A composite scale dissolution and scale prevention method for downhole coalbed methane

A technology for coalbed methane wells and scale dissolution, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of unrelieved scaling and cathodic protectors that cannot fully achieve the protection effect, and achieve good results The effect of the scale dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

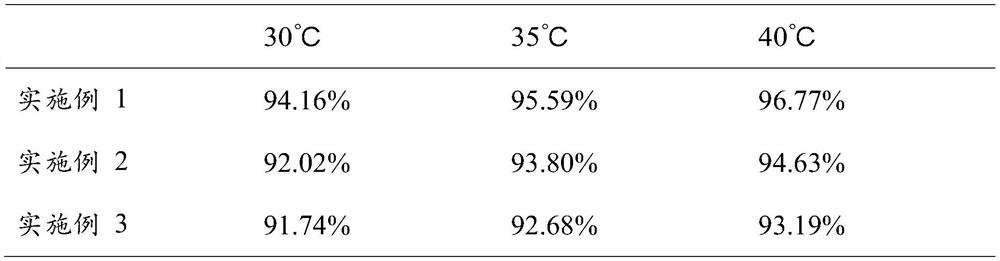

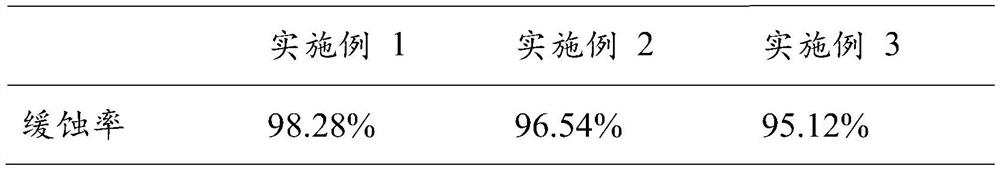

Embodiment 1

[0023] This embodiment provides a composite scale dissolving agent for downhole coalbed methane, including the following components: 80 parts of main agent, 18 parts of iron ion stabilizer, and 2 parts of corrosion inhibitor;

[0024] Among them, the main agent of scale dissolution is hydrochloric acid with a mass fraction of 16%; the iron ion stabilizer is citric acid and acetic acid in a ratio of 1:2 by mass; the corrosion inhibitor is polyaspartic acid and cycloalkylimidazoline It is compounded with urotropine according to the mass ratio of 1:3:6;

[0025] Preparation steps of the coalbed methane downhole composite scale-dissolving agent: at room temperature, add the main scale-dissolving agent, iron ion stabilizer, and corrosion inhibitor into the beaker in sequence according to the recipe amount and stir evenly to obtain the coalbed methane downhole composite scale-dissolving agent.

Embodiment 2

[0027] This embodiment provides a composite scale dissolving agent for downhole coalbed methane, including the following components: 87 parts of main agent, 12 parts of iron ion stabilizer, and 1 part of corrosion inhibitor;

[0028] Among them, the main agent for dissolving scale is hydrochloric acid with a mass fraction of 18%; the iron ion stabilizer is a mixture of citric acid and acetic acid in a mass ratio of 1:2; The product is compounded according to the mass ratio of 1:3:6;

[0029] Preparation steps of the coalbed methane downhole composite scale dissolving agent: at room temperature, add the main scale dissolving agent, iron ion stabilizer, and corrosion inhibitor to the beaker in sequence according to the formula amount and stir evenly to obtain the coalbed methane downhole composite scale dissolving agent;

Embodiment 3

[0031] This embodiment provides a composite scale dissolving agent for downhole coalbed methane, including the following components: 90 parts of main agent, 7 parts of iron ion stabilizer, and 3 parts of corrosion inhibitor;

[0032] Among them, the main agent of scale dissolution is hydrochloric acid with a mass fraction of 20%; the iron ion stabilizer is citric acid and acetic acid in a ratio of 1:2 by mass; the corrosion inhibitor is composed of polyaspartic acid and cycloalkylimidazoline It is compounded with urotropine according to the mass ratio of 1:3:6;

[0033] Preparation steps of the coalbed methane downhole composite scale dissolving agent: at room temperature, add the main scale dissolving agent, iron ion stabilizer, and corrosion inhibitor to the beaker in sequence according to the formula amount and stir evenly to obtain the coalbed methane downhole composite scale dissolving agent;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com