Method for preparing palladium single-atom double-active-site full-hydrolysis catalyst

A hydrolysis catalyst and dual-activity technology, applied in chemical instruments and methods, physical/chemical process catalysts, oxygen preparation, etc., can solve the problems of single-atom single function, difficult to use, difficult single-atom reactive active sites, etc., to achieve Novel shape, high product purity and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

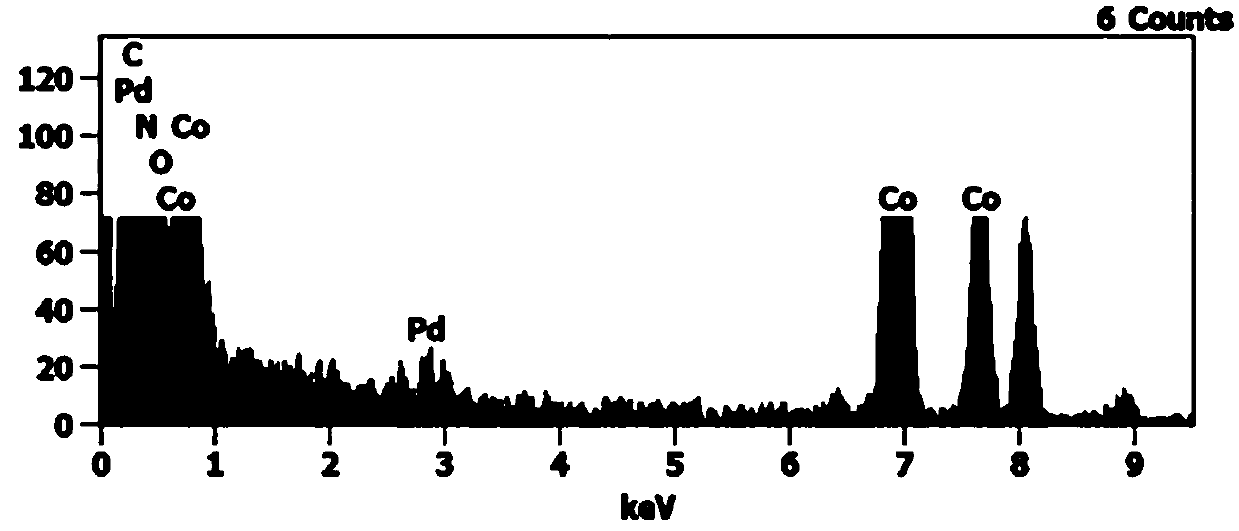

[0024] The invention provides a method for preparing an iridium monoatomic double active site full hydrolysis catalyst, the method uses a metal organic framework structure ZIF-67 as a carrier, ethanol as a solvent, and C 10 h 14 o 4 Pd is evenly mixed, suction filtered, dried, and calcined to form a two-site full hydrolysis catalyst in which single-atom Pd is uniformly dispersed on nitrogen-doped carbon and metal cobalt, and the specific operation steps are as follows:

[0025] At room temperature, disperse 99.5g metal-organic framework structure ZIF-67 in 100% ethanol for 60 minutes, and then filter it on the filter membrane; dry the filtered ZIF-67 and the filter membrane together, and the drying temperature is 80 ℃; put 0.5gC 10 h 14 o 4 Dissolve Pd in 0.5L of 100% ethanol, and ultrasonically disperse for 30 minutes; soak the dried filter membrane in the above C 10 h 14 o 4 Put in the Pd solution for 10 minutes, then take it out, continue drying, the drying tempera...

Embodiment 2

[0028] The invention provides a method for preparing an iridium monoatomic double active site full hydrolysis catalyst, the method uses a metal organic framework structure ZIF-67 as a carrier, ethanol as a solvent, and C 10 h 14 o 4 Pd is evenly mixed, suction filtered, dried, and calcined to form a two-site full hydrolysis catalyst in which single-atom Pd is uniformly dispersed on nitrogen-doped carbon and metal cobalt, and the specific operation steps are as follows:

[0029] At room temperature, disperse 99g of metal-organic framework structure ZIF-67 in 100% ethanol for 60 minutes, and then filter it on the filter membrane; dry the filtered ZIF-67 and the filter membrane together, and the drying temperature is 80°C ; put 1gC 10 h 14 o 4 Dissolve Pd in 1L of 96% ethanol, and ultrasonically disperse for 30 minutes; soak the dried filter membrane in the above C 10 h 14 o 4 Put in the Pd solution for 10 minutes, then take it out, continue drying, the drying temperatur...

Embodiment 3

[0031] The invention provides a method for preparing an iridium monoatomic double active site full hydrolysis catalyst. The method uses a metal organic framework structure ZIF-67 as a carrier, ethanol as a solvent, and C 10 h 14 o 4 Pd is uniformly mixed, suction filtered, dried, and calcined to form a two-site full hydrolysis catalyst in which single-atom Pd is uniformly dispersed on nitrogen-doped carbon and metal cobalt, and the specific operation steps are as follows:

[0032] At room temperature, disperse 99g of metal-organic framework structure ZIF-67 in 100% ethanol for 60 minutes, and then filter it on the filter membrane; dry the filtered ZIF-67 and the filter membrane together, and the drying temperature is 80°C ; put 1gC 10 h 14 o 4 Dissolve Pd in 1L of 100% ethanol, and ultrasonically disperse for 30 minutes; soak the dried filter membrane in the above C 10 h 14 o 4 Put in the Pd solution for 10 minutes, then take it out, continue drying, the drying temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com