A printing and dyeing wastewater membrane treatment and reuse process

A technology for printing and dyeing wastewater and membrane treatment, which is used in textile industry wastewater treatment, water/sewage treatment, water treatment parameter control, etc. The effect of small footprint, increased contact area, and extended processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

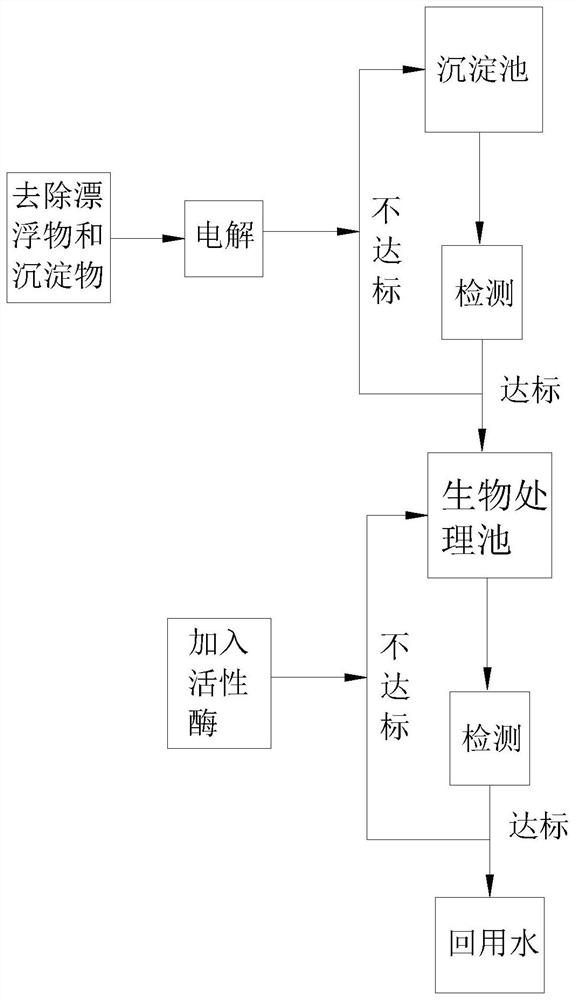

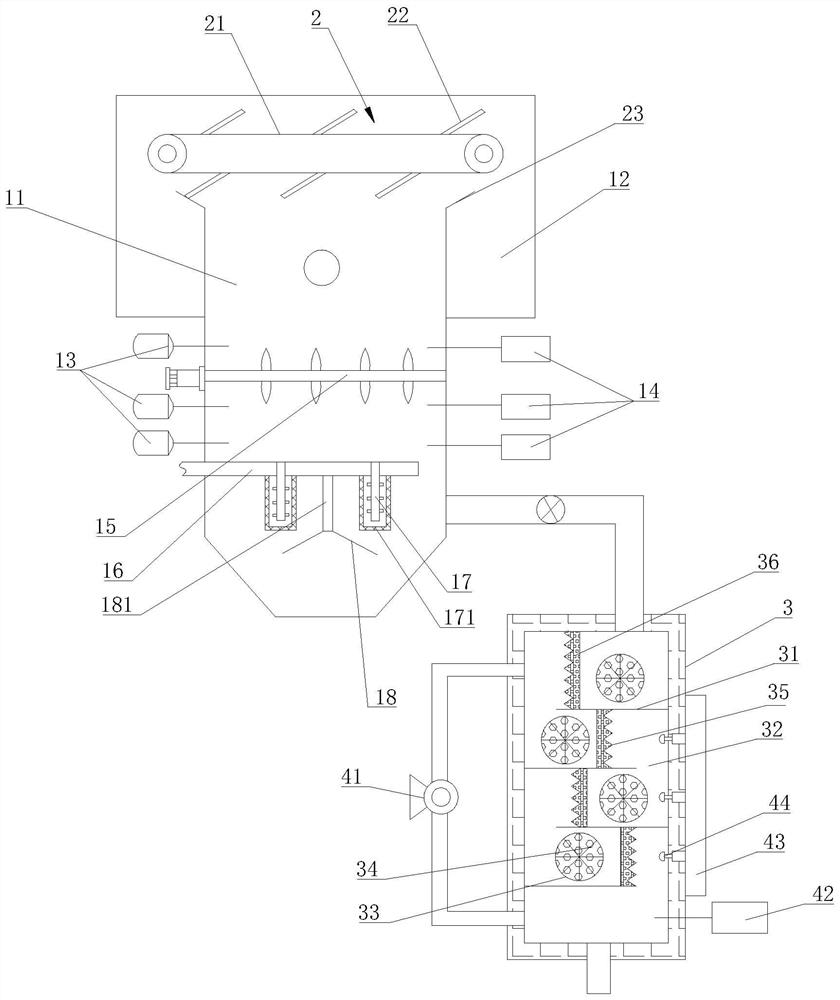

[0032] Such as figure 1 with 2 Shown, a printing and dyeing wastewater membrane treatment and recycling process is characterized in that: comprising the following steps:

[0033] a. Introduce waste water into the sedimentation tank, add different medicines into the sedimentation tank through several medicine tanks, stir, and let it stand for 20-30 minutes, decolorize the waste water, precipitate impurities and neutralize, and obtain product A; the medicines include decolorizers , Precipitating agent and neutralizing agent.

[0034] b. Pass the micro-bubbles into product A through the air-bubble inlet tube, stir, the micro-bubbles capture and absorb the suspended matter in product A, make the suspended matter float up, remove SS and grease pollutants, and after standing for 10-30min, get The clarified liquid is product B;

[0035] c. Take product B and test it separately through several detectors. If the test results are all up to standard, it is product C; Enter direct cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com