Method for brewing sweet banana fruit wine with obvious banana flavor characteristics and low alcohol content

A low-alcohol, fruit wine brewing technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of loss, difficulty in synergistically forming banana characteristic flavor, lack of sugar sweetness, etc., to reduce loss, low alcohol, and reduce volatilization loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

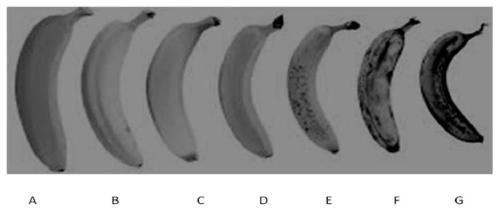

[0039] Use Shandong Zunhuang 30L fermenter with refrigeration, the ratio of diameter to height of the fermenter is 1:2, and there is a titanium rod at the bottom of the fermenter, which can be used for carbon dioxide washing. The process route used is: sorting of bananas → insulation in water bath with skin → blanching → color protection → beating → enzymatic hydrolysis → filtration → inoculation → low-temperature restricted fermentation → centrifugal clarification → membrane filtration → packaging of finished products.

[0040] Yeast expansion: Use the yeast strain BBW-05 with a relatively high yield of isoamyl acetate screened from the Beibu Gulf University’s own microbial library; use 10°P whole malt wort to cultivate at 16°C, start from one colony, and then use small test tubes, Large test tubes, 100ml Erlenmeyer flasks, and 1000ml Erlenmeyer flasks are gradually expanded to the amount of yeast required for fermentation. During the expansion process, when the yeast concent...

example 1

[0057] Summary of the comparison between Example 1 and Comparative Example: The team of the present invention is not limited to the yeast selection, yeast management (addition amount, addition of yeast sludge), fermentation conditions (dissolved oxygen, fermentation temperature, Fermentation tank diameter-to-height ratio) links have been tested, and it is found that they all affect the fermentation intensity and fermentation behavior of banana wine, and then change the flavor composition (especially isoamyl acetate and isoamyl alcohol) and physicochemical composition of banana wine. People's sensory perception of banana wine. As demonstrated in Example 1, the selection of yeast described in the patent, yeast management (addition amount, addition of yeast sludge), fermentation operation (dissolved oxygen, fermentation temperature, diameter-to-height ratio of the fermenter), combined with the raw materials described in the patent Selection and pretreatment conditions of banana j...

Embodiment 2

[0059] Use Shandong Zunhuang 30L fermenter with refrigeration, the ratio of diameter to height of the fermenter is 1:2, and there is a titanium rod at the bottom of the fermenter, which can be used for carbon dioxide washing. The process route used is: sorting of bananas → insulation in water bath with skin → blanching → color protection → beating → enzymatic hydrolysis → filtration → inoculation → low-temperature restricted fermentation → centrifugal clarification → membrane filtration → packaging of finished products.

[0060] Yeast expansion: Use the yeast strain BBW-05 with relatively high ester yield of isoamyl acetate screened from the Beibu Gulf University’s own microbial library; use 10°P whole malt wort to cultivate at 16°C, start from one colony, and grow through small test tubes, Large test tubes, 100ml Erlenmeyer flasks, and 1000ml Erlenmeyer flasks are gradually expanded to the amount of yeast required for fermentation. During the expansion process, when the yeast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com