Enhanced activated sludge method sewage treatment process

An activated sludge method and sewage treatment technology, applied in water/sludge/sewage treatment, biological water/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of difficult maintenance of high sludge concentration and long sludge age, failure to ensure stable and reliable operation of the system, etc., to achieve the effect of improving the flow state of the reactor, reducing degradation, and enhancing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

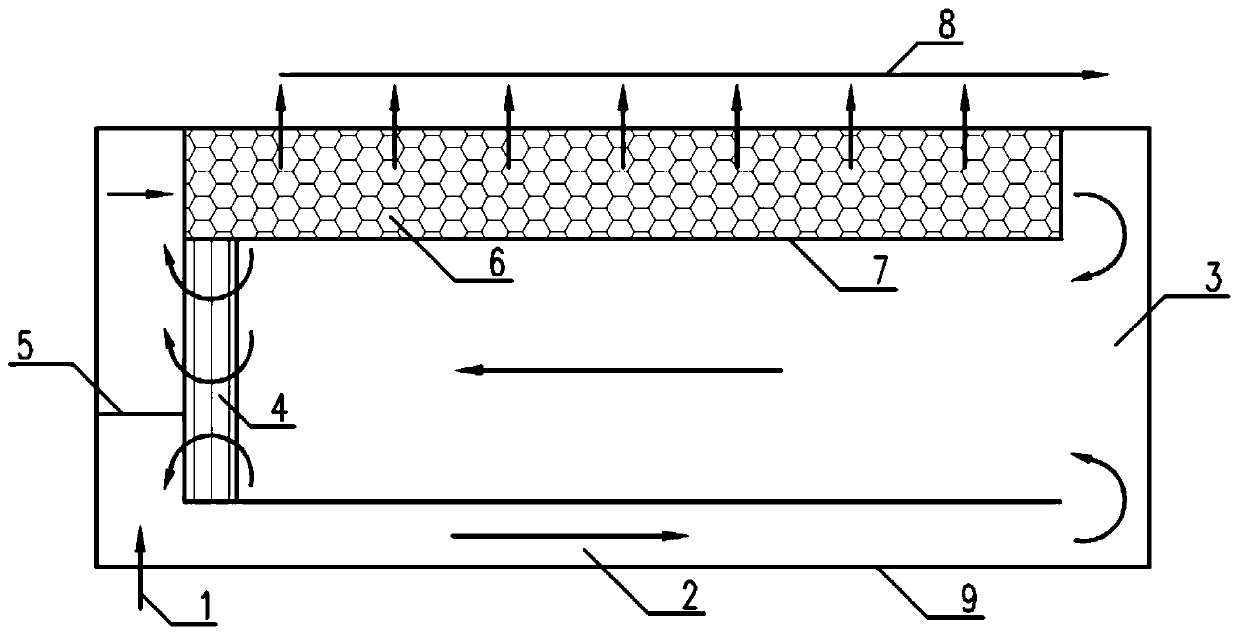

[0038] Concrete implementation case 1, the present invention provides a kind of enhanced activated sludge process sewage treatment process, and its realization method comprises the following steps: (1) sewage is through pretreatment (grid, grit chamber), removes larger suspended solids and grit , then enter the unit of the present invention---biochemical tank, the water quality requirement of influent TCOD:TN>4; (2) in the biochemical tank, the activated sludge concentration is 8000mg / L, and the sewage degrades synchronously within 12 hours of residence time COD, ammonia nitrogen, nitrate nitrogen, the effluent in the final clarification area meets the requirements of surface water type III water body, COD3 , the treated water volume is 1000m 3 / d, where the main aeration zone is 15m×4.4m×5m (length×width×height), the clarification zone is 12m×3.6m×4m (length×width×height), and the sludge stabilization zone (return channel) is below the clarification zone ), the air lift is lo...

specific Embodiment example 2

[0039] Concrete implementation case 2, the present invention provides a kind of enhanced activated sludge method sewage treatment process, and its realization method comprises the following steps: (1) this project is a standard improvement project, and the water inflow is 20000m 3 / d, part of which is the first-level A effluent of the upstream oxidation ditch, and part of which is the pretreated raw water, equipped with a carbon source (sodium acetate or ethanol, etc.) dosing device to ensure TCOD: TN>4; (2) Influent COD 3 , where the main aeration zone is 57.5m×12.8m×6m (length×width×height), the clarification zone is 52.5m×9.6m×5.0m (length×width×height), and the sludge stabilization zone (channel ), the air lift is located on one side of the clarification area, and the size of the air lift area is 11.6m × 1m × 6m (length × width × height); (4) the oxygen supply of the main aeration area is 176kgO 2 / h, as the influent concentration fluctuates, maintain a low dissolved oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com