B-site vacancy Fe-doped strontium titanate and preparation method thereof

A strontium titanate and vacancy technology, which is applied in the field of B-site vacancy Fe-doped strontium titanate and its preparation, can solve problems such as poor electrical conductivity and catalytic activity, achieve low cost, improve ionic conductivity, and improve particle size. Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

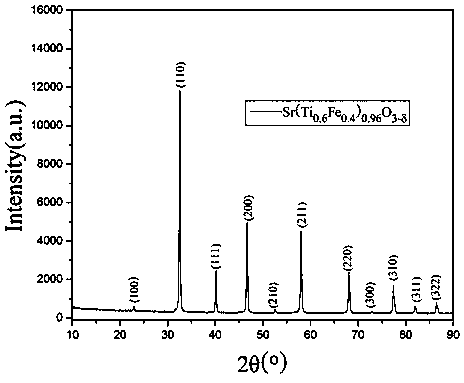

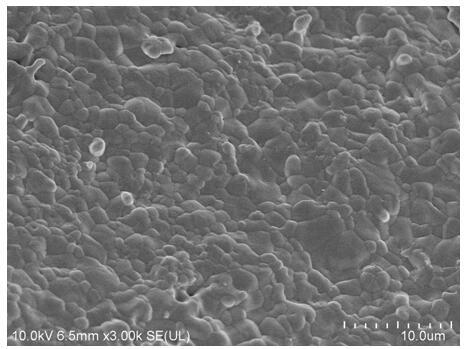

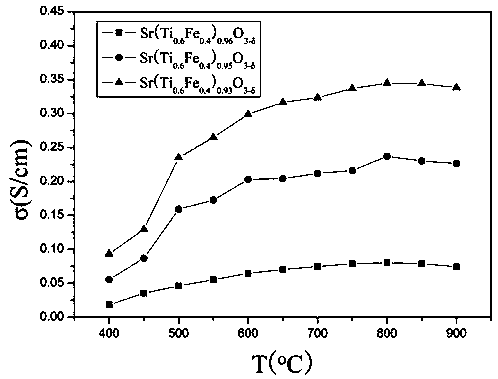

[0023] The B site vacancy Fe doped strontium titanate, the molecular formula is Sr(Ti 0.6 Fe 0.4 ) 1-x O 3-δ , The amount of vacancy in position B is x , A / B>1, where A is Sr, B is Ti and Fe; the amount of B site vacancy x Is 0.04.

[0024] The method for preparing Fe-doped strontium titanate with B-site vacancy includes the following steps:

[0025] Step 1. Use sol-gel method to synthesize precursor powder:

[0026] 1.0286g of strontium acetate was dissolved in 4mL of deionized water, 0.1533g of iron oxide and 0.9801g of tetrabutyl titanate were dissolved in 34mL of isopropanol and 4mL of absolute ethanol, and stirred on a magnetic stirrer for 40 minutes to form a sol; Leave it for 12 hours to form a wet gel in layers; put it in a drying box and dry it at 60°C to form a fluffy dry gel, and then grind to obtain a precursor powder;

[0027] Step 2. The precursor powder obtained in step 1 was calcined at 1100°C for 10 hours to obtain Fe-doped strontium titanate powder (Sr(Ti 0.6 Fe 0.4 ...

Embodiment 2

[0032] The B site vacancy Fe doped strontium titanate, the molecular formula is Sr(Ti 0.6 Fe 0.4 ) 1-x O 3-δ , The amount of vacancy in position B is x , A / B>1, where A is Sr, B is Ti and Fe; the amount of B site vacancy x Is 0.05.

[0033] The method for preparing Fe-doped strontium titanate with B-site vacancy includes the following steps:

[0034] Step 1. Use sol-gel method to synthesize precursor powder:

[0035] 1.0286g of strontium acetate was dissolved in 4mL of deionized water, 0.1517g of iron oxide and 0.9699g of tetrabutyl titanate were dissolved in 34mL of isopropanol and 4mL of absolute ethanol, and stirred on a magnetic stirrer for 40 minutes to form a sol; Leave it for 12 hours to form a wet gel in layers; put it in a drying box and dry it at 60°C to form a fluffy dry gel, and then grind to obtain a precursor powder;

[0036] Step 2. The precursor powder obtained in step 1 was calcined at 1100°C for 10 hours to obtain Fe-doped strontium titanate powder (Sr(Ti 0.6 Fe 0.4 ...

Embodiment 3

[0040] The B site vacancy Fe doped strontium titanate, the molecular formula is Sr(Ti 0.6 Fe 0.4 ) 1-x O 3-δ , The amount of vacancy in position B is x , A / B>1, where A is Sr, B is Ti and Fe; the amount of B site vacancy x Is 0.07.

[0041] The method for preparing Fe-doped strontium titanate with B-site vacancy includes the following steps:

[0042] Step 1. Use sol-gel method to synthesize precursor powder:

[0043] 1.0286g of strontium acetate was dissolved in 4mL of deionized water, 0.1485g of iron oxide and 0.9495g of tetrabutyl titanate were dissolved in 34mL of isopropanol and 4mL of absolute ethanol, and stirred on a magnetic stirrer for 40 minutes to form a sol; Leave it for 12 hours to form a wet gel in layers; put it in a drying box and dry it at 60°C to form a fluffy dry gel, and then grind to obtain a precursor powder;

[0044] Step 2. The precursor powder obtained in step 1 was calcined at 1100°C for 10 hours to obtain Fe-doped strontium titanate powder (Sr(Ti 0.6 Fe 0.4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com