Culture soil for improving survival rate of camellia oleifera seedlings and preparation method thereof

A technology for safflower camellia and culturing soil, which is applied in the directions of botanical equipment and methods, culture medium, chemical instruments and methods, etc., can solve problems such as low production cost, ensure the supply of nutrients, improve the survival rate of seedlings, and realize the reduction of waste. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of this culture soil, comprises the steps:

[0040] Step S1, weighing each raw material according to parts by weight;

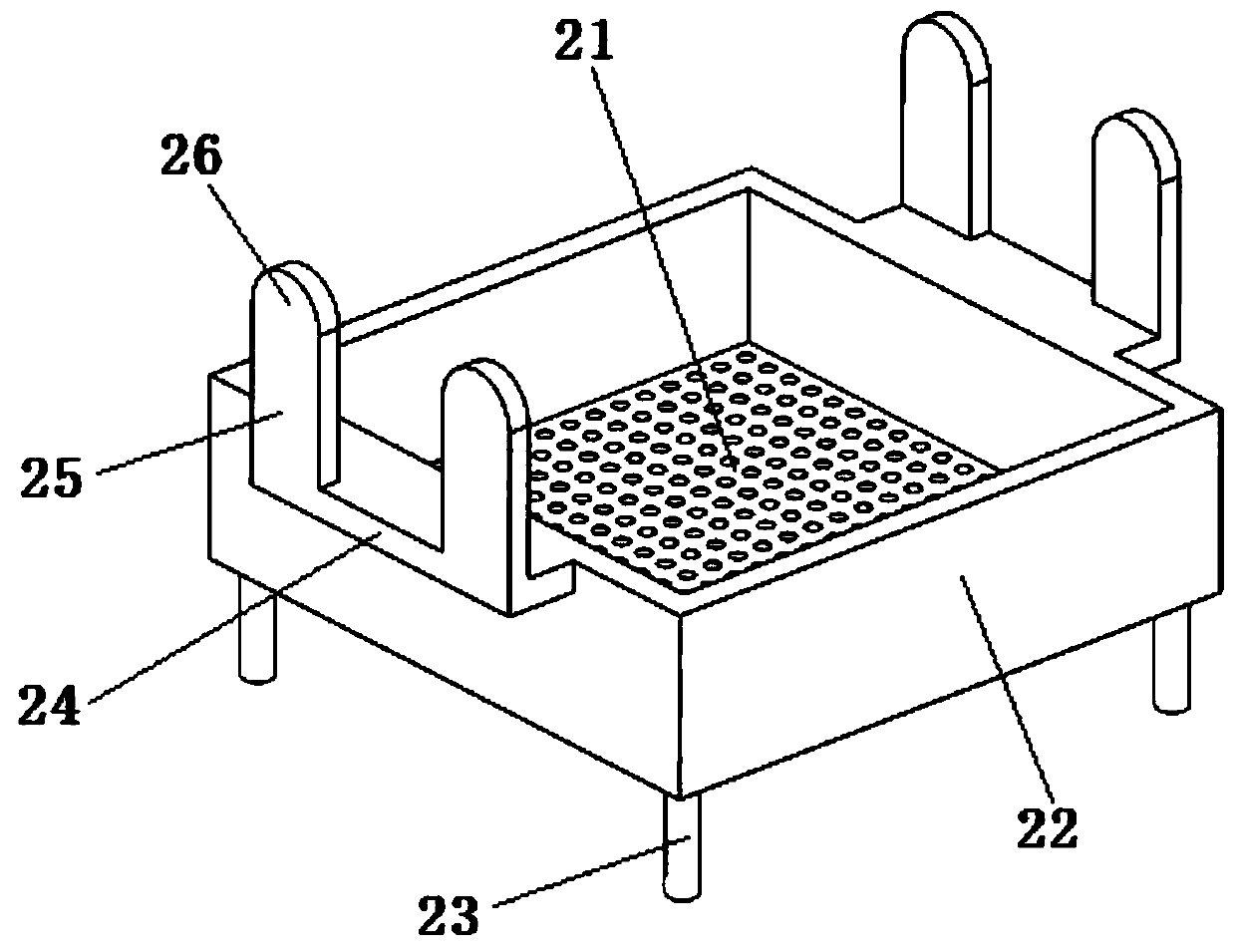

[0041] Step S2, place each raw material on the loading plate 21 of the culture soil production device, turn on the motor connected to the first shaft 3101, and simultaneously turn on the steam connected to the steam storage box 14, and place each raw material in the culture soil production device Treat for 20-30min;

[0042] Step S3, turn off the motor and the steam source, and after the mixed material on the loading plate 21 is cooled to normal temperature, discharge the material to prepare culture soil;

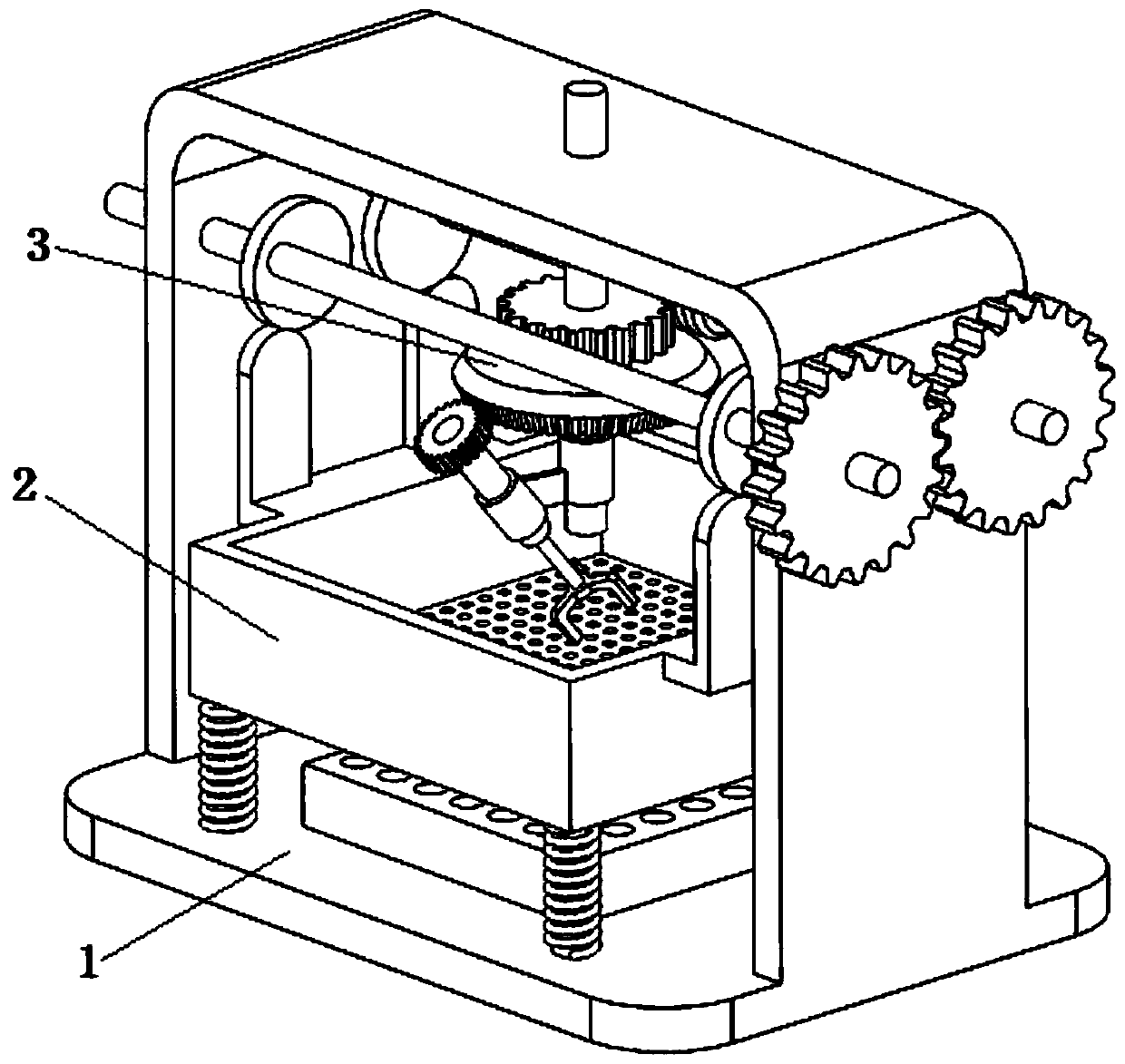

[0043] see Figure 1-6 As shown, the culture soil production device, such as figure 1 As shown, it includes a carrier device 1 and a mixing device 2 and a linkage device 3 installed on the carrier device 1;

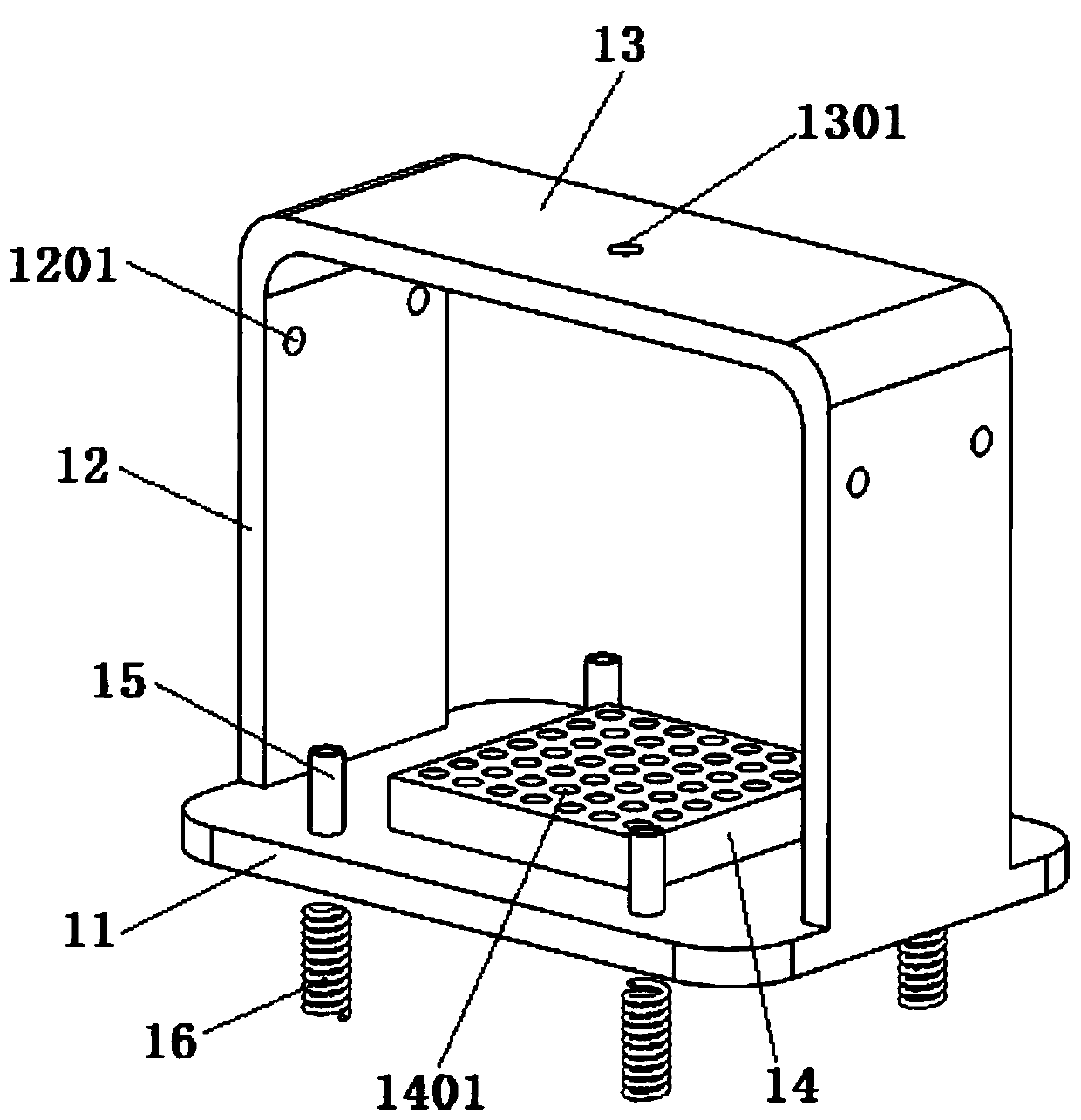

[0044] Such as figure 2 As shown, the bearing device 1 includes a bearing base plate 11, and universal wheels are...

Embodiment 1

[0053] A cultivation soil for improving the survival rate of safflower camellia seedlings, comprising the following raw materials in parts by weight: 80 parts of cultivation substrate, 0.8 part of perlite, 0.6 part of vermiculite, 7 parts of slow-release compound fertilizer, 0.1 part of quicklime powder, and compound hormone 0.05 copies;

[0054] This culture soil is made by following steps:

[0055] Step S1, weighing each raw material according to parts by weight;

[0056] Step S2, place each raw material on the loading plate 21 of the culture soil production device, turn on the motor connected to the first shaft 3101, and simultaneously turn on the steam connected to the steam storage box 14, and place each raw material in the culture soil production device Treat for 20min;

[0057] Step S3, turn off the motor and the steam source, and after the mixture on the loading plate 21 is cooled to normal temperature, discharge the mixture to prepare culture soil.

Embodiment 2

[0059] A cultivation soil for improving the survival rate of safflower camellia seedlings, comprising the following raw materials in parts by weight: 90 parts of cultivation substrate, 0.9 part of perlite, 0.7 part of vermiculite, 8 parts of slow-release compound fertilizer, 0.13 part of quicklime powder, compound hormone 0.07 copies;

[0060] This culture soil is made by following steps:

[0061] Step S1, weighing each raw material according to parts by weight;

[0062] Step S2, place each raw material on the loading plate 21 of the culture soil making device, turn on the motor connected to the first shaft 3101, and simultaneously turn on the steam connected to the steam storage box 14, and put each raw material in the culture soil making device Treat for 25 minutes;

[0063] Step S3, turn off the motor and the steam source, and after the mixture on the loading plate 21 is cooled to normal temperature, discharge the mixture to prepare culture soil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com