Amino acid liquid fertilizer and preparation method thereof

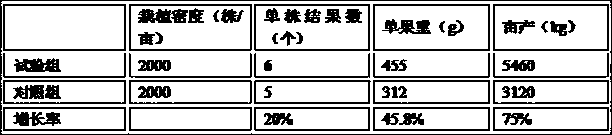

An amino acid and liquid fertilizer technology, applied in the field of fertilizers, can solve the problems of high cost that are not suitable for large-scale production of amino acid liquid fertilizers and amino acid liquid fertilizers, and achieve the effects of protecting the environment and effective utilization of resources, enriching amino acid content, and improving yield and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of amino acid liquid fertilizer provided by the invention comprises the following steps:

[0031] 1) 10-30 parts of shredded animal fur, 30-50 parts of fish product waste, 50-80 parts of crushed soybean by-products, 50-80 parts of animal manure, and 20-30 parts of activated sludge Mix to obtain the first mixture; wherein animal fur is selected from one or more of chicken feathers, duck feathers, goose feathers, and wool; fish product waste is selected from fish heads, fish steaks, fish skins, fish viscera, fish gills, fish One or more of fins and fish scales; one or more of bean dregs, bean cakes, and soybean meal by-products of soybean products; one or more of animal manure selected from chicken manure, pig manure, sheep manure, and cow manure Various; when crushing the by-products of soybean products, crush them until they pass through a 200-300 mesh sieve.

[0032] 2) Add 200-300 parts of water to the first mixture in step 1), and carry out an...

Embodiment 1

[0040] 1) Cut 10 parts of animal skins (chicken feather: goose feather = 1:1), 30 parts of fish product waste, 50 parts of bean dregs that have passed through a 200-mesh sieve, and 50 parts of animal manure (chicken manure: pig manure = 1:1) and 20 parts of activated sludge were mixed to obtain the first mixture;

[0041] 2) Add 200 parts of water to the first mixture in step 1), stir and mix well, place in a fermenter for anaerobic fermentation treatment, anaerobic fermentation at 40° C. for 40 days, and obtain the first fermentation product after the fermentation;

[0042] 3) The first fermentation product obtained in step 2) is subjected to ultrasonic treatment and oxidation, wherein the power of the ultrasonic treatment is 100W, and the ultrasonic treatment time is 30min; the oxidation is carried out by using ozone to oxidize and stir at the same time, wherein the introduction rate of ozone is: 100mg / h, the oxidation time is 30min, the stirring speed is 180r / min; the oxida...

Embodiment 2

[0046] 1) Cut 30 parts of animal skins (chicken feather: goose feather = 1:1), 50 parts of fish product waste, 80 parts of bean dregs that have passed through a 300-mesh sieve, and 80 parts of animal manure (chicken manure: pig manure = 1:1) and 30 parts of activated sludge were mixed to obtain the first mixture;

[0047] 2) Add 300 parts of water to the first mixture in step 1), stir and mix well, place in a fermenter for anaerobic fermentation treatment, anaerobic fermentation at 50° C. for 30 days, and obtain the first fermentation product after the fermentation;

[0048] 3) The first fermentation product obtained in step 2) is subjected to ultrasonic treatment and oxidation, wherein the power of the ultrasonic treatment is 150W, and the ultrasonic treatment time is 20min; the oxidation is carried out by using ozone to oxidize and stir at the same time, wherein the introduction rate of ozone is: 150mg / h, the oxidation time is 20min, the stirring speed is 240r / min; the oxida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com