Application of double perovskite nanocrystalline material in preparation of inorganic white light LED

A technology of nanocrystalline material and double perovskite, applied in nano optics, luminescent materials, nanotechnology, etc., can solve the problems of low color rendering index and low luminous efficiency of white LED

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

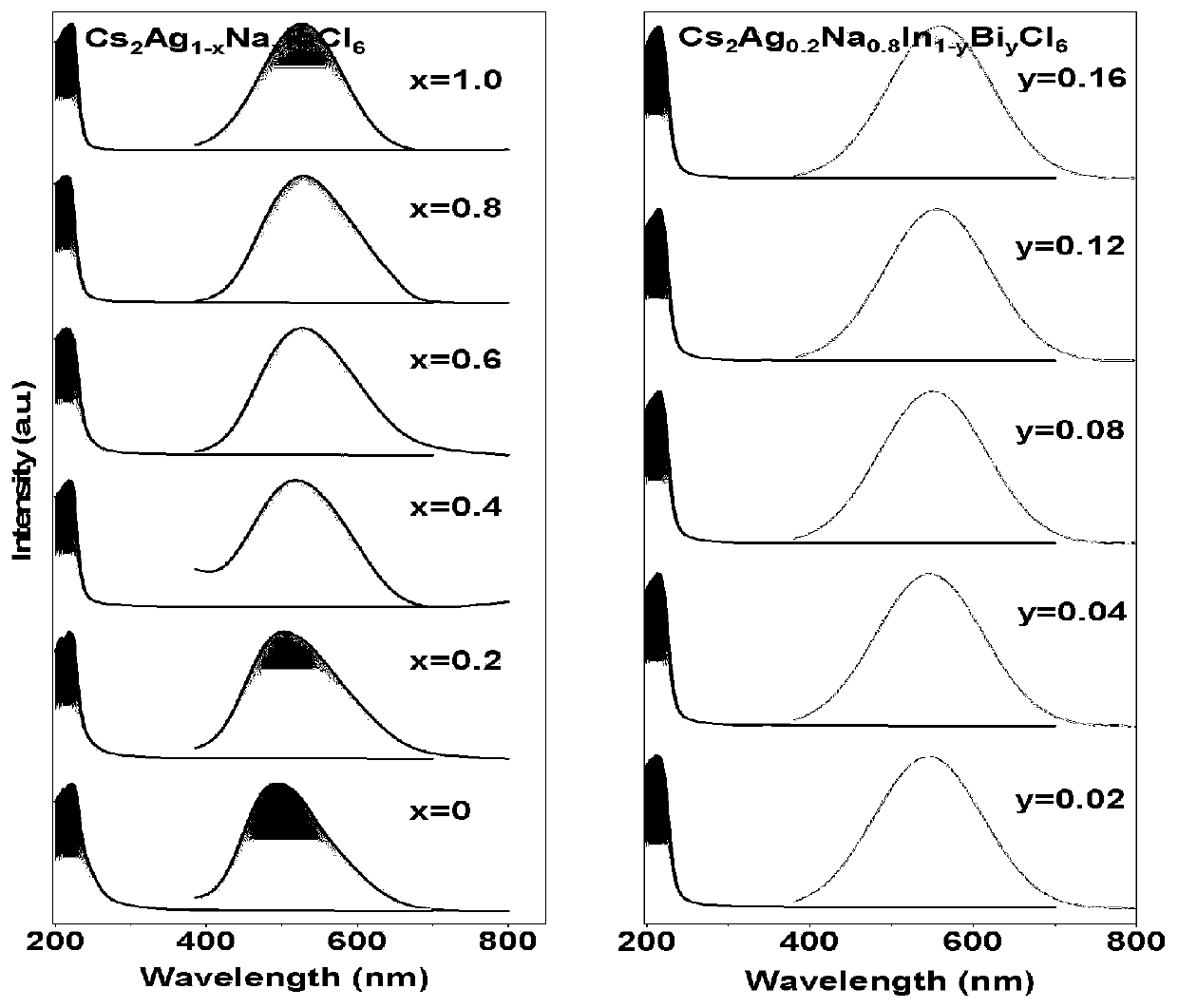

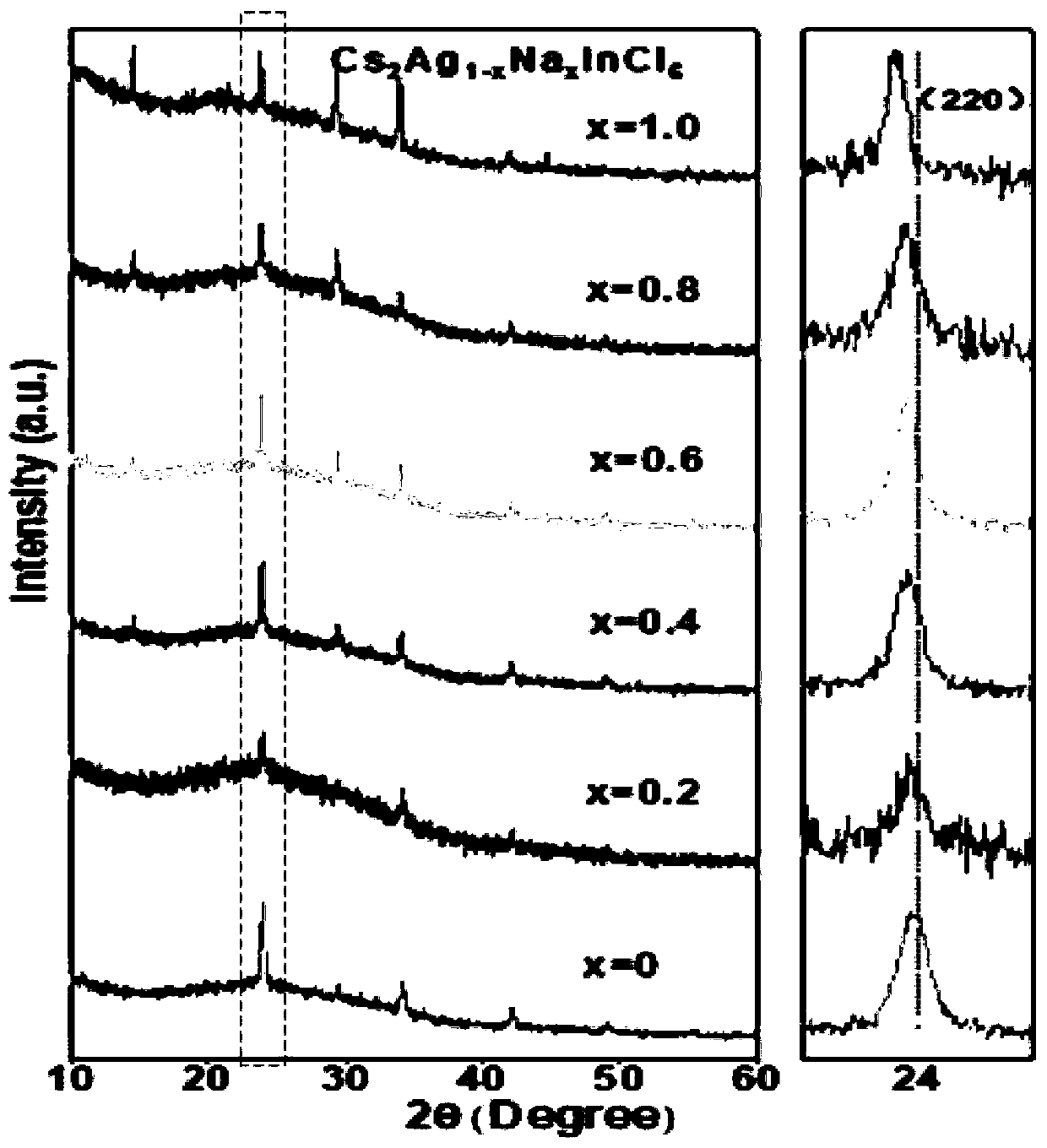

Method used

Image

Examples

Embodiment 1

[0063] Cs 2 AgInCl 6 Preparation of Nanocrystals. The preparation method is as follows:

[0064] Weigh 0.2mmol cesium chloride (CsCl), 0.1mmol silver chloride (AgCl) and .01mmol indium chloride (InCl) 3 ), the purity of the above raw materials is more than 99.9%. The weighed above-mentioned raw materials were poured into a 25ml sample bottle, and then 10ml DMSO was added. Put the sample vial in a sand bath and heat and stir at 80°C to dissolve. After it is completely dissolved, turn off the heating and stirring, take out the sample bottle, and reserve the precursor solution for later use. Use a pipette gun to take 100 microliters of the precursor solution and inject it into 5ml of isopropanol, and stir vigorously for 5 minutes to end the reaction. The reaction solution was centrifuged at 5000 rpm for 10 min, the bottom precipitate was discarded, and the supernatant was set aside.

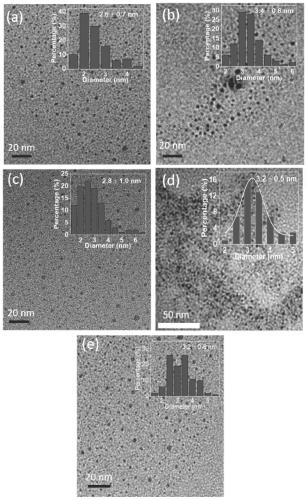

[0065] The average particle size of the perovskite nanocrystals prepared in this example ...

Embodiment 2

[0067] Cs 2 NaInCl 6 Preparation of Nanocrystals. The preparation method is as follows:

[0068] Weigh 0.2mmol cesium chloride (CsCl), 0.1mmol sodium chloride (NaCl) and 0.1mmol indium chloride (InCl) respectively 3 ), the purity of the above raw materials is more than 99.9%. The weighed above-mentioned raw materials were poured into a 25ml sample bottle, and then 10ml DMSO was added. Put the sample vial in a sand bath and heat and stir at 120°C to dissolve. After it is completely dissolved, turn off the heating and stirring, take out the sample bottle, and reserve the precursor solution for later use. Use a pipette gun to take 100 microliters of the precursor solution and inject it into 5ml of isopropanol, and stir vigorously for 3 minutes to end the reaction. The reaction solution was centrifuged at 5000 rpm for 5 min, the bottom precipitate was discarded, and the supernatant was set aside.

[0069] The average particle size of the perovskite nanocrystals prepared in ...

Embodiment 3

[0071] Cs 2 Ag 0.8 Na 0.2 InCl 6 Preparation of Nanocrystals. The preparation method is as follows:

[0072] Weigh and weigh 0.2mmol cesium chloride (CsCl), 0.08mmol silver chloride (AgCl), 0.02mmol sodium chloride (NaCl) and 0.1mmol indium chloride (InCl) respectively. 3 ), the purity of the above raw materials is more than 99.9%. The weighed above-mentioned raw materials were poured into a 25ml sample bottle, and then 10ml DMSO was added. Put the sample vial in a sand bath and heat and stir at 80°C to dissolve. After it is completely dissolved, turn off the heating and stirring, take out the sample bottle, and reserve the precursor solution for later use. Use a pipette gun to take 100 microliters of the precursor solution and inject it into 5ml of isopropanol, and stir vigorously for 5 minutes to end the reaction. The reaction solution was centrifuged at 5000 rpm for 10 min, the bottom precipitate was discarded, and the supernatant was set aside.

[0073] The averag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com