High-strength-plasticity-toughness multi-main-element alloy and preparation method thereof

A technology of multi-principal alloy and ductility, which is applied in the field of high-strength plastic-toughness multi-principal alloy and its preparation, can solve the problems that no scholars have researched cost multi-principal alloy, so as to promote the formation of BCC phase and alloy Effects of increased hardness and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

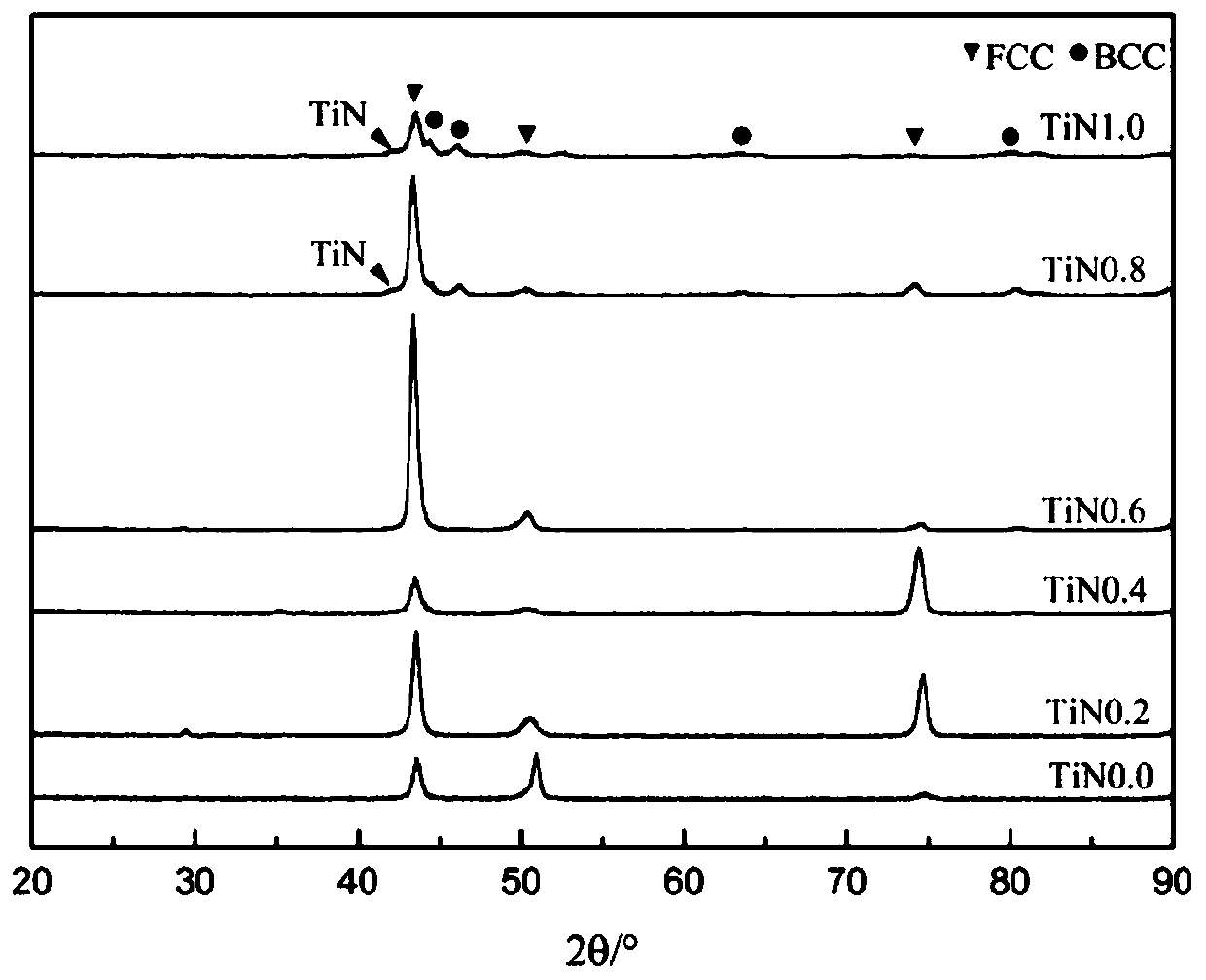

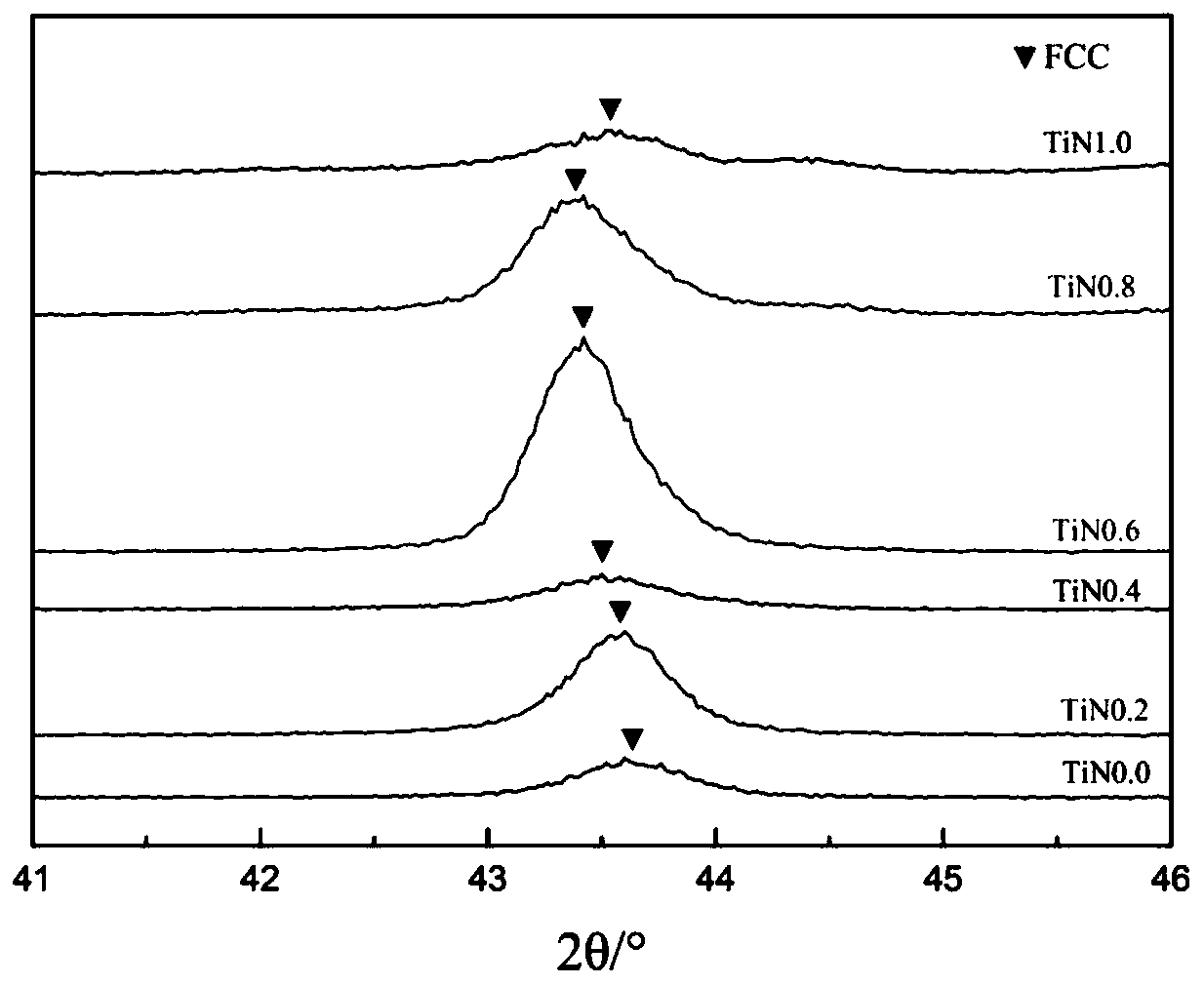

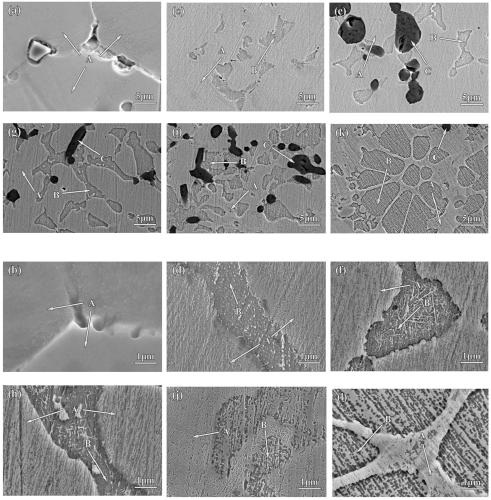

[0026] 1) Use an electronic balance to accurately weigh the smelting raw materials, and separate the Al, Cr, Fe, Ni, and TiN single mass blocks with a purity higher than 99.9% according to the mole fraction of Al 0.5 Cr 0.9 FeNi 2.5 TiN x (x=0.0,0.2,0.4,0.6,0.8,1.0) is prepared;

[0027] 2) Vacuum arc melting: Vacuum the electric arc furnace to a vacuum degree of (4.5-4.8)×10 -3 Pa, and then under the high-purity argon atmosphere with a purity greater than 99.999%, fill high-purity argon to a vacuum of -0.05Mpa, and conduct arc melting at a current of 150A-300A to prepare Al 0.5 Cr 0.9 FeNi 2.5 TiN x (x=0.0, 0.2, 0.4, 0.6, 0.8, 1.0) alloy ingots, each about 30g. During preparation, the ingot was inverted and remelted at least 5 times to improve chemical uniformity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hardness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com