Electrocatalyst based on FeOOH-NiOOH/NF and preparation method of electrocatalyst

An electrocatalyst and iron oxyhydroxide technology, applied in the field of hydrogen energy, can solve the problems of unfavorable practical application and popularization of electrolyzed water, single catalytic activity, high price, etc., achieve excellent electrocatalytic oxygen evolution and hydrogen evolution performance, simple preparation method, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0037] (1) Treatment of nickel foam: Cut carbon cloth nickel foam into a size of 1x3 cm, then ultrasonically wash in 0.5 mol / L hydrochloric acid solution, deionized water, and ethanol for 5 minutes, cycle wash three times, and then dry it for later use.

[0038] (2) Prepare mixed solvent: Measure 8 mL sodium hydroxide (5 M), 4 mL ammonium persulfate (0.5 M) and 9 mL deionized water respectively, mix them, ultrasonicate for 10 minutes, mix well and set aside.

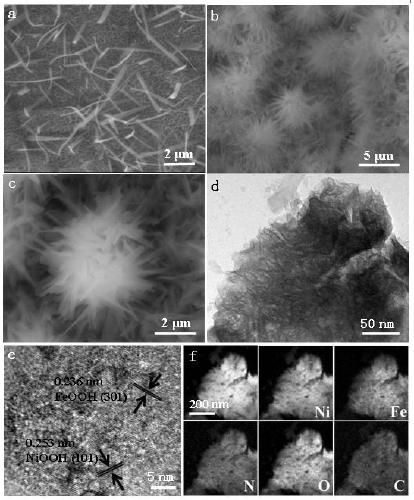

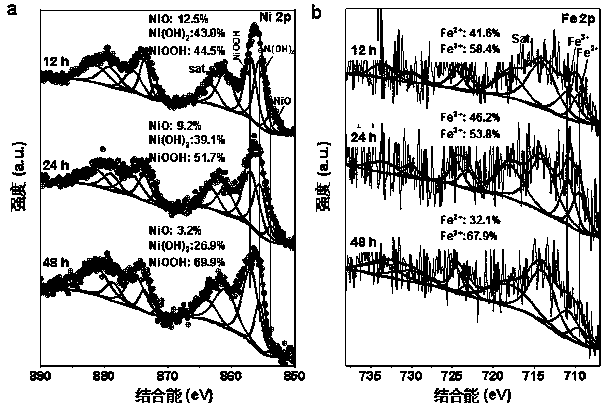

[0039] (3) Preparation of Ni(OH) 2 NTs / NF: Take 1*3 cm 2 The nickel foam was immersed in the prepared mixed solvent for 30 minutes at room temperature, then heated to 80 °C, kept for 12 h, and cooled to room temperature to obtain Ni(OH) 2 NTs / NF nanosheets (the nanosheets formed are Example 5).

[0040] (4) Preparation of nickel-iron mixed solution: take 30 mL of 0.2 M ferric chloride solution, and add sodium dodecylsulfonate (1 mL, 1 g L -1 ), ultrasonically mixed for 30 minutes, put the Ni(OH)2 NTs / NF nanosheets pre...

Embodiment 3

[0044] (1) Treatment of nickel foam: Cut carbon cloth nickel foam into a size of 1x3 cm, then ultrasonically wash in 0.5 mol / L hydrochloric acid solution, deionized water, and ethanol for 5 minutes, cycle wash three times, and then dry it for later use.

[0045] (2) Prepare mixed solvent: Measure 8 mL sodium hydroxide (5 M), 4 mL ammonium persulfate (0.5 M) and 9 mL deionized water respectively, mix them, ultrasonicate for 10 minutes, mix well and set aside.

[0046] (3) Preparation of Ni(OH) 2 NTs / NF: Take 1*3 cm 2 The nickel foam was immersed in the prepared mixed solvent for 30 minutes at room temperature, then heated to 80 °C, kept for 12 h, and cooled to room temperature to obtain Ni(OH) 2 NTs / NF nanosheets (the nanosheets formed are Example 5).

[0047] (4) Preparation of nickel-iron mixed solution: take 30 mL of 0.2 M ferric chloride solution, and add sodium dodecylsulfonate (1 mL, 1 g L -1 ), ultrasonically mixed for 30 minutes, put the Ni(OH)2 NTs / NF nanosheets p...

Embodiment 4

[0051] (1) Treatment of nickel foam: Cut carbon cloth nickel foam into a size of 1x3 cm, then ultrasonically wash in 0.5 mol / L hydrochloric acid solution, deionized water, and ethanol for 5 minutes, cycle wash three times, and then dry it for later use.

[0052] (2) Prepare mixed solvent: Measure 8 mL sodium hydroxide (5 M), 4 mL ammonium persulfate (0.5 M) and 9 mL deionized water respectively, mix them, ultrasonicate for 10 minutes, mix well and set aside.

[0053] (3) Preparation of Ni(OH) 2 NTs / NF: Take 1*3 cm 2 The nickel foam was immersed in the prepared mixed solvent for 30 minutes at room temperature, then heated to 80 °C, kept for 12 h, and cooled to room temperature to obtain Ni(OH) 2 NTs / NF nanosheets (the nanosheets formed are Example 5).

[0054] (4) Preparation of nickel-iron mixed solution: take 30 mL of 0.2 M ferric chloride solution, and add sodium dodecylsulfonate (1 mL, 1 g L -1 ), ultrasonically mixed for 30 minutes, put the Ni(OH)2 NTs / NF nanosheets p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com