Surface treatment method applied to titanium or titanium alloy dental implant

A technology for dental implants and surface treatment, applied in dentistry, dental implants, medical science, etc., can solve the problems of inability to completely remove residual particles, reduced biological activity of implants, strong sulfuric acid corrosion hazards, etc., to speed up the speed of osseointegration , the effect of promoting adhesion and improving surface bioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

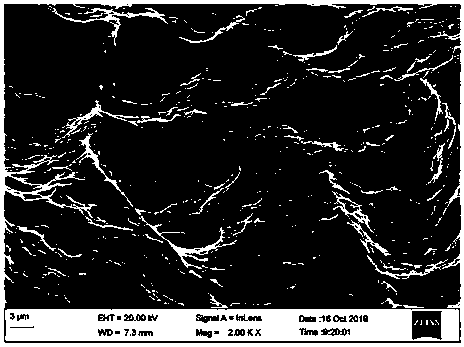

[0026] A surface treatment method applied to a TC4 titanium alloy dental implant, comprising the steps of:

[0027] (1) Polishing treatment: Use 800#, 1000# emery paper to polish the surface of the TC4 titanium alloy dental implant to remove impurities on the surface of the implant;

[0028] (2) Sandblasting: Sandblasting is performed on the surface of the polished TC4 titanium alloy dental implant under a pressure of 0.3Mpa. After the sandblasting is completed, ultrasonic cleaning (45KHz) with deionized water is used to assist washing for 20 minutes;

[0029] (3) Acid etching treatment: Prepare a certain proportion of mixed acid solution (1 mol / L oxalic acid, 5 mol / L phosphoric acid), and perform acid etching treatment on the TC4 titanium alloy dental implant after sandblasting at 85°C for 30 minutes;

[0030] (4) Washing treatment: the TC4 titanium alloy dental implant after the acid etching treatment was placed in an ultrasonic machine (45KHz), and washed with deionized wat...

Embodiment 2

[0033] A surface treatment method applied to a TC4 titanium alloy dental implant, comprising the steps of:

[0034] (1) Polishing treatment: Use 800#, 1000# emery paper to polish the surface of the TC4 titanium alloy dental implant to remove impurities on the surface of the implant;

[0035] (2) Sandblasting: Sandblasting is performed on the surface of the polished TC4 titanium alloy dental implant under a pressure of 0.4Mpa. After the sandblasting is completed, ultrasonic cleaning (50KHz) with deionized water is used to assist washing for 20 minutes;

[0036] (3) Acid etching treatment: prepare a certain proportion of mixed acid solution (0.4mol / L oxalic acid, 1.5mol / L phosphoric acid), and perform acid etching treatment on the TC4 titanium alloy dental implant after sandblasting at 85°C for 30 minutes;

[0037] (4) Washing treatment: the TC4 titanium alloy dental implant after the acid etching treatment was placed in an ultrasonic machine (50KHz), and washed with deionized w...

Embodiment 3

[0040] A surface treatment method applied to a TC4 titanium alloy dental implant, comprising the steps of:

[0041] (1) Polishing treatment: Use 1000#, 2000# emery paper to polish the surface of the TC4 titanium alloy dental implant to remove impurities on the surface of the implant;

[0042] (2) Sandblasting: Sandblasting is performed on the surface of the polished TC4 titanium alloy dental implant under a pressure of 0.4Mpa. After the sandblasting is completed, use deionized water ultrasonic (65KHz) to assist washing for 20 minutes;

[0043] (3) Acid etching treatment: prepare a certain proportion of mixed acid solution (2.5 mol / L oxalic acid, 8.5 mol / L phosphoric acid), and perform acid etching treatment on the TC4 titanium alloy dental implant after sandblasting at 85°C for 30 minutes;

[0044] (4) Washing treatment: the TC4 titanium alloy dental implant after the acid etching treatment was placed in an ultrasonic machine (65KHz), and washed with deionized water for 30 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com