An Incrementally Constrained Multidirectional Forging Method for Silicon Carbide Whisker Reinforced Aluminum Matrix Composites

A silicon carbide whisker, multi-directional forging technology is applied in the field of warm forging to achieve the effects of reducing longitudinal cracking, avoiding cracking, and improving tensile strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

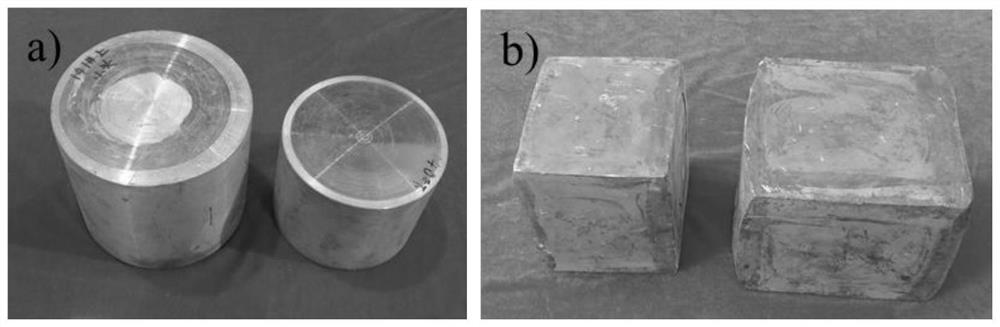

[0064] (1) Billet: Extruded cast silicon carbide crystal must enhance the aluminum alloy composite ingot (aluminum matrix 6061 aluminum alloy) and 12 mm thickness of 6061 aluminum alloy ring package to perform an interference fit, and welded at both ends 6061 aluminum alloy circular panel, has a coated blank having a diameter of 159 mm height of 154 mm;

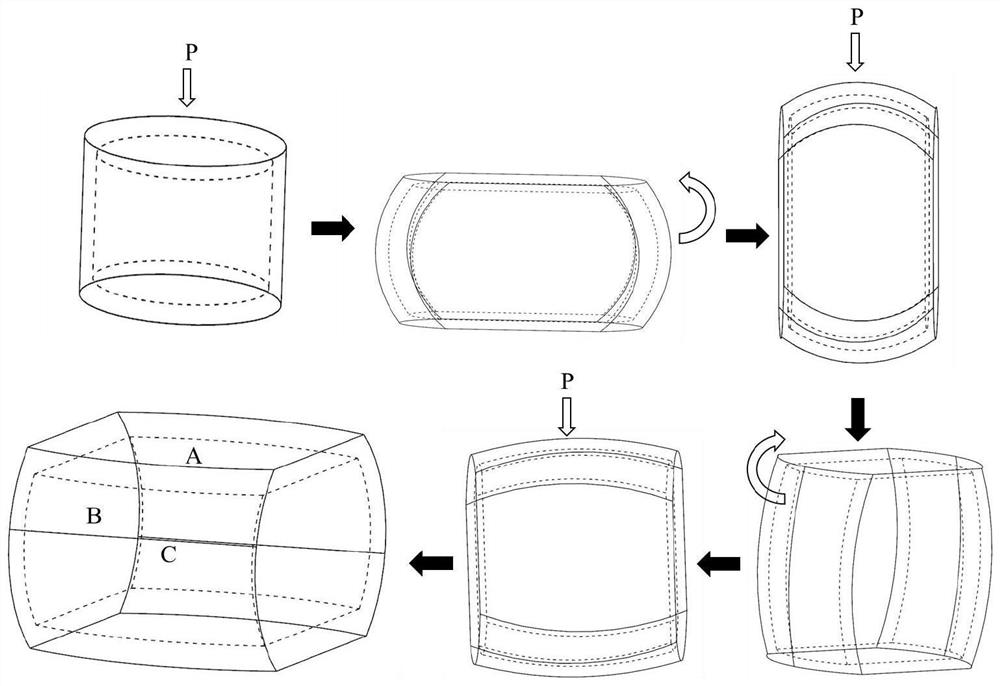

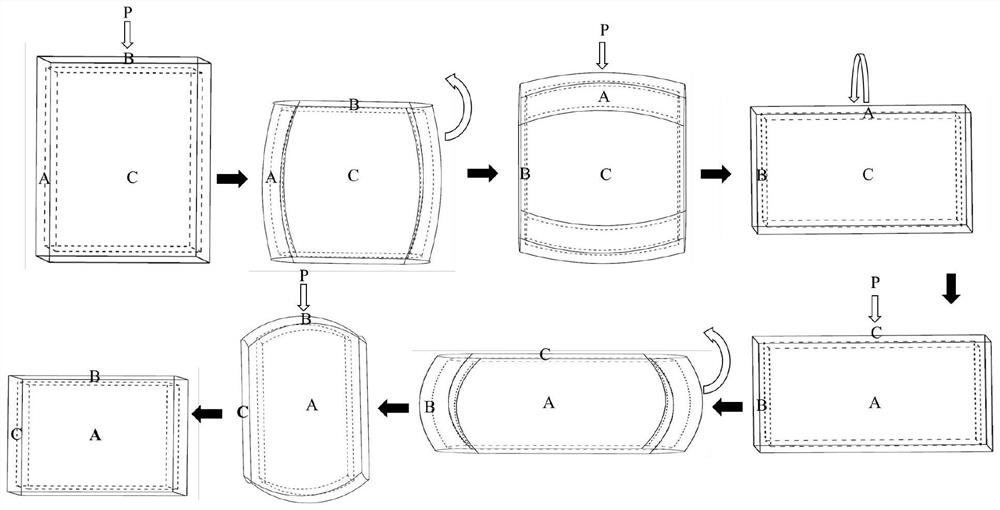

[0065] (2) Put the coating blank into the box-type resistor furnace, heating to 455 ° C and heats up 90 min, the upper and lower anvil is heated to 440 ° C, the upper anvil pressure is 10mm / s; the heated cylindrical blank is placed in After the anvil, multi-directional forging is made by anvil and a radvation. figure 1 As shown, the upsetting is first upset along the cylindrical ingot, the pressure is 30%, and then the amount of upsetting each other is vertically vertically, the amount is 25%, respectively; the cylinder is returned to the body bomb. After continuing 3 cycles, the three-way is one cycle, such as figure 2 As sh...

Embodiment 2

[0069] (1) Billet: Extruded cast silicon carbide crystals need to enhance the aluminum alloy composite ingot (the same as in Example 1) and 10 mm thickness of the 6061 aluminum alloy package for overseeing cooperation, and weld 6061 aluminum at both ends. Alloy circular plates, an aluminum-based composite coated blank having a diameter of 155 mm height of 150 mm;

[0070] (2) Put the coating blank into the box resistance furnace, heated to 455 ° C and heat insulation 90 min, the upper oscillat of the press is hot to 440 ° C, the upper vollation pressure is 10 mm / s; the heated cylindrical blank is placed in After the anvil, multi-directional forging is made by anvil and a radvation. figure 1 As shown, the upsetting is first upset along the cylindrical ingot, and the amount of pressure is 35%, and then the amount of upsetting each other vertically, the amount of pressure is 30%; the cylinder is returned to the cube. Continue 2 multi-directional forging, such as figure 2 As shown...

Embodiment 3

[0076] (1) Bar: Extruded Cast Siliconated silicon crystals need to enhance the aluminum alloy composite ingot (same as in Example 1) and 6061 aluminum alloy package of 8 mm thickness, and weld 6061 aluminum at both ends. The alloy circular plate, an aluminum-based composite coated blank having a diameter of 151 mm height of 146 mm;

[0077] (2) Put the coating blank into the box resistance furnace, heated to 460 ° C and heat insulation 90 min, the upper oscillator on the press is hot to 450 ° C, the rate of the anvil pressure is 8mm / s; the heated cylindrical blank is placed in After the anvil, multi-directional forging is performed by an anvil, first in the first radial direction of the cylindrical ingot, the amount of pressure is 35%, and then along the second radial direction perpendicular to the first radial direction. Upset, the amount of pressure is 25%, and finally the axial direction is upset, the amount of pressure is 25%; the cylinder will return the cylindrical part to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com