Lead-acid storage battery pole plate, lead-acid storage battery, preparation methods and application

A lead-acid battery and plate technology, which is applied in the direction of lead-acid battery electrodes, lead-acid batteries, lead-acid battery construction, etc., can solve problems such as increased internal resistance, inactivation of active materials, and low efficiency of electric energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] Example 1 (the metal barium plate accounts for 10wt.% in the composite plate C, and the lead-barium alloy plate containing 0.5wt.% barium accounts for 90wt.%; the barium element accounts for 10.45wt.% in the pole plate)

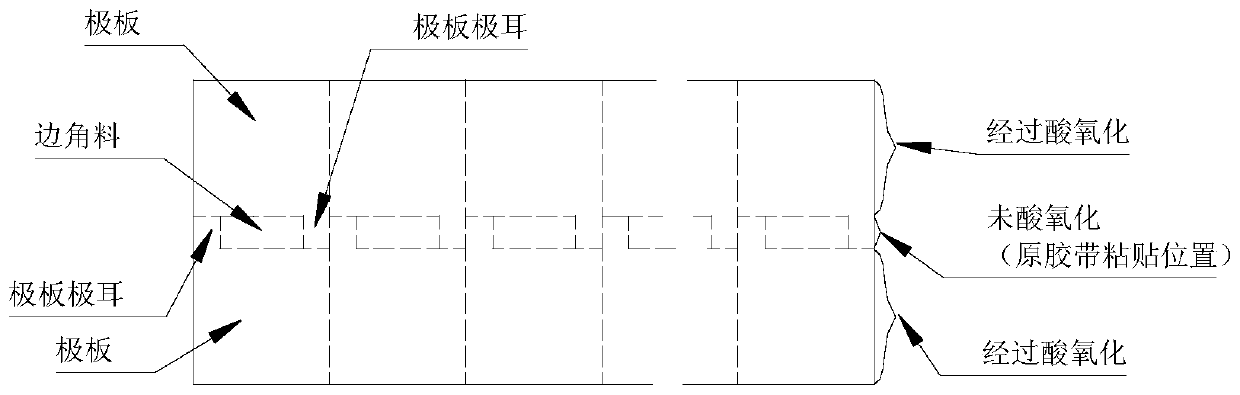

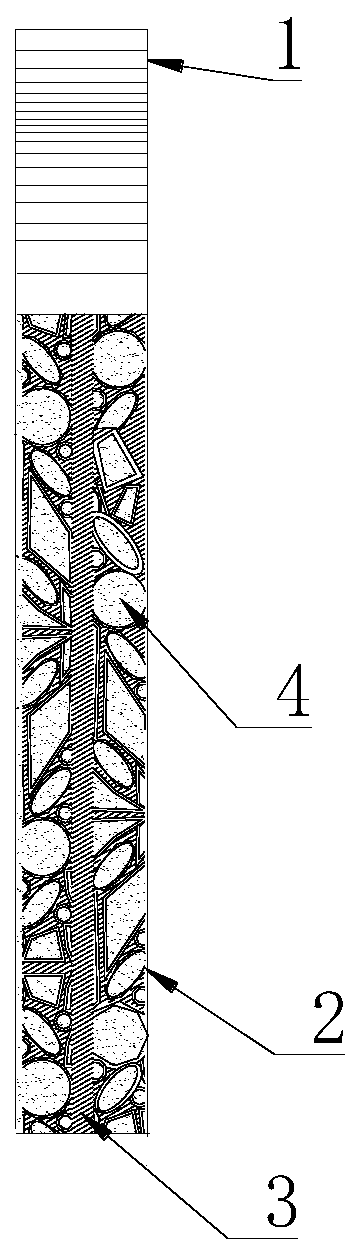

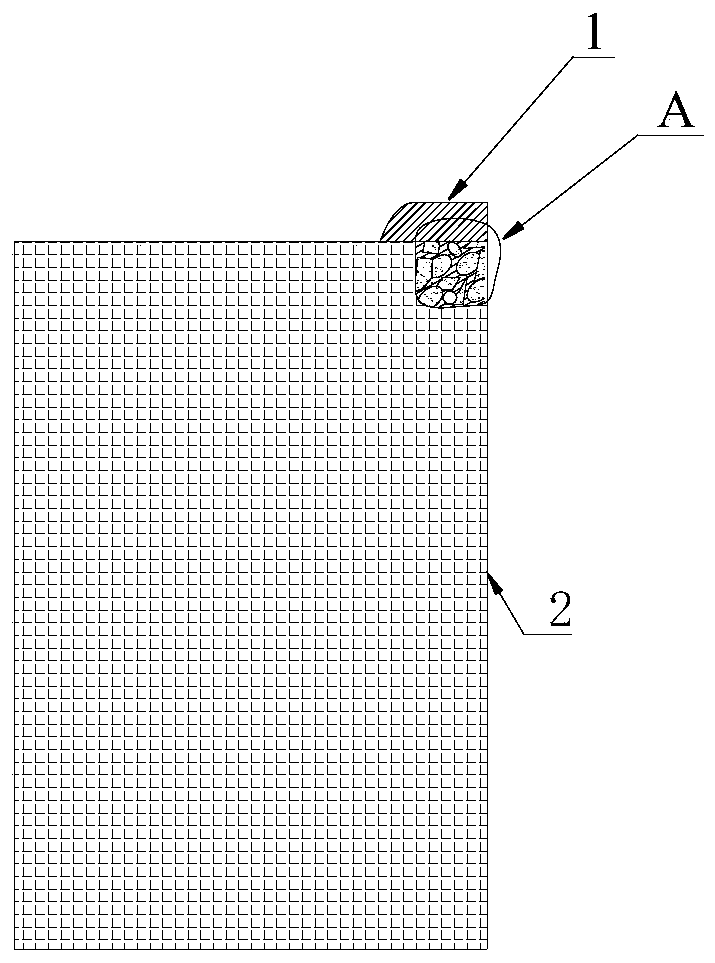

[0093] (1) Melt and cast the analytically pure barium particles to obtain a barium bar with a specification of 20mm×4mm×40mm and a barium content of 99.95wt.%. 4mm × 40mm, barium-containing 0.5wt.% lead-barium alloy strip; under nitrogen atmosphere, use boron glass material pressure roller to roll the barium strip containing barium 99.95wt.% into a 0.1mm thick metal barium plate, get A Plate, the barium-containing 0.5wt.% lead-barium alloy bar is rolled into a lead-barium alloy plate with a thickness of 0.2mm, the same width as plate A, and twice the area to obtain plate B (alloy phase composition is BaPb 3 and αBaPb crystallite); according to the "B-A-B" way to stack A and B boards, use the same material with double-rollers with shallow concave-conv...

Embodiment 2

[0097] Example 2 (the metal barium plate accounts for 5wt.% in the composite plate C, and the lead-barium alloy plate containing barium 1wt.% accounts for 95wt.%; the barium element accounts for 5.95wt.% in the pole plate)

[0098] (1) Melt and cast the analytically pure barium particles to obtain a barium bar with a specification of 20mm×4mm×40mm and a barium content of 99.95wt.%. 4mm×40mm, lead-barium alloy strip containing 1wt.% barium; under a nitrogen atmosphere, roll the barium strip containing 99.95wt.% barium into a 0.1mm thick metal barium plate with a boron glass material pressure roller to obtain a plate A , the barium-containing 1wt.% lead-barium alloy bar is rolled into a lead-barium alloy plate with a thickness of 0.3mm, the same width as plate A, and twice the area to obtain plate B (alloy phase composition is BaPb 3 and αBaPb crystallite); according to the "B-A-B" way to stack A and B boards, use the same material with double-rollers with shallow concave-conv...

Embodiment 3

[0102] Example 3 (the metal barium plate accounts for 3wt.% in the composite plate C, and the lead-barium alloy plate containing barium 2wt.% accounts for 97wt.%; the barium element accounts for 4.94wt.% in the pole plate)

[0103] (1) Melt and cast the analytically pure barium particles to obtain a barium bar with a specification of 20mm×4mm×40mm and a barium content of 99.95wt.%. 4mm×40mm, lead-barium alloy strip containing 2wt.% barium; under a nitrogen atmosphere, roll the barium strip containing 99.95wt.% barium into a 0.2mm thick metal barium plate with a boron glass material pressure roller to obtain a plate A , the barium-containing 2wt.% lead-barium alloy bar is rolled into a lead-barium alloy plate with a thickness of 0.4mm, the same width as plate A, and twice the area to obtain plate B (alloy phase composition is BaPb 3 and αBaPb crystallite); according to the "B-A-B" way to stack A and B boards, use the same material with double-rollers with shallow concave-conv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com