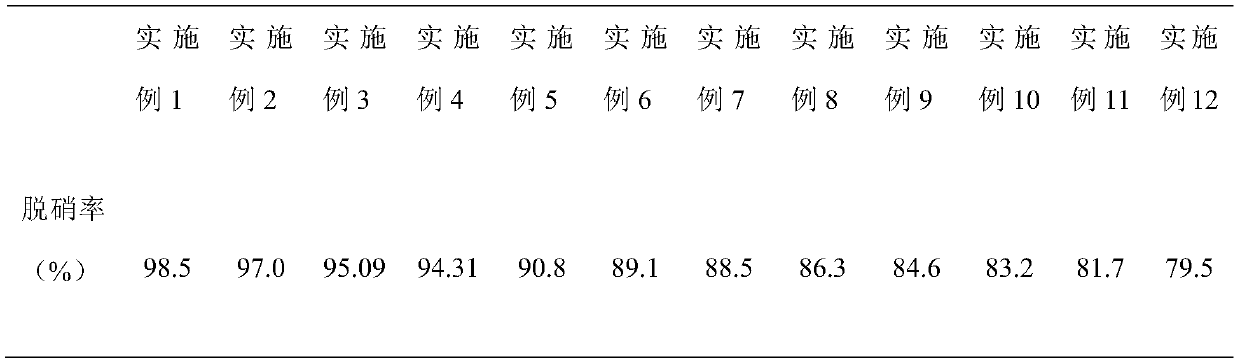

Embodiment 1

[0024] In flue gas conditions of 1000ppmNO, 1%O 2 , N 2 For balance gas, when the total gas flow rate is 450ml / min, and the temperature condition is 600°C, 1g of carbon powder is added to a tube furnace with a diameter of 3cm, and the denitrification rate reaches 98.5%.

Embodiment 2

[0026] In flue gas conditions of 1000ppmNO, 1%O 2 , N 2 For balance gas, when the total gas flow rate is 450ml / min, and the temperature condition is 700°C, 1g of carbon powder is added to a tube furnace with a diameter of 3cm, and the denitrification rate reaches 96.0%.

Embodiment 3

[0028] In flue gas conditions of 1000ppmNO, 1%O 2 , N 2 For balance gas, when the total gas flow rate is 450ml / min, and the temperature condition is 800°C, 1g of carbon powder is added to a tube furnace with a diameter of 3cm, and the denitrification rate reaches 95.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com