A capacitive humidity sensor based on an "arch" structure and its preparation method and application

A humidity sensor, capacitive technology, applied in material capacitance, instruments, scientific instruments, etc., can solve the problem of inability to precisely control the morphology and size of polymers, and achieve short response/recovery time, controllable morphology, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

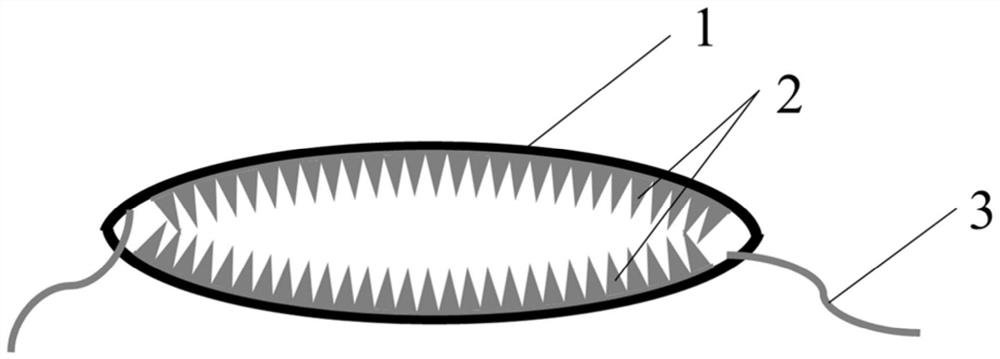

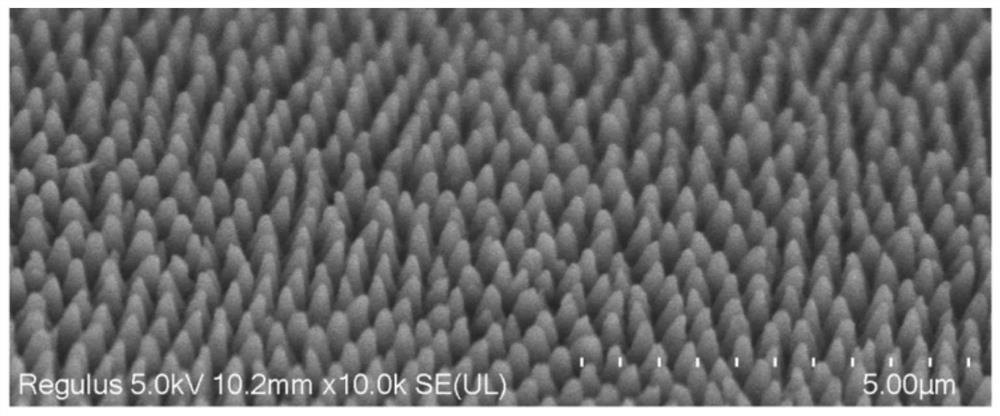

[0052] refer to figure 1 , a capacitive humidity sensor based on an "arch" structure, including an electrode 1, a dielectric layer 2 and a wire 3, the electrode 1 includes a top electrode and a bottom electrode, both of which are "arch" structures, and the top electrode The dielectric layer 2 of the arrayed nanocone structure is arranged on the bottom electrode, and the cone tip faces away from the surface of the electrode where it is located. The top electrode and the bottom electrode are assembled to form a ring structure, and the dielectric layers on the two electrodes are located in the ring The inner side of the structure; wires 3 are arranged on the top electrode and the bottom electrode.

Embodiment 2

[0054] A capacitive humidity sensor based on an "arch" structure, the same as in Embodiment 1, the difference is that: the top electrode and the bottom electrode are both composed of a flexible PET substrate and ITO attached to the substrate, that is, phthalic acid Glycol ester-indium tin oxide (PET-ITO). The material of the dielectric layer is polyvinylidene fluoride-trifluoroethylene (P(VDF-TrFE)).

Embodiment 3

[0056] A method for preparing a capacitive humidity sensor based on an "arch" structure, comprising the steps of:

[0057] (1) Preparation of porous tapered nanopore template AAO, the specific steps are as follows:

[0058] (1-1) Soak the aluminum sheet in acetone, ethanol, and deionized water in sequence, ultrasonically clean each for 15 minutes, then move to a plasma-enhanced chemical vapor deposition (PECVD) device, anneal at 600°C for 10 hours, and then place the aluminum sheet on a single Surface electropolishing;

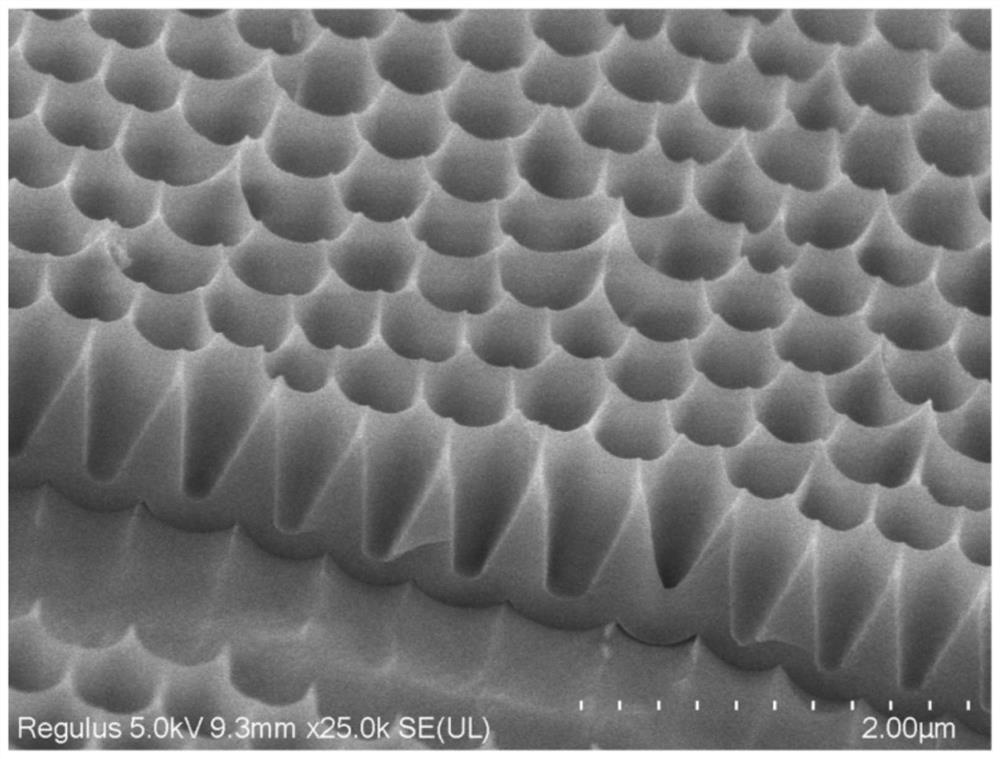

[0059] (1-2) Embossing the surface of the electropolished aluminum sheet through a silicon mold with a honeycomb nanocone structure to produce a nano-depression array;

[0060] (1-3) With the aluminum sheet obtained in step (1-2) as the anode, the lead block as the cathode, and 0.4mol / L oxalic acid as the electrolyte, a direct current (DC) voltage of 215V is used, and the reaction time is 2h. orderly oxide film, soak the aluminum sheet after the first oxidat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com