A kind of crushing walnut kernel extraction processing technology

A processing technology and walnut technology, which is applied in the field of processing technology for crushing walnuts and extracting kernels, can solve the problems of time-consuming, labor-intensive, and low shelling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

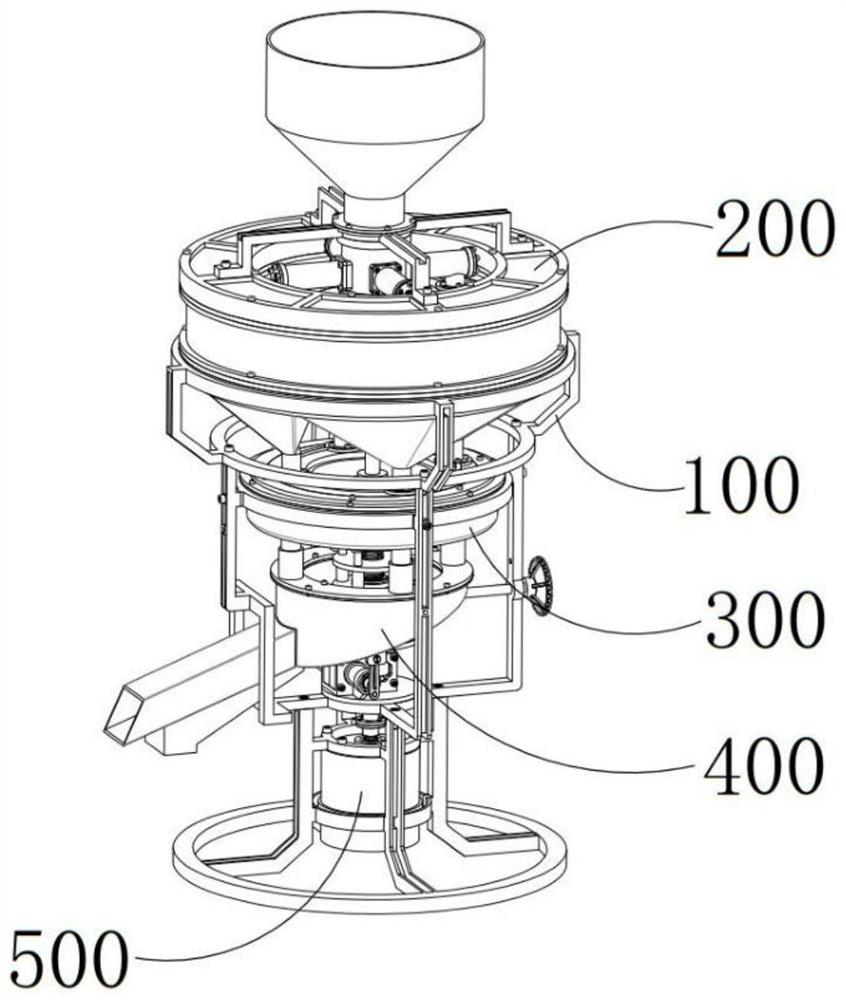

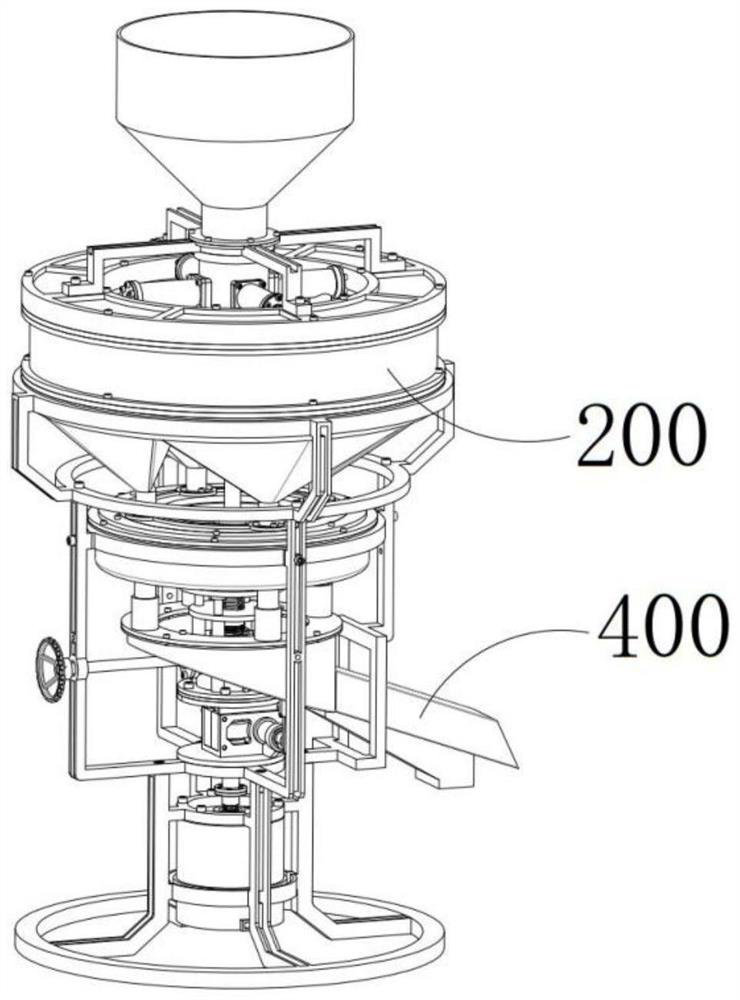

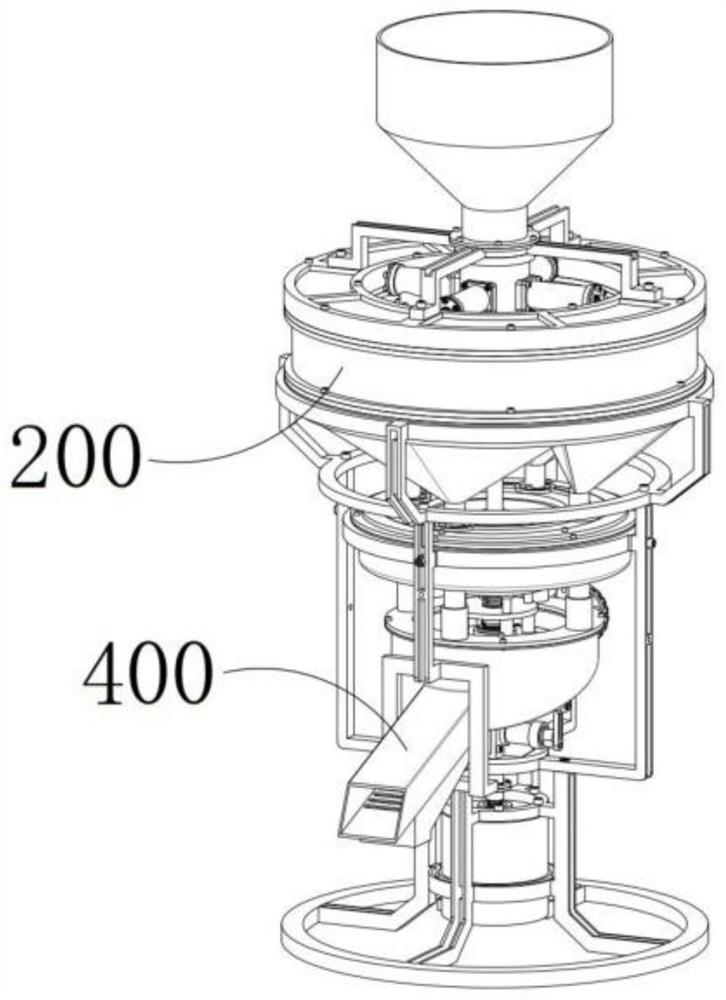

[0068] A kind of broken walnut kernel processing technology, its steps are:

[0069] (1) Rupture stage;

[0070] S1: The pushing mechanism 240 pushes the walnuts in the feeding hopper 220 to the centrifugal channel 216 in the breaking container 210 one by one;

[0071]The rupture vessel 210 includes an inner ring plate one 211 and an outer ring plate one 212 coaxially arranged, the outer ring plate one 212 is fixedly connected with the installation frame 100, and the inner ring plate one 211 and the outer ring plate one 212 are axially aligned. Arranged vertically and the diameter of the inner ring plate one 211 is smaller than the diameter of the outer ring plate one 212, the inner ring plate one 211 is located inside the outer ring plate one 212, and the upper and lower ends of the inner ring plate one 211 and the outer ring plate one 212 are the same The shaft is provided with an annular cage 213 for fixing the two, and the upper opening formed by the inner ring plate one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com