Rare earth NM360 wide and thick steel plate and production method thereof

A production method and technology for steel plates, applied in the field of metallurgical plates, can solve the problems of long process flow, high cost and easy cracking during processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

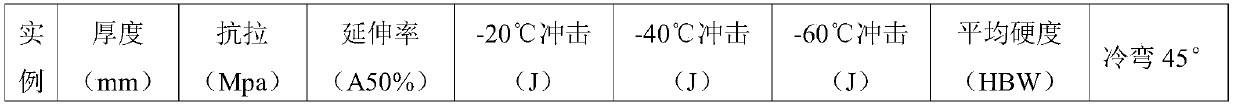

Examples

Embodiment 1

[0091] Embodiment 1, the preparation of rare earth NM360 wide and thick steel plate

[0092] The preparation of wide and thick steel plates in this embodiment adopts the following steps:

[0093]The raw material molten iron undergoes deep desulfurization of molten iron, blowing at the top and bottom of the converter, argon blowing in the ladle, refining outside the LF furnace, RH vacuum treatment and continuous casting to obtain a 300mm thick slab; the thick slab is heated in a heating furnace, and the heating temperature of the slab is 1190 ℃, heating time 290min, heat preservation 50min and then enter the rolling process; the rolling start temperature of the first stage of rolling is 1187℃, the slab is widened in the longitudinal direction, and the relative reduction ratio of a single pass is controlled at least 20 times. % or more, when the thickness of the rolled piece is 161mm (the thickness of the finished product is 2.3 times), wait for the temperature on the roller tab...

Embodiment 2

[0094] Embodiment 2, preparation of rare earth NM360 wide and thick steel plate

[0095] The preparation of wide and thick steel plates in this embodiment adopts the following steps:

[0096] The implementation of smelting and continuous casting is the same as in Example 1, and a 250mm thick slab is obtained; the thick slab is heated in a heating furnace, the slab heating temperature is 1218°C, the slab heating time is 278min, and the rolling process is entered after 50min of heat preservation; the first The stage rolling temperature is 1200°C, and the slab is widened in the length direction. The relative reduction ratio of a single pass is controlled at 20% or more in at least two passes. When the thickness of the rolled piece is 125mm (2.5 times the thickness of the finished product), the roll Wait until the temperature reaches 890 °C on the road, and then carry out the second stage of finish rolling. The final rolling temperature is 810 °C, and the thickness of the finished...

Embodiment 3

[0097] Embodiment 3, preparation of rare earth NM360 wide and thick steel plate

[0098] The preparation of wide and thick steel plates in this embodiment adopts the following steps:

[0099] The implementation of smelting and continuous casting is the same as in Example 1, and a 250mm thick slab is obtained; the thick slab is heated in a heating furnace, the slab heating temperature is 1197°C, the slab heating time is 239min, and the rolling process is entered after 50min of heat preservation; the first The stage rolling temperature is 1225°C, and the relative reduction rate of a single pass is controlled at least 20% for at least two passes. When the thickness of the rolled piece is 60mm (3 times the thickness of the finished product), the temperature on the roller table is 917°C. Then the second stage of finish rolling is carried out, the final rolling temperature is 790°C, and the thickness of the finished steel plate is 30mm; Slow cooling off the production line; after s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com