Regeneration process of working solution in hydrogen peroxide production process by anthraquinone method

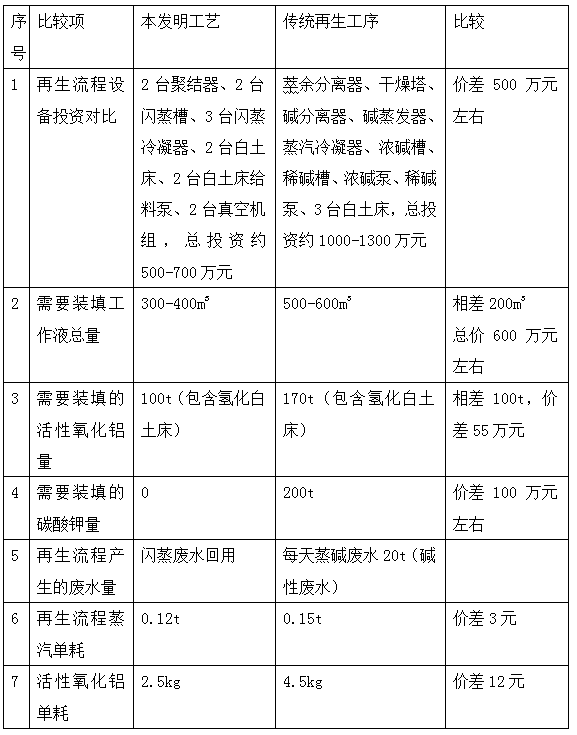

A technology of working fluid and hydrogen peroxide, applied in peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, chemical instruments and methods, inorganic chemistry, etc. High consumption of aluminum, large volume and other problems, to achieve the effect of less activated alumina, extended service life, and small design volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] 1. Regeneration process:

[0040] 1. Analyze the components from the extraction tower:

[0041] In addition to the normal working fluid components (heavy aromatics, trioctyl phosphate, tetrabutylurea, 2-ethylanthraquinone, 2-ethyltetrahydroanthraquinone), the raffinate also contains 0.47wt% water, Hydrogen peroxide 0.02wt%, hydrogenated anthraquinone degradation products and epoxy anthraquinone degradation products.

[0042] 2. Coalesce and separate the above raffinate by using a raffinate coalescer:

[0043] The raffinate coalescer is mainly composed of a hydrophobic-based filter element. When the free water in the extract contacts the hydrophobic-based filter element, the free water is not easy to pass through, so that the free water gradually gathers in the hydrophobic-based filter element. The large water droplets sink to the bottom of the filter element of the coalescer and are discharged to the bottom of the coalescer through the drainage layer.

[0044] After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com