System for comprehensive synergetic treatment on titanium dioxide rotary kiln calining tail gas and method of system

A titanium dioxide and rotary kiln technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of wet smoke plume discharge, avoid wear and corrosion, solve colored smoke plumes, and improve energy utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below in conjunction with specific embodiments, so that those skilled in the art can understand.

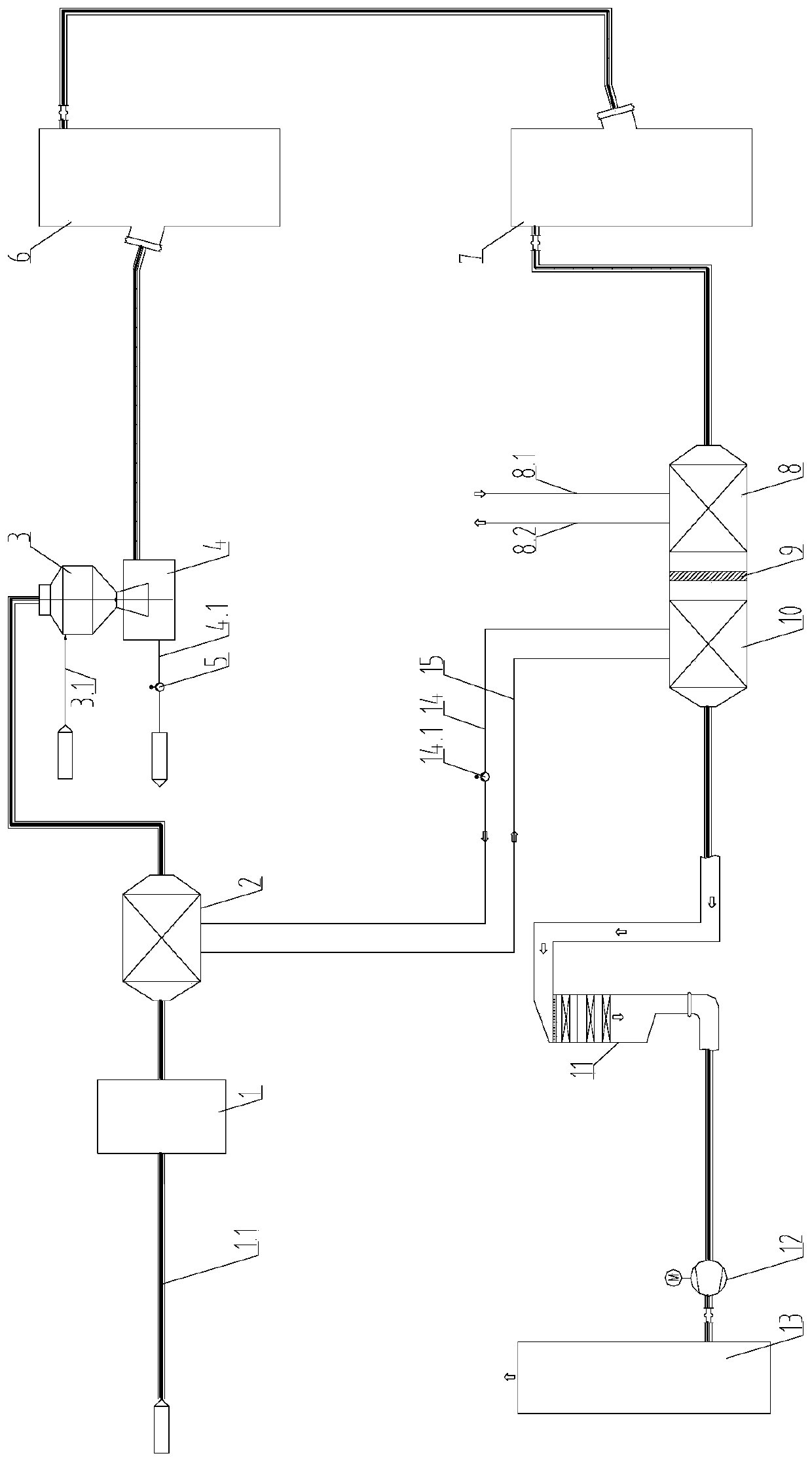

[0053] Such as figure 1 The system shown is a comprehensive and coordinated treatment of exhaust gas from the calcination of a titanium dioxide rotary kiln. The system includes a high-temperature bag filter 1. A filter tube is installed inside the high-temperature bag filter 1. The filter tube is a ceramic fiber or metal filter tube. Outside a single filter tube The diameter is 130-155mm, the inner diameter is 100-120mm, the length is 2.5-5m, and the temperature range of the filter tube is 200-600°C.

[0054] The side wall of the high-temperature bag filter 1 is externally connected with a calcined tail gas pipeline 1.1, and the high-temperature bag filter 1 is connected to a flue gas cooler 2 through the pipe, and the flue gas cooler 2 is connected to the top of the Venturi acid concentrator 3, and the venturi The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap