Facultative MBR sewage treatment tank, facultative MBR sewage treatment device and facultative MBR sewage treatment method

A technology for sewage treatment equipment and sewage treatment pools, applied in water/sewage treatment equipment, water/sewage treatment, biological water/sewage treatment, etc., can solve the problems of high energy consumption, easy membrane pollution, dissolved oxygen, etc. Reduced run time, reduced membrane fouling, reduced oxygen levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

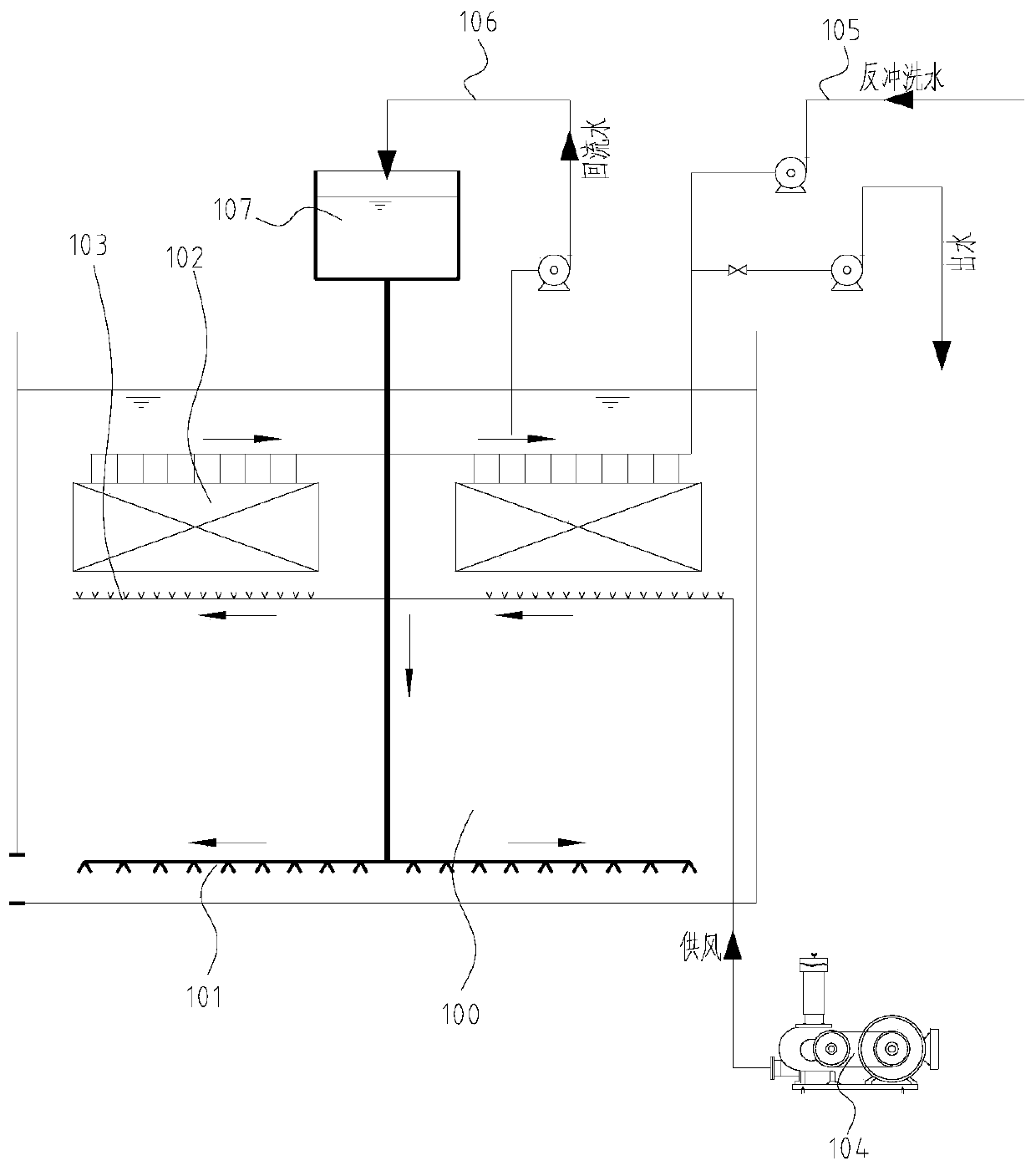

[0036] In order to solve the technical problems that the traditional aerobic MBR process is used in the treatment of lightly polluted wastewater, the dissolved oxygen is too high, the energy consumption is high, and the membrane fouling is easy to occur due to excessive aeration. Embodiment 1 of the present invention provides a kind of facultative type MBR sewage treatment pond 100, and it comprises the water inlet zone, mixed reaction zone, membrane separation water outlet zone that are arranged from bottom to top, specifically,

[0037] The water inlet of the water inlet area is provided with a filter screen 301 for pre-filtering impurities in the sewage, such as figure 1 As shown, the bottom of the water inlet area is provided with a water distribution pipe 101, and a plurality of upward water distribution holes are evenly distributed on the water distribution pipe 101, and are connected to the pulse generator through a connecting pipe; The generator is set above the aerobi...

Embodiment 2

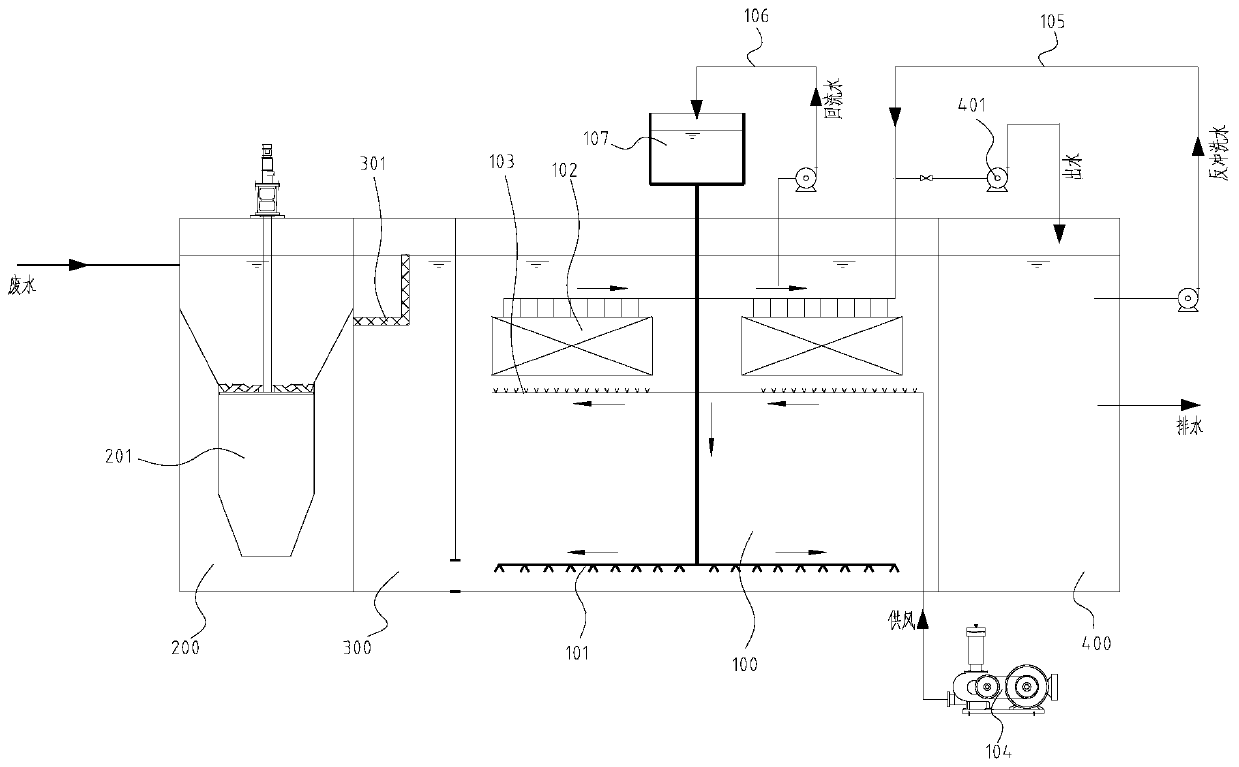

[0043] In order to solve the technical problems that the traditional aerobic MBR process is used in the treatment of lightly polluted wastewater, the dissolved oxygen is too high, the energy consumption is high, and the membrane fouling is easy to occur due to excessive aeration. Embodiment 2 of the present invention provides an aerobic type MBR sewage treatment equipment, which includes a swirl grit chamber 200, a water distribution pool 300, an aerobic MBR sewage treatment pool 100 and a clear water pool 400 connected in sequence; specifically,

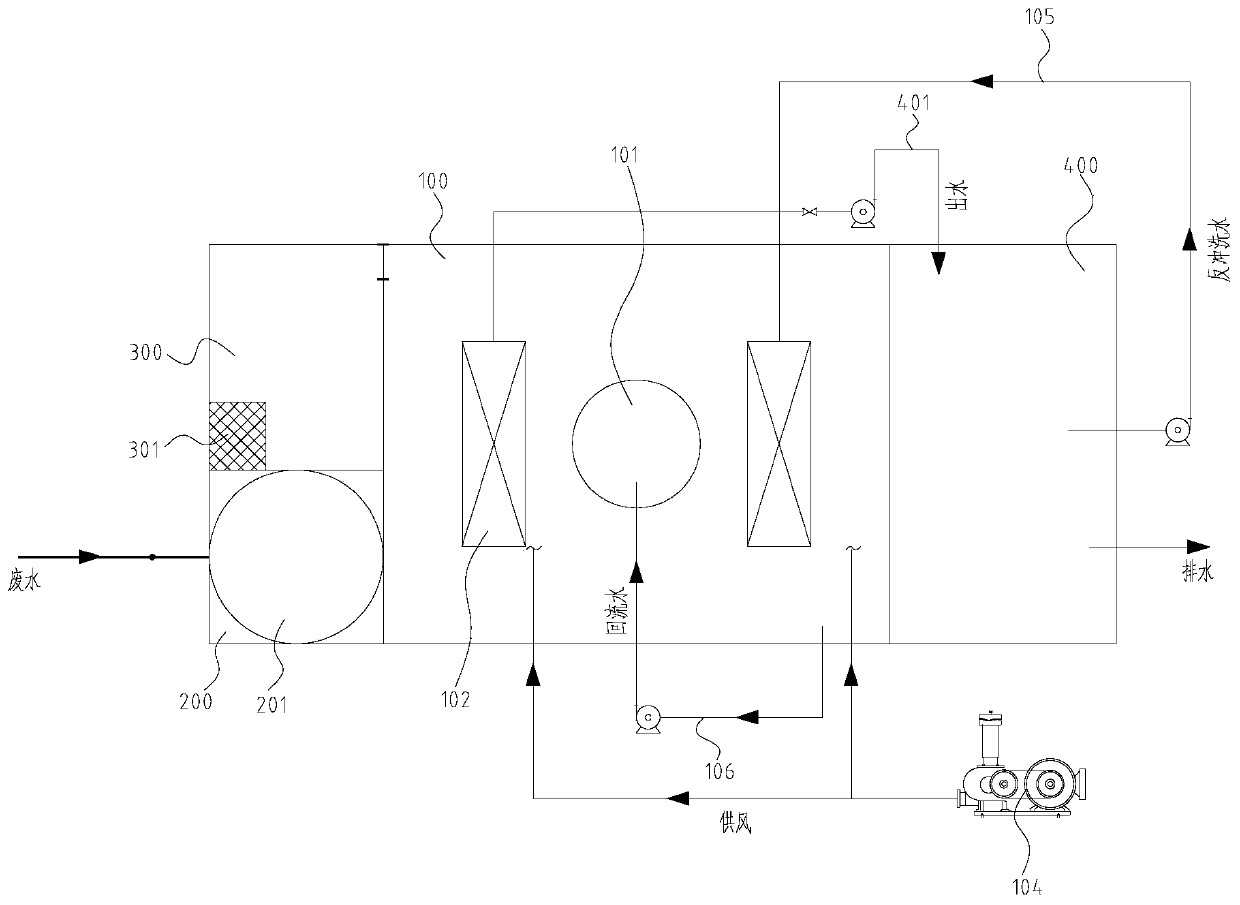

[0044] like figure 2 and image 3 As shown, the cyclone desander 201 is installed in the cyclone desander 200, and the sewage is pretreated through the cyclone desander 201, which can remove hard particles in the water; the cyclone desander The rotational speed of the stirrer in 201 is preferably 12-20 r / min.

[0045] like figure 2 and image 3 As shown, the water inlet of the water distribution pool 300 is arranged at the upp...

Embodiment 3

[0053] In order to solve the technical problems that the traditional aerobic MBR process is used in the treatment of lightly polluted wastewater, the dissolved oxygen is too high, the energy consumption is high, and the membrane fouling is easy to occur due to excessive aeration. Embodiment 3 of the present invention provides the concurrent oxygen type MBR sewage treatment method, adopts the concurrent oxygen type MBR sewage treatment equipment described in embodiment 2, and it comprises the following steps:

[0054] S1, wastewater enters the cyclone desander tank through the water inlet pipe, and the sewage is pretreated by the cyclone desander 201 to remove hard particles in the influent; the rotational speed of the agitator in the cyclone desander 201 is preferably 12~ 20r / min.

[0055] S2, the effluent from the swirling grit chamber enters the water distribution tank 300, and is filtered by the filter 301 to remove the particulate matter, insoluble organic matter and fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com