Polyoxymethylene dimethyl ether synthesis and separation system

A polyoxymethylene dimethyl ether and separation system technology, applied in the direction of distillation separation, separation method, fractionation, etc., can solve the problems of high production investment cost, low synthesis conversion rate and yield, etc., and achieve efficient use of energy, energy The effect of reducing consumption and reducing the amount of formic acid easily disproportionated at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

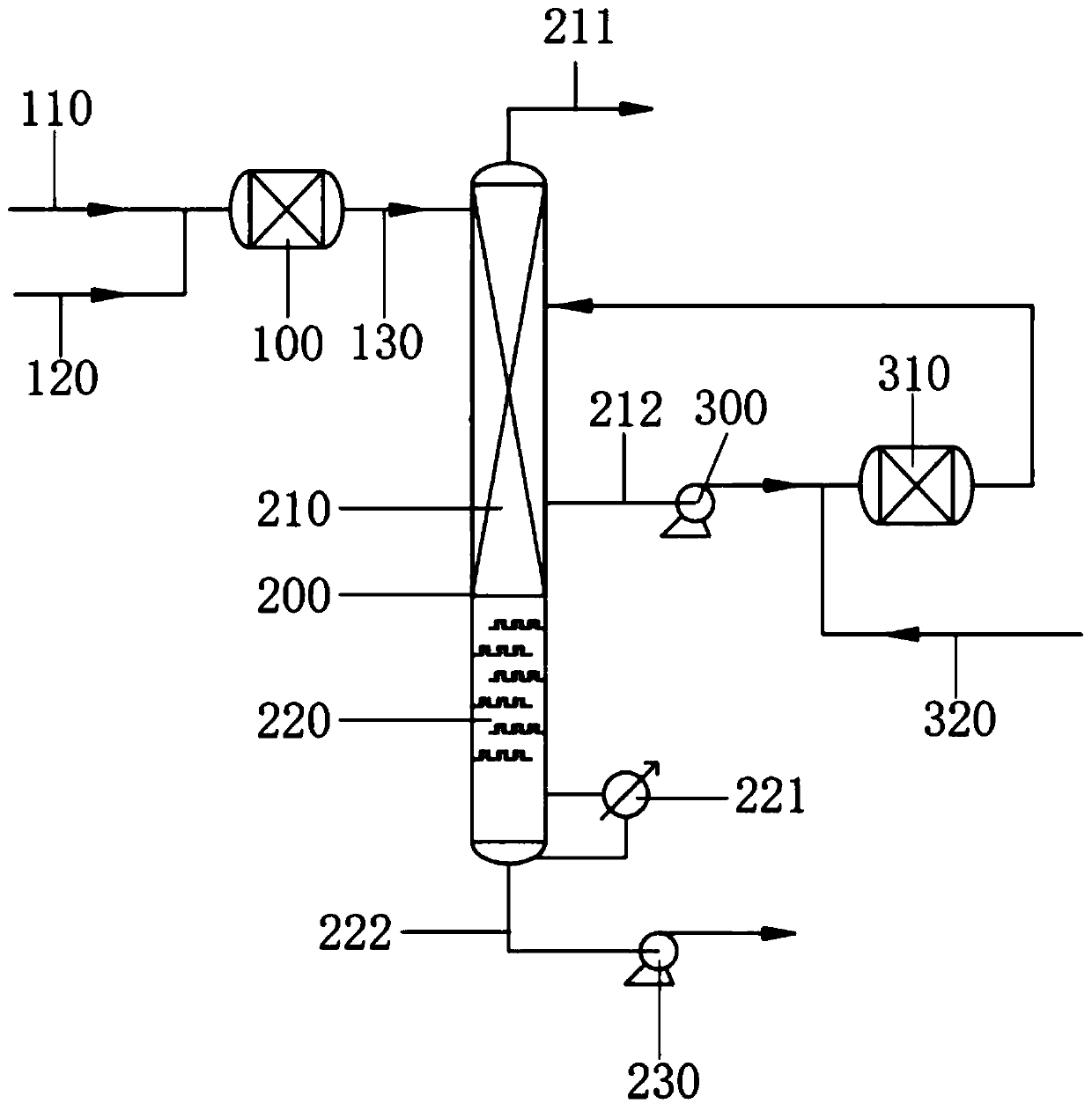

[0032] The high-concentration formaldehyde with a mass concentration of 81% and the methylal stream with a mass concentration of 92% are pumped to the pre-reactor 100 through the formaldehyde pipe 110 and the methylal pipe 120 respectively, and reacted in the pre-reactor 100 to obtain a crude reaction liquid , And discharged through the crude reaction liquid pipe 130, preheated to 80 ℃ high-concentration formaldehyde and heated and pressurized methylal, temperature 60 ℃, pressure 0.2Mpa, the mass ratio of formaldehyde to methylal in the reactant is 1 :1;

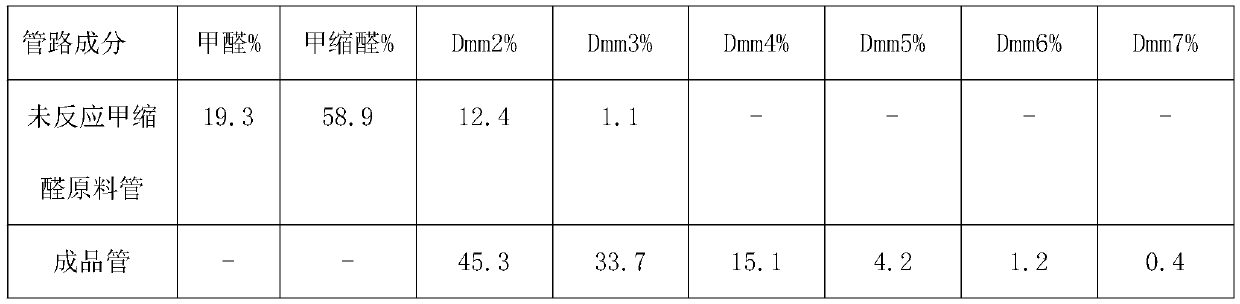

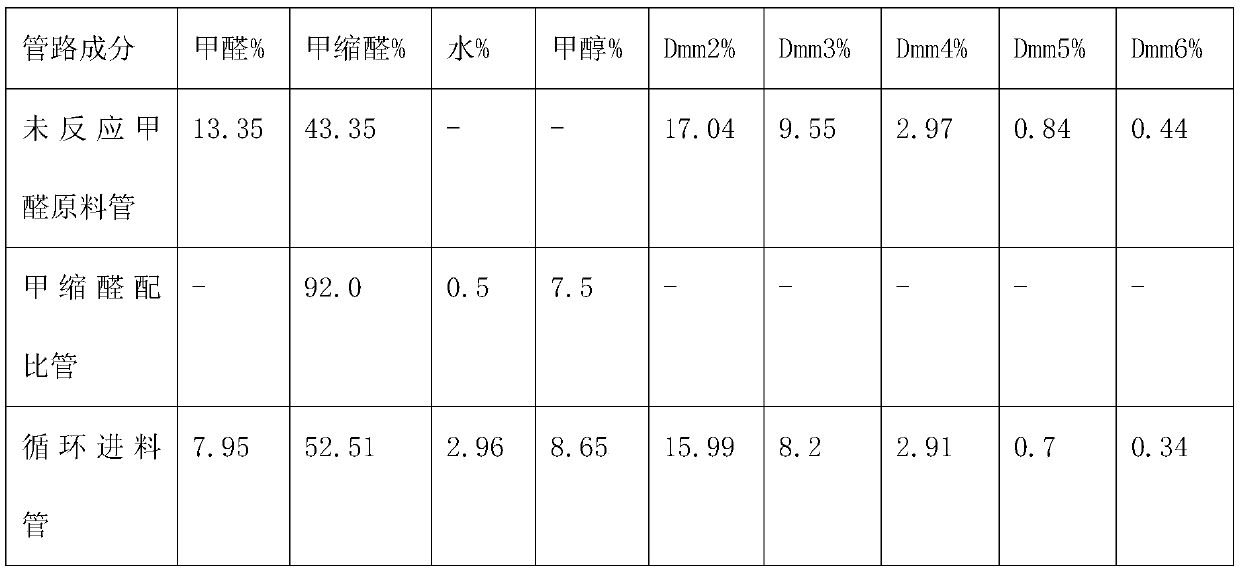

[0033] Pipeline composition formaldehyde% water% Methanol% Methylal% Dmm2-8% Formaldehyde tube81%18.01.0-- Methylal tube920.57.5-- Coarse reaction liquid tube 20.254.885.8869.0-

[0034] After reacting in the pre-reactor 100, it can be seen that the water conversion rate is about 20%, the methylal conversion rate is 30.7%, and the formaldehyde conversion rate is 17.1%. A large amount of water is converted, and the water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com