Method for treating heavy metal in solid waste incineration fly ash through magnetite modification

A technology for solid waste and fly ash incineration, which is applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc. It can solve the problems of secondary wastes that are rarely discussed, and achieve rich raw materials and extraction effects. Good, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

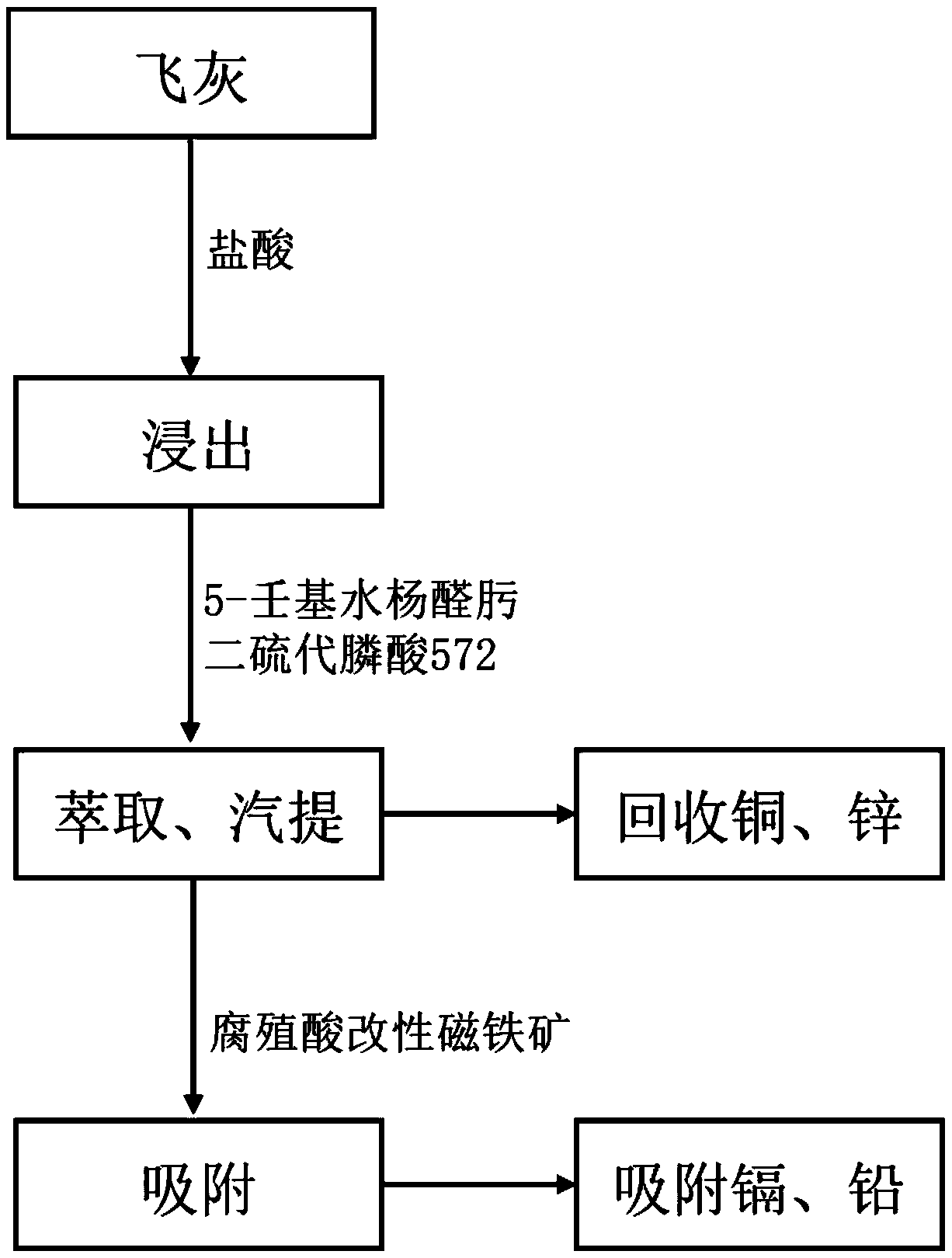

[0040] A kind of embodiment of the method that the present invention utilizes magnetite modifier to process heavy metals in solid waste incineration fly ash, the method comprises the following steps:

[0041] (1) Leaching of heavy metals in fly ash containing copper, zinc, cadmium and lead: mix hydrochloric acid with a pH value of 2 and fly ash at a weight ratio of 14:1, and stir for 20 hours to obtain a leachate, and measure copper, The leaching rate of cadmium is close to 100%, and the leaching rate of zinc and lead is 80-85%;

[0042] (2) Extract metal zinc and copper: get 10 parts by volume of the leaching solution obtained in step (1) to adjust the pH value to 4, and then use 10 parts by volume of 5-nonylsalicylaldoxime concentration of 1mol / L of 5 -The mixed solution of nonylsalicylaldoxime and kerosene extracts it, obtains aqueous phase A and the organic phase of loading copper, then uses 10 parts by volume of dithiophosphonic acid 572 concentration to be the dithiophos...

Embodiment 2

[0045] A kind of embodiment of the method that the present invention utilizes magnetite or its modifiers to process heavy metals in solid waste incineration fly ash, the method comprises the following steps:

[0046] (1) Leaching of heavy metals in fly ash containing copper, zinc, cadmium and lead: mix hydrochloric acid with a pH value of 2 and fly ash at a weight ratio of 10:1, and stir for 18 hours to obtain a leachate, and measure copper, The leaching rate of cadmium is close to 100%, and the leaching rate of zinc and lead is 78-82%;

[0047] (2) Extract metal zinc and copper: get 10 parts by volume of the leaching solution obtained in step (1) to adjust the pH value to 4, and then use 8 parts by volume of 5-nonylsalicylaldoxime concentration of 1mol / L of 5 -The mixed solution of nonylsalicylaldoxime and kerosene extracts it, obtains aqueous phase A and the organic phase of loading copper, then uses 8 parts by volume of dithiophosphonic acid 572 concentration to be the dith...

Embodiment 3

[0050] A kind of embodiment of the method that the present invention utilizes magnetite or its modifiers to process heavy metals in solid waste incineration fly ash, the method comprises the following steps:

[0051] (1) Leaching of heavy metals in fly ash containing copper, zinc, cadmium and lead: mix hydrochloric acid with a pH value of 2 and fly ash at a weight ratio of 15:1, and stir for 24 hours to obtain a leachate, and measure copper, The leaching rate of cadmium is close to 100%, and the leaching rate of zinc and lead is 82-85%;

[0052] (2) Extract metal zinc and copper: get 10 parts by volume of the leaching solution obtained in step (1) to adjust the pH value to 4, and then use 15 parts by volume of 5-nonylsalicylaldoxime concentration of 1mol / L of 5 -The mixed solution of nonylsalicylaldoxime and kerosene extracts it, obtains aqueous phase A and the organic phase of loading copper, then uses 15 parts by volume of dithiophosphonic acid 572 concentration to be the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com