Additive, wax removal solvent and removal method for removing wax from tobacco leaves

A technology for additives and tobacco leaves, which is applied in the field of wax removal solvents and additives for removing and removing wax from tobacco leaves, and can solve problems such as low removal efficiency of dewaxing agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Crush the tobacco leaves to 100 mesh, transfer to the subcritical extraction kettle, then add butane and 0.1% cetyl alcohol triethoxyethylene ether accounting for the mass percentage of butane, the ratio of solid to liquid is 1:8, at 10°C Extract for 3 hours, and the extraction pressure is the saturated vapor pressure of butane at a temperature of 10°C. After the extraction, the dewaxed tobacco leaves are obtained, and the extract is evaporated under reduced pressure to obtain plant wax, wherein the yield of the plant wax is 1.5%.

Embodiment 2

[0040] Crush the tobacco leaves to 100 mesh, transfer to the subcritical extraction kettle, then add butane and tetradecyl alcohol pentaethoxylate accounting for 0.5% by mass percentage of butane, the ratio of solid to liquid is 1:10, at 5°C Extract for 4 hours, the extraction pressure is the saturated vapor pressure of butane at 5°C. After the extraction, the wax-removed tobacco leaves were obtained, and the extract was evaporated under reduced pressure to obtain plant wax, with a total extraction yield of 2.12%, of which the plant wax yield was 1.73%.

Embodiment 3

[0045] Crush the tobacco leaves to 10 mesh, transfer them to a subcritical extraction kettle, then add a butane solution containing 1% dodecyl alcohol trisoxyethylene ether, the ratio of solid to liquid is 1:12, and extract at 10°C for 1.5h , the extraction pressure is the saturated vapor pressure of butane at the temperature of 10°C. After the extraction, the dewaxed tobacco leaves are obtained, and the extract is evaporated under reduced pressure to obtain plant wax, wherein the yield of plant wax is 2.6%.

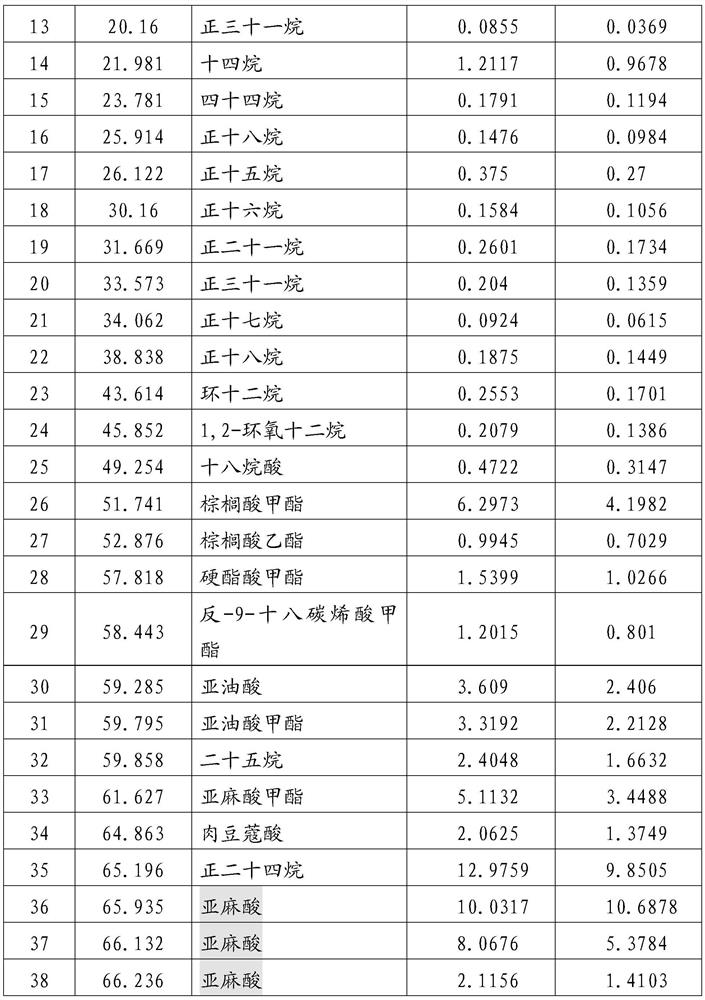

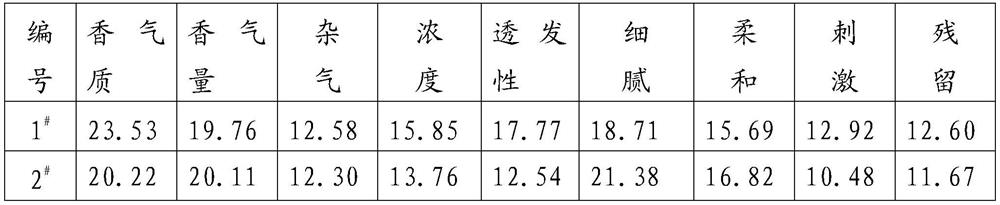

[0046] Tobacco extract was prepared from the dewaxed tobacco leaves after subcritical extraction by solvent extraction, using 50% ethanol as solvent, the ratio of solid to liquid was 1:10, and extracted at room temperature for 24 hours. After the extraction is completed, the extract is filtered and separated, and the extract is concentrated under reduced pressure until there is no alcohol, and the tobacco leaf extract 1 is obtained. # (Yield 19.52%). Using undewaxed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com