An electrodialysis device for resource utilization of high-salt wastewater from mustard pickling

A technology of high-salt wastewater and electrodialysis, which is applied in the direction of food industry wastewater treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high use cost, high energy consumption, easy corrosion of equipment, etc., and improve the service life , Improve the removal efficiency and prolong the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

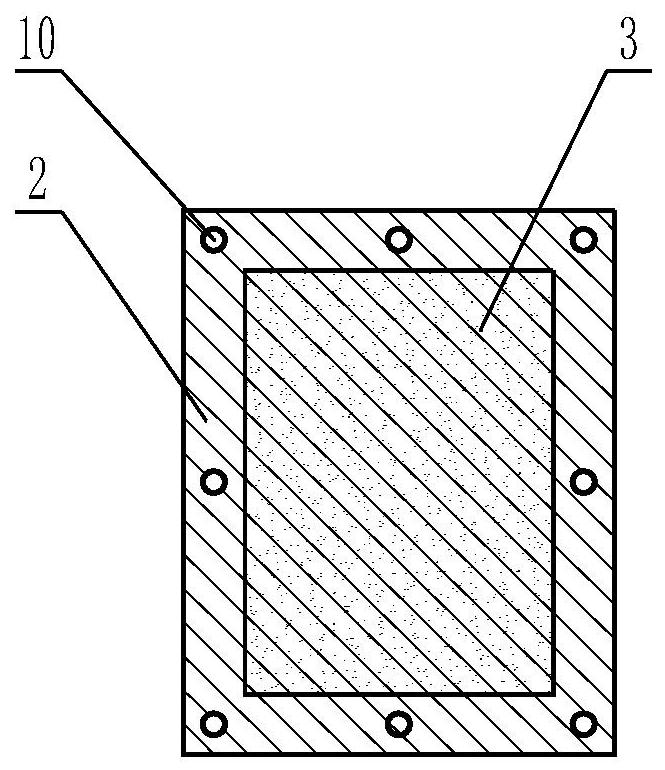

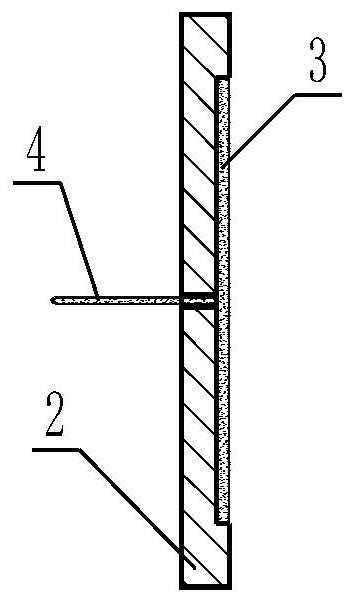

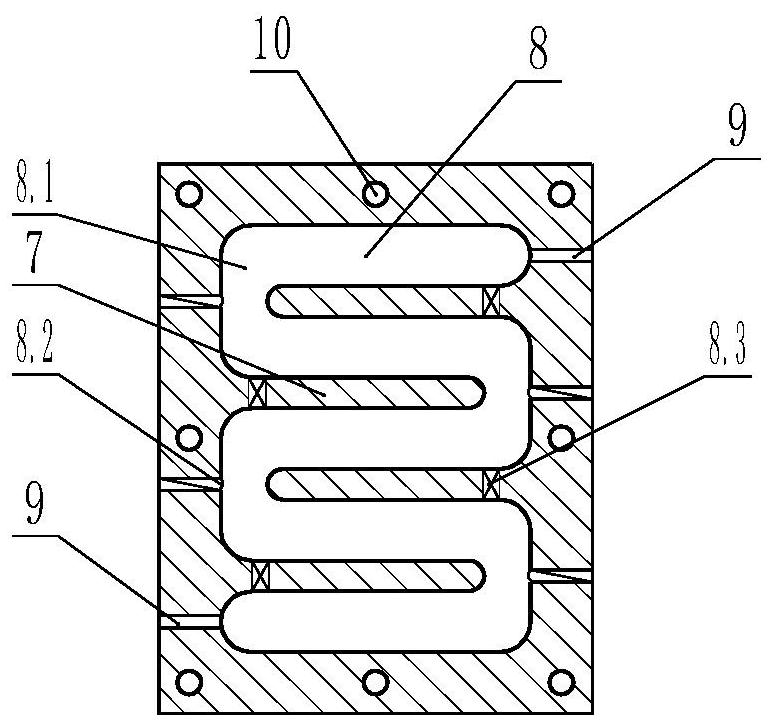

[0031] Such as Figure 1-Figure 5 As shown, this embodiment provides an electrodialysis device for resource utilization of mustard pickled high-salt wastewater, including an electrodialysis reactor 1, and the electrodialysis reactor 1 includes two end plate assemblies and is located between the two end plate assemblies. The membrane stack, the end plate assembly includes an end plate 2 and an electrode plate 3 embedded in the end plate 2, an electrode column 4 is fixed on the end plate 2, and the electrode plate 3 is connected to an external power supply through the electrode column 4 respectively; The stack includes a bipolar membrane 3.1, a cationic membrane 6, an anionic membrane 5 and a bipolar membrane 3.1 arranged in sequence, and the above membranes are placed between the cathode and the anode, between two adjacent membranes, and between the electrode plate 3 and the membrane. Separated by the partition plate 7, the partition plate 7 is provided with a bent flow channel...

Embodiment 2

[0034] This embodiment is optimized and defined on the basis of the above-mentioned embodiment 1.

[0035] In order to realize the sealed connection of the structure, the end plate 2 and the partition plate 7 are provided with one-to-one corresponding bolt holes 10 in the circumferential direction, and the end plate assembly and the membrane stack are tightly connected by bolts passing through the bolt holes 10 .

Embodiment 3

[0037] This embodiment is optimized and defined on the basis of the above-mentioned embodiment 1.

[0038] In order to prolong the circulation time of the source water in the electrodialysis reactor 1, the flow channel 8 has a "bow"-shaped structure, and the partition plate 7 at the "bow"-shaped corner of the flow channel is installed with elastic holes 8.3 connected to the bent flow channel , the elastic hole is composed of a communicating hole on the separator and a perforated elastic membrane that blocks the communicating hole. Such a structure can change the size and angle of the elastic hole 8.3 by changing the flow rate or pressure of the water in the flow channel. At the corner position Multi-angle scour is formed to avoid deposition and clogging. The elastic pores 8.3 are preferably small micropores less than 0.1 mm at normal flow rates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com