Interlayer silicon carbide microwave heat structure crucible and preparation method thereof

A technology of silicon carbide crucible and thermal structure, which is applied in the field of composite ceramic crucible preparation, can solve the problems of poor wave-absorbing performance and achieve the effect of improving wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

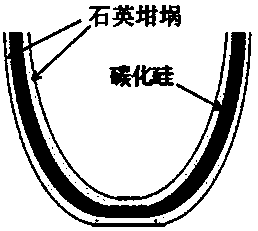

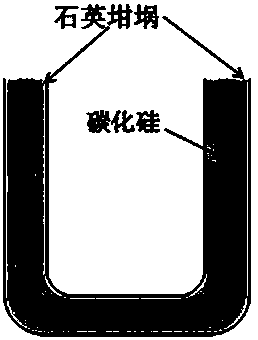

Image

Examples

Embodiment 1

[0027] (1) Select two arc-shaped quartz crucibles with the same shape and different sizes. The thickness of the quartz crucible is 3mm, and the gap width between the two quartz crucibles is 3-6mm. Immerse the quartz crucible in ethanol for ultrasonic cleaning (frequency 40KHZ, Time 2min), then put into the oven, dry at 60°C for 60min for later use;

[0028] (2) Preparation of silicon carbide slurry:

[0029] a. MgO-Al 2 o 3 -SiO 2 -B 3 o 2 Preparation of glass powder:

[0030] a1. Accurately weigh each glass powder raw material according to the following mass percentage: MgO 20%, Al 2 o 3 18%, SiO 2 52% and B 3 o 2 10%, of which MgO, Al 2 o 3 , SiO 2 and B 2 o 3 The particle sizes of the powders are: 80 μm, 50 μm, 70 μm and 40 μm. After preliminary mixing of the above raw materials, mix them in a ball mill for 2 hours, pass through an 80-mesh sieve, add the sieved mixed powder into a platinum crucible, and place Heating to 1500°C in a resistance furnace with ...

Embodiment 2

[0039] (1) Select two arc-shaped quartz crucibles with the same shape and different sizes. The thickness of the quartz crucible is 4.3mm, and the gap width between the two quartz crucibles is 5-10mm. Immerse the quartz crucible in ethanol for ultrasonic cleaning (frequency 40KHZ , time 10min), then put it into the oven, and dry at 80°C for 20min for later use;

[0040] (2) Preparation of silicon carbide slurry:

[0041] a.MgO-Al 2 o 3 -SiO 2 -B 3 o 2 Preparation of glass powder:

[0042] a1. Accurately weigh each glass powder raw material according to the following mass percentage: MgO 22%, Al 2 o 3 18%, SiO 2 52% and B 3 o 2 8%, of which MgO, Al 2 o 3 , SiO 2 and B 2 o 3 The particle sizes of the powders are: 50 μm, 40 μm, 70 μm and 30 μm. After preliminary mixing of the above raw materials, mix them in a ball mill for 5 hours, pass through a 110-mesh sieve, add the sieved mixed powder into a platinum crucible, and place Heating to 1600°C in a resistance fur...

Embodiment 3

[0051] (1) Select two arc-shaped quartz crucibles with the same shape and different sizes. The thickness of the quartz crucible is 7mm, and the gap width between the two quartz crucibles is 5-15mm. Immerse the quartz crucible in ethanol for ultrasonic cleaning (frequency 40KHZ, time 5min), then put it into the oven, and dry at 70°C for 30min for later use;

[0052] (2) Preparation of silicon carbide slurry:

[0053] a. MgO-Al 2 o 3 -SiO 2 -B 3 o 2 Preparation of glass powder:

[0054] a1. Accurately weigh each glass powder raw material according to the following mass percentage: MgO 22%, Al 2 o 3 18%, SiO 2 50% and B 3 o 2 10%, of which MgO, Al 2 o 3 , SiO 2 and B 2 o 3 The particle sizes of the powders are: 40 μm, 70 μm, 50 μm and 60 μm. After preliminary mixing of the above raw materials, mix them in a ball mill for 4 hours, pass through a 100-mesh sieve, add the sieved mixed powder into a platinum crucible, and place Heating to 1550°C in a resistance furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com